What is a Coil Spring’s Diameter?

Definition of Coil Spring Diameter

It is the “width” of a helical spring’s coils.

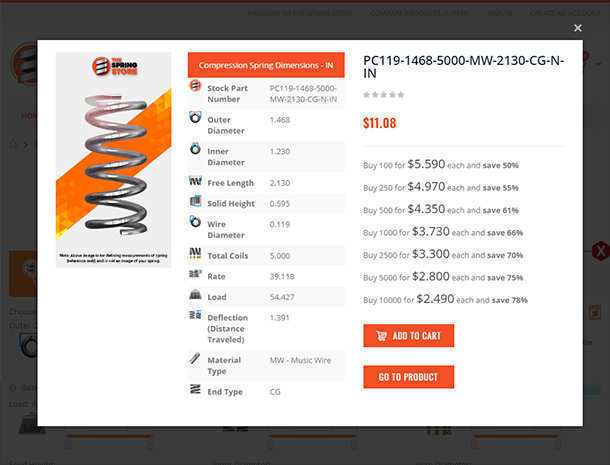

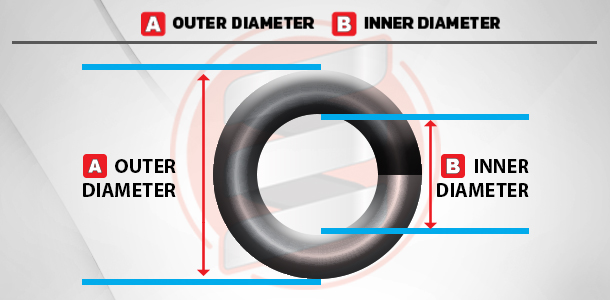

Today we want to share a few essential facts and useful information regarding the diameter of your coil spring. When it comes to measuring your spring’s coil diameter, you must determine which diameter is the one being measured. There is outer diameter and inner diameter. To understand the difference note the following:

Outer Diameter (OD) is the width of your spring measured from outside the coil. Knowing this measurements is very important to make sure your spring fits in your application, specially, when it is inserted into a hole or tube.

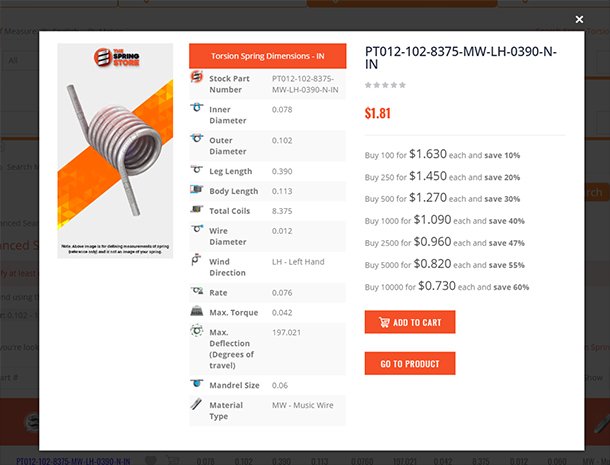

The Inner Diameter (ID) is the width of the “hole” at the center of the coils. Knowing this measurement will help you determine if the spring will fit over a shaft, mandrel, or tube.

The mean coil diameter (D) is right at the middle of the inner and outer diameters. It is measured from center of wire to center of wire.

Fact #1

Increasing the coil diameter will make a spring weaker while decreasing it will make it stronger.

Fact #2

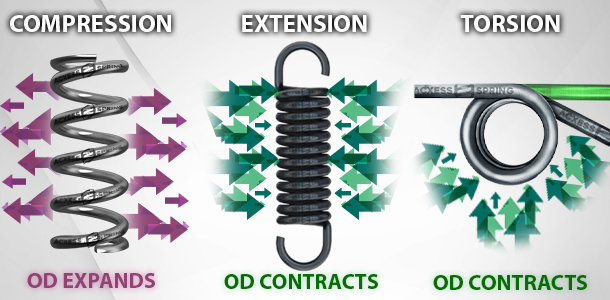

A compression spring’s coil diameter will expand a little during deflection. However, an extension spring’s coil diameter will contract during deflection. This is because one compresses while the other extends thus creating opposite effects and opposite results.

Fact #3

When it comes to torsional springs, they deflect radially so the coils are tightened during deflection. The result of this is the inner diameter contracting more noticeably than compression and extension springs.

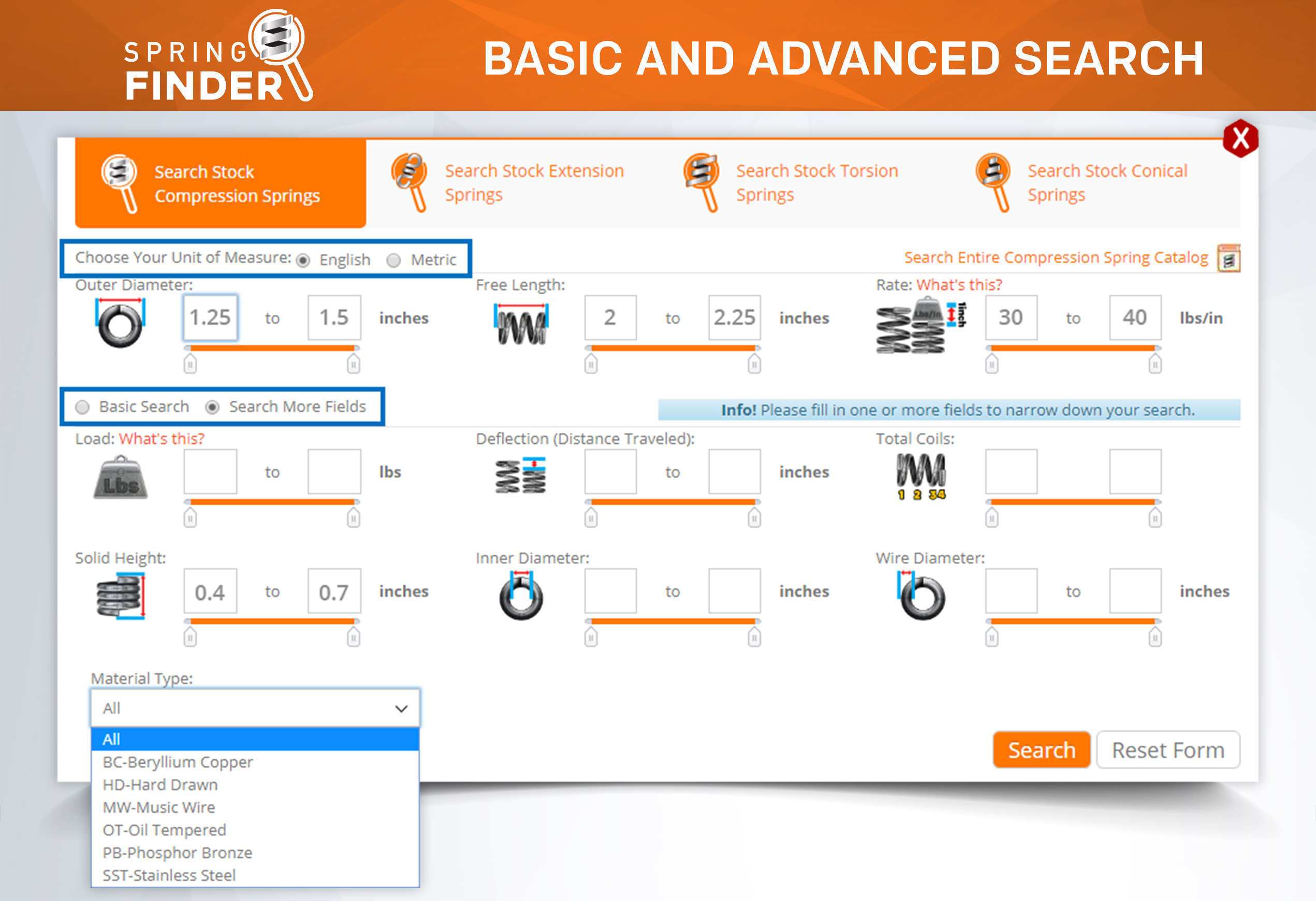

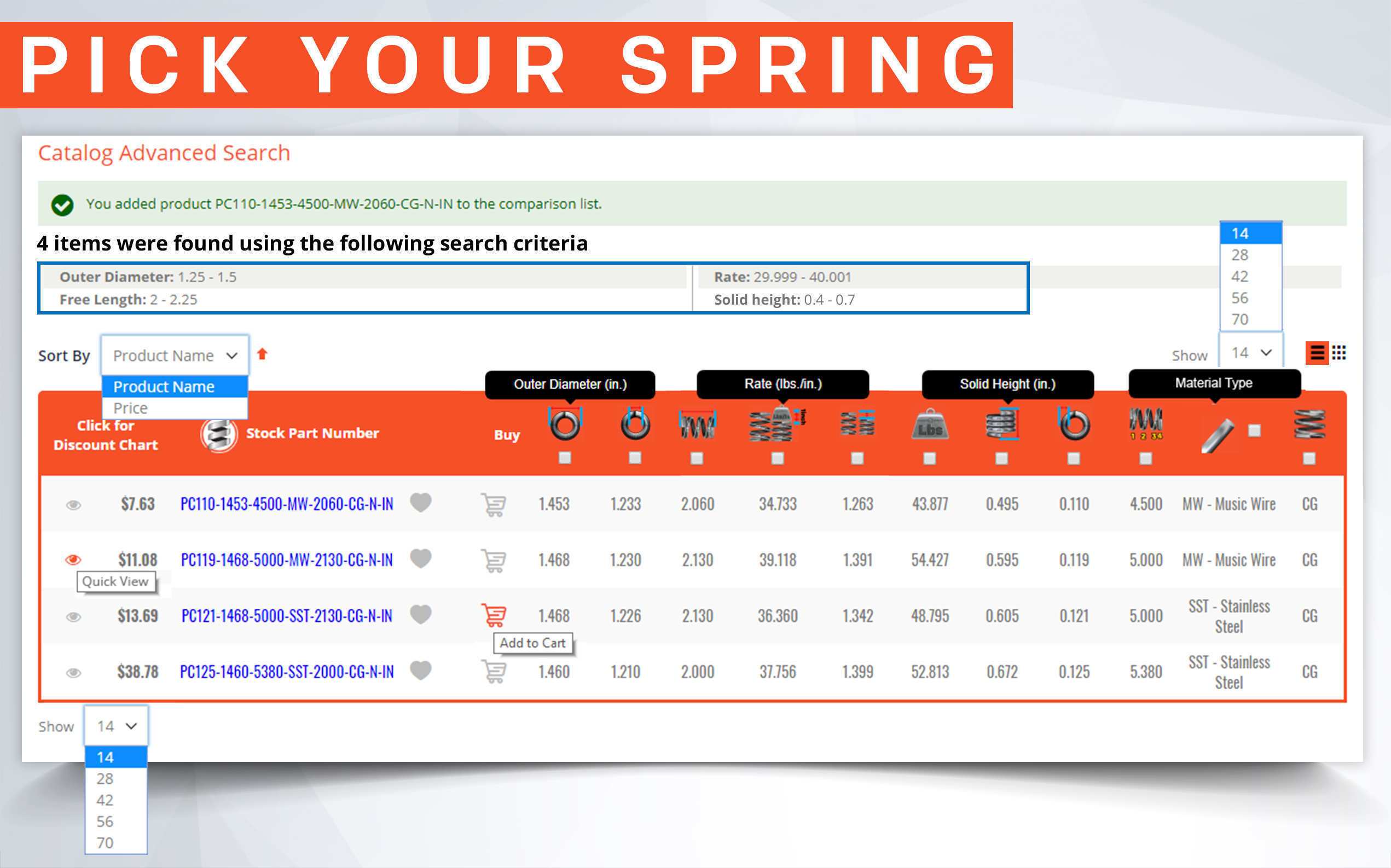

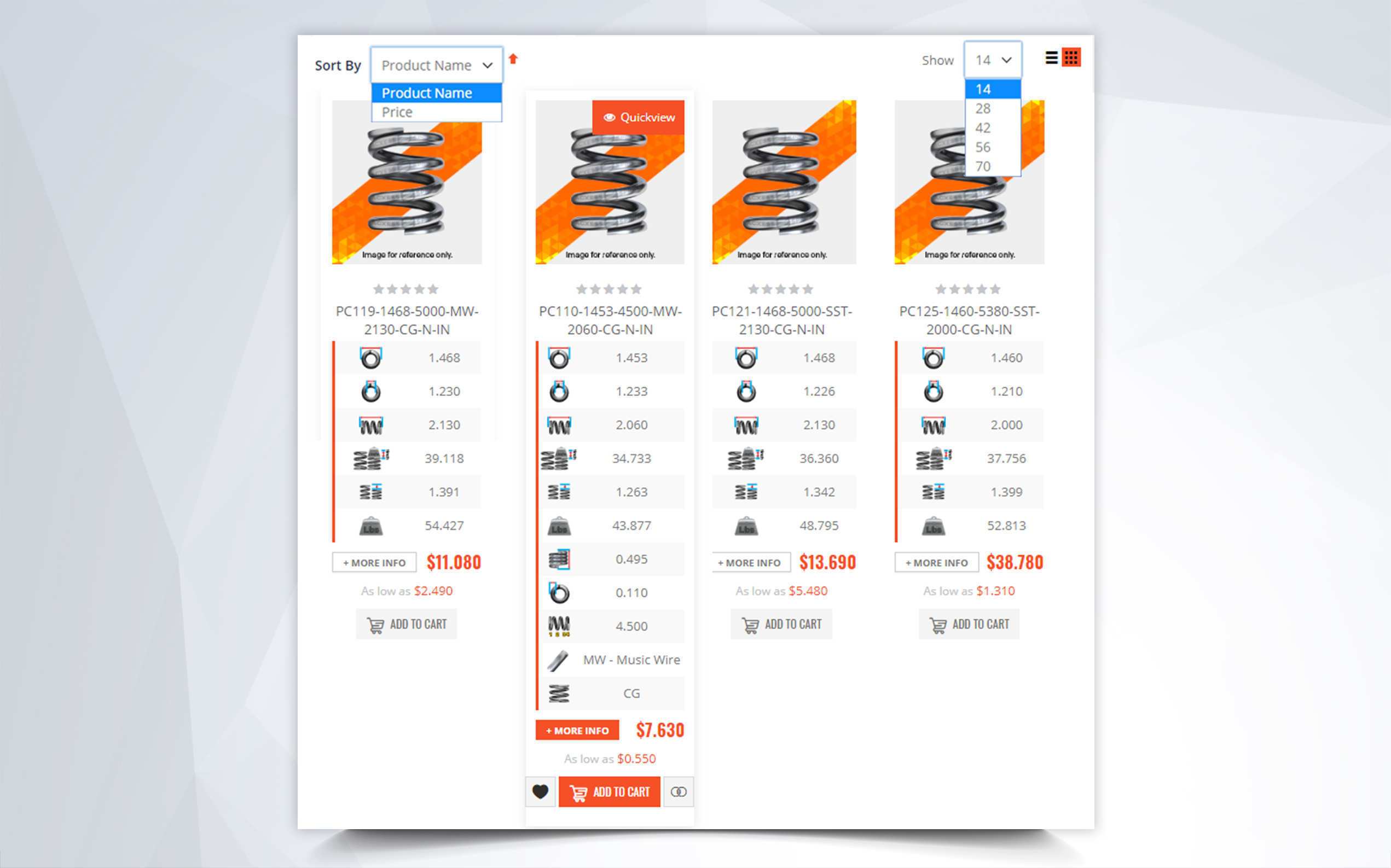

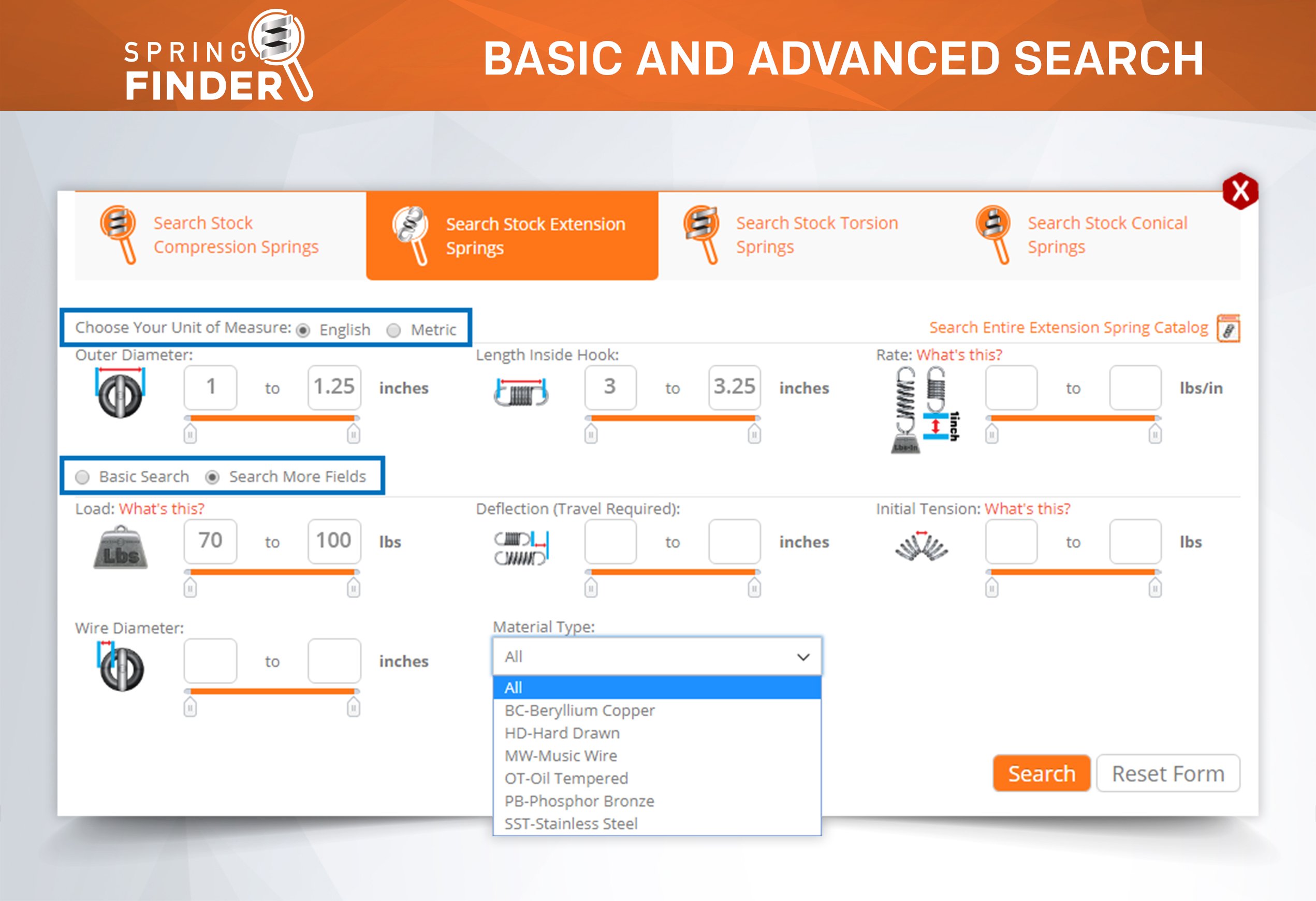

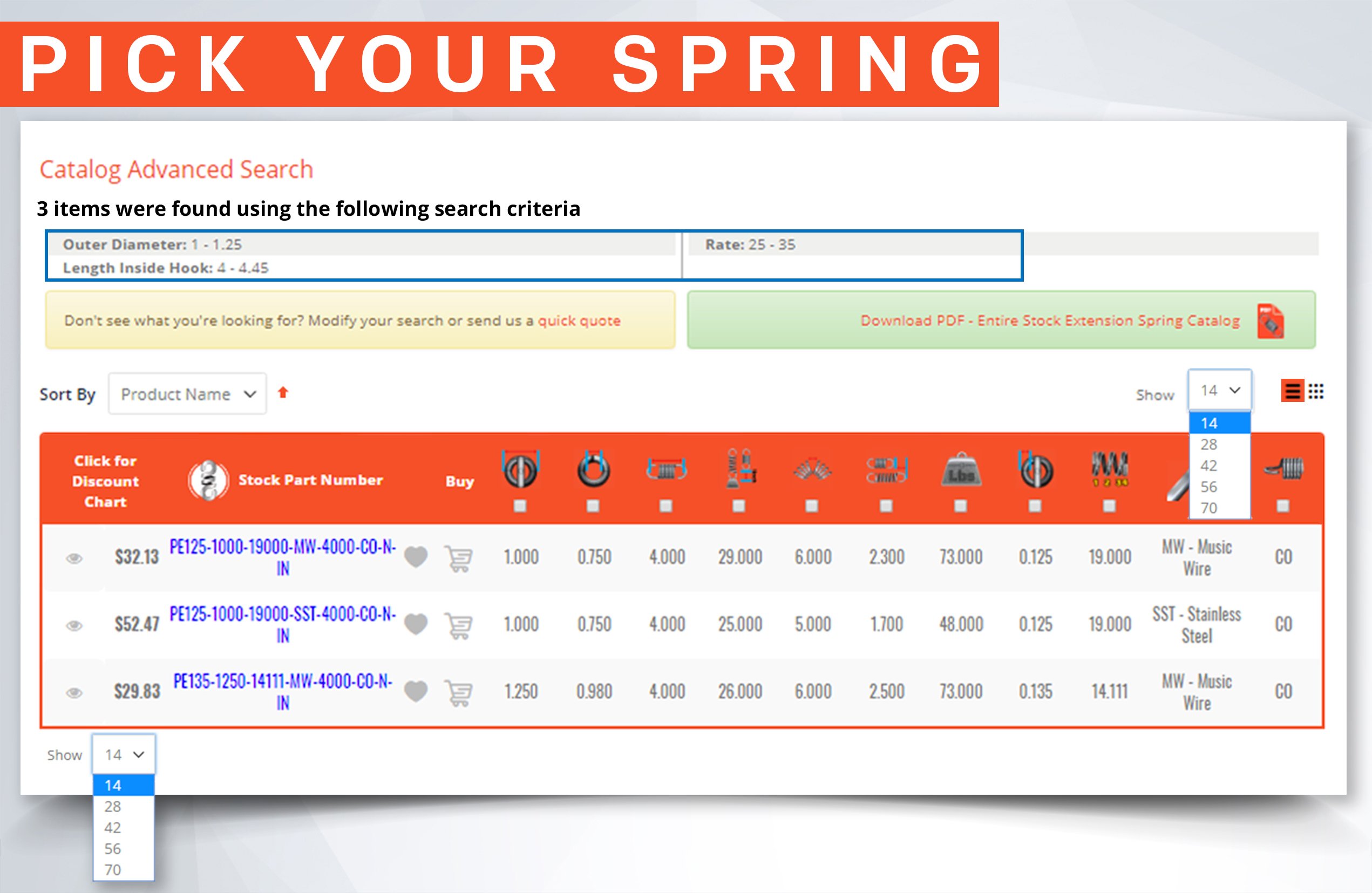

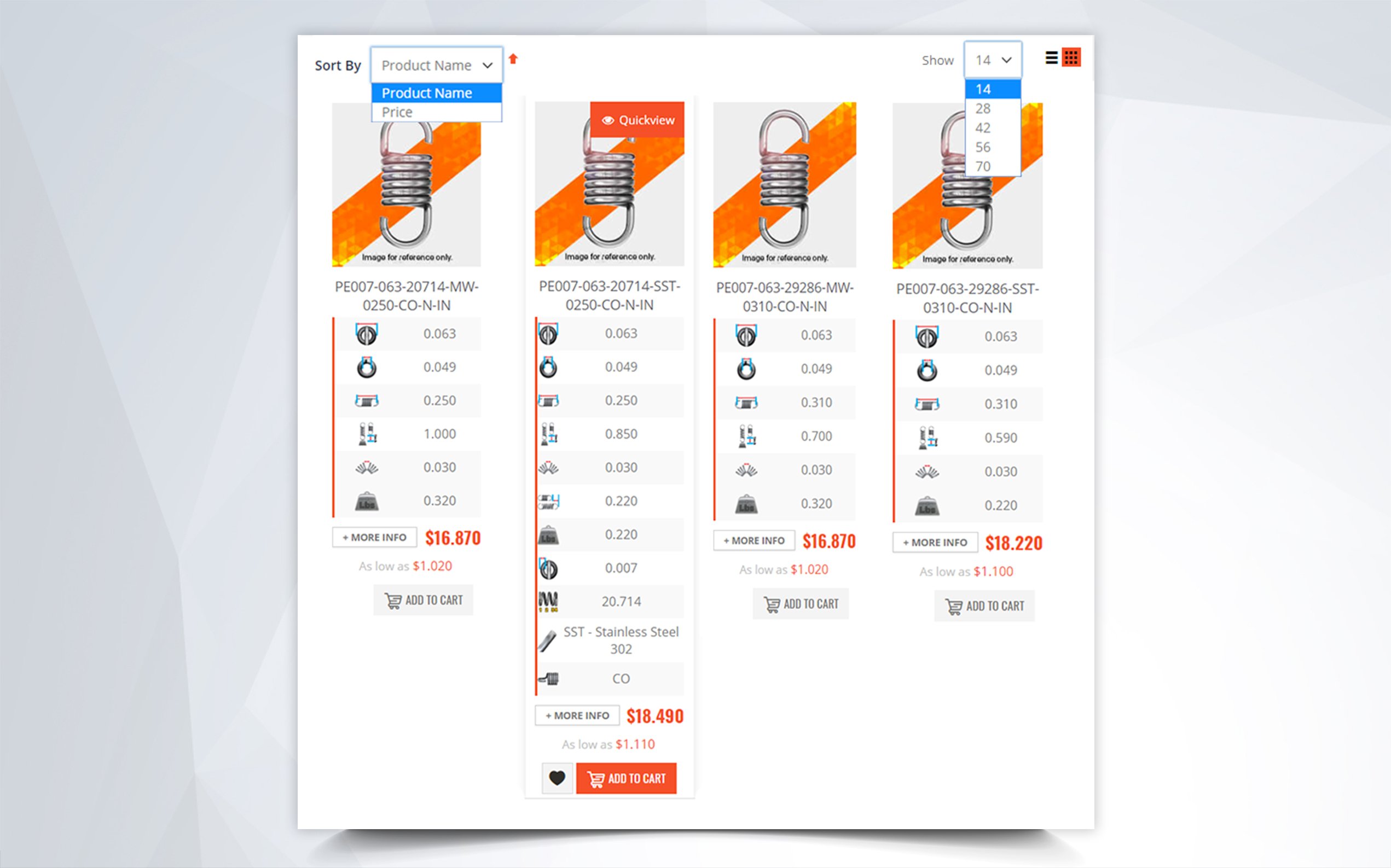

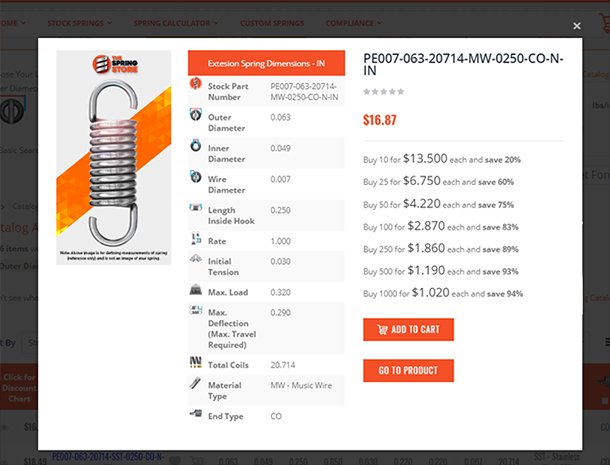

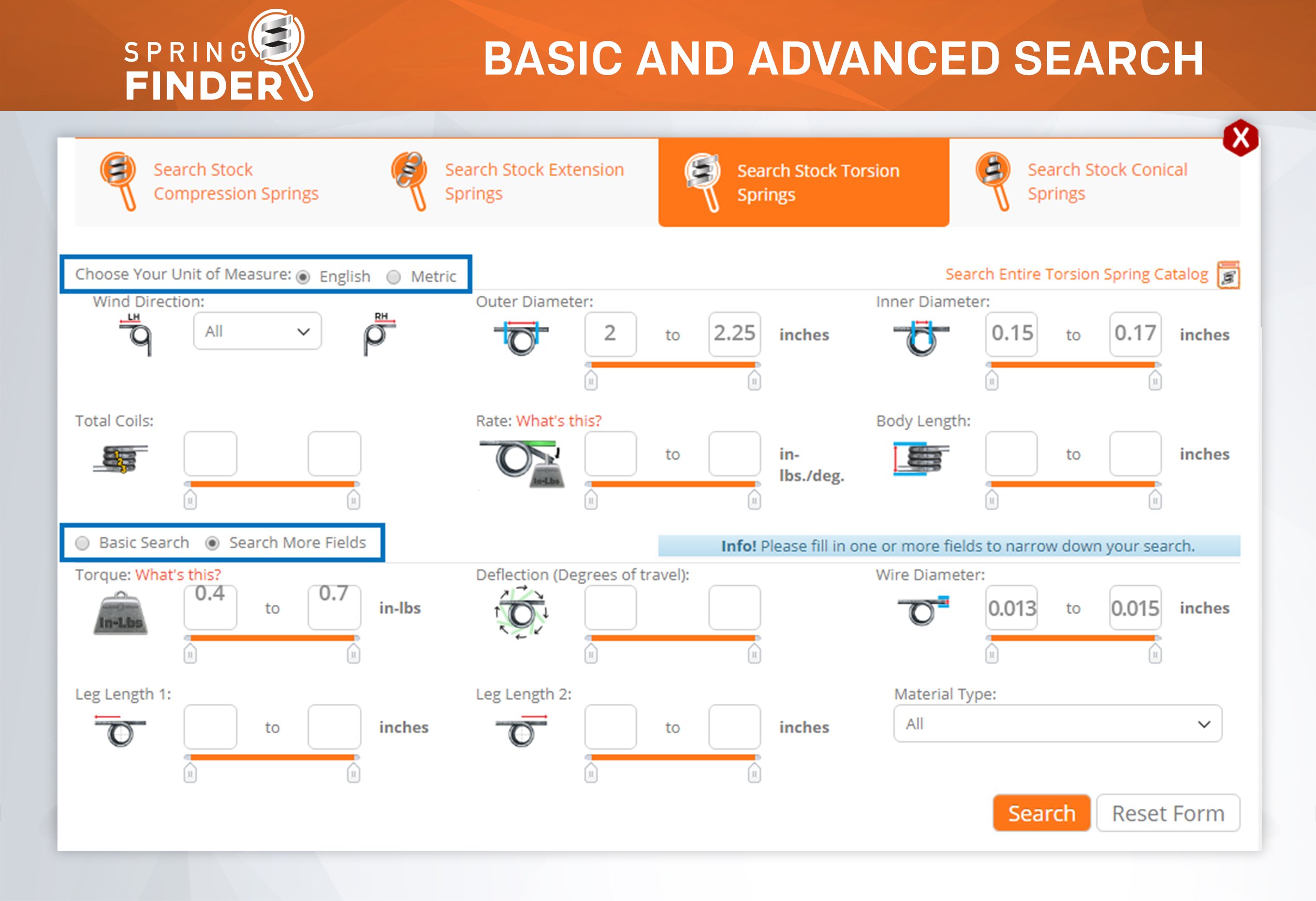

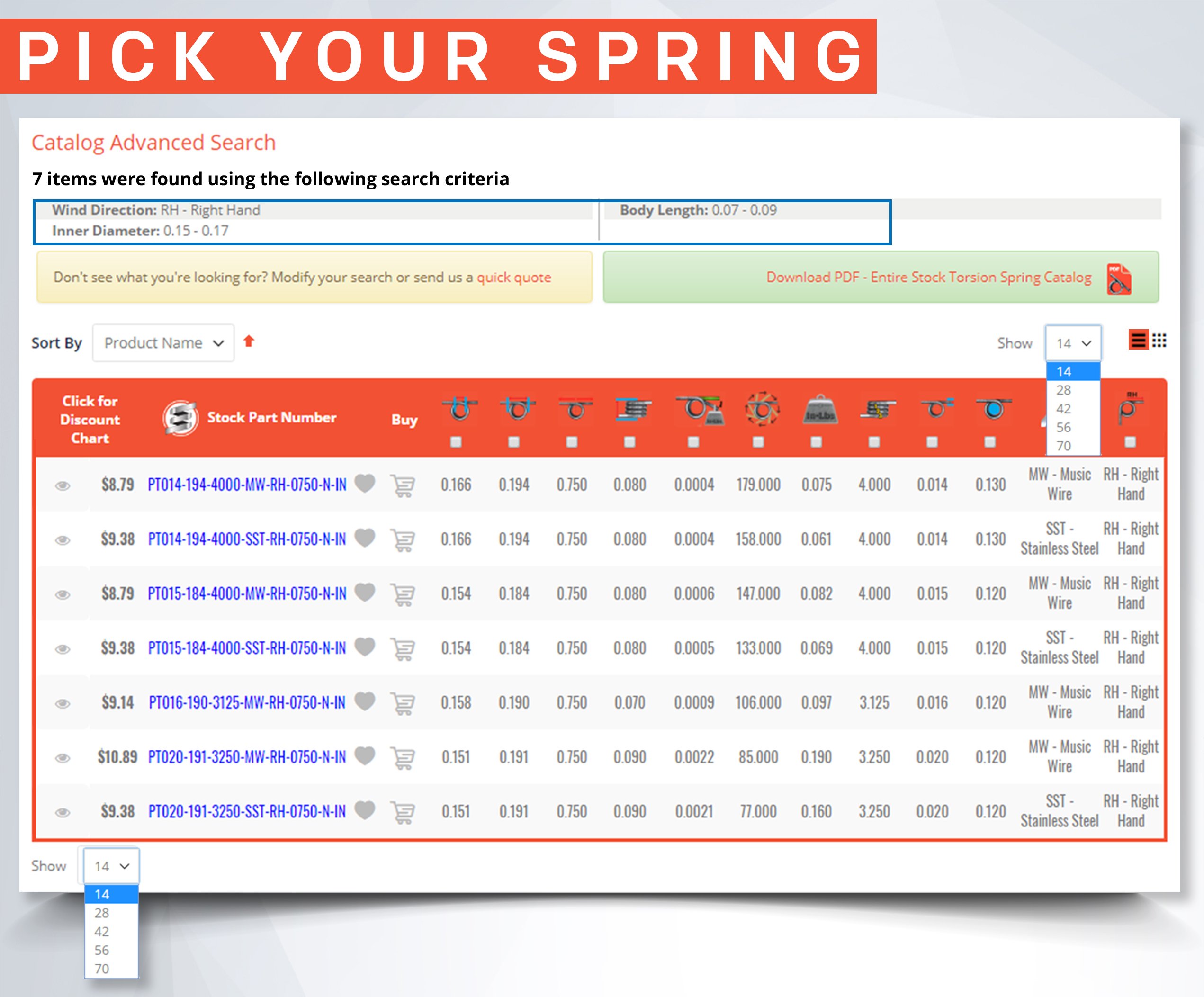

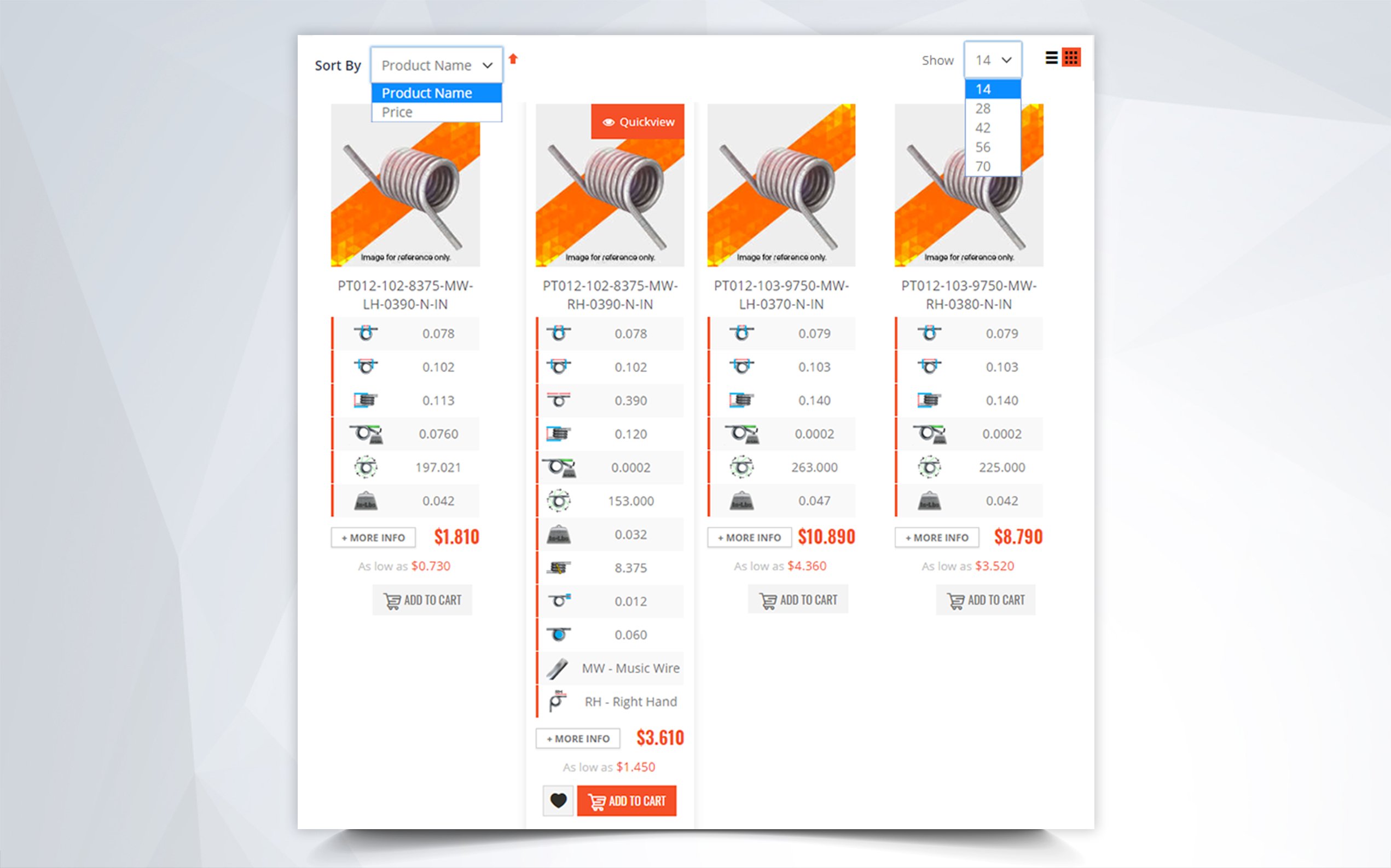

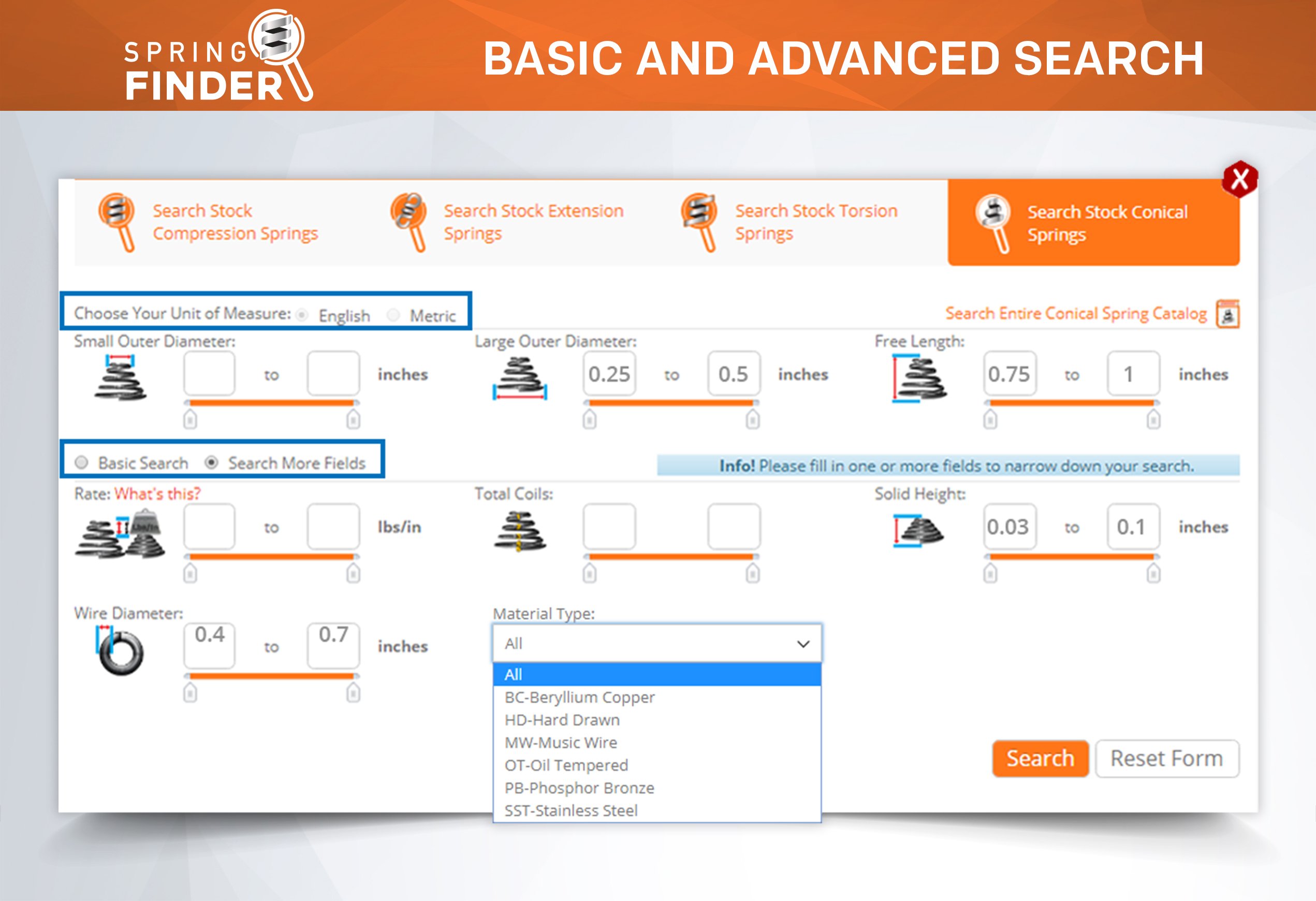

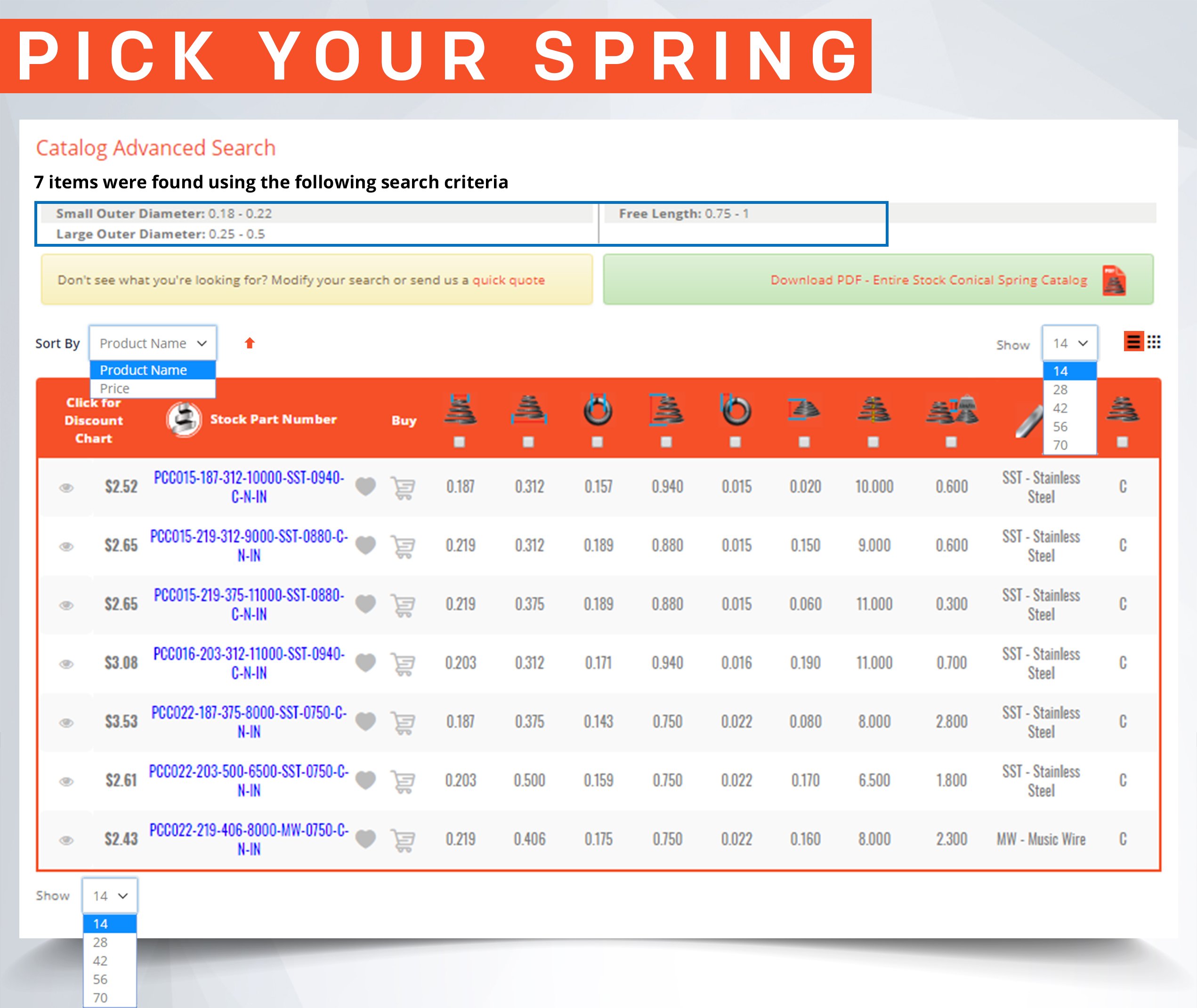

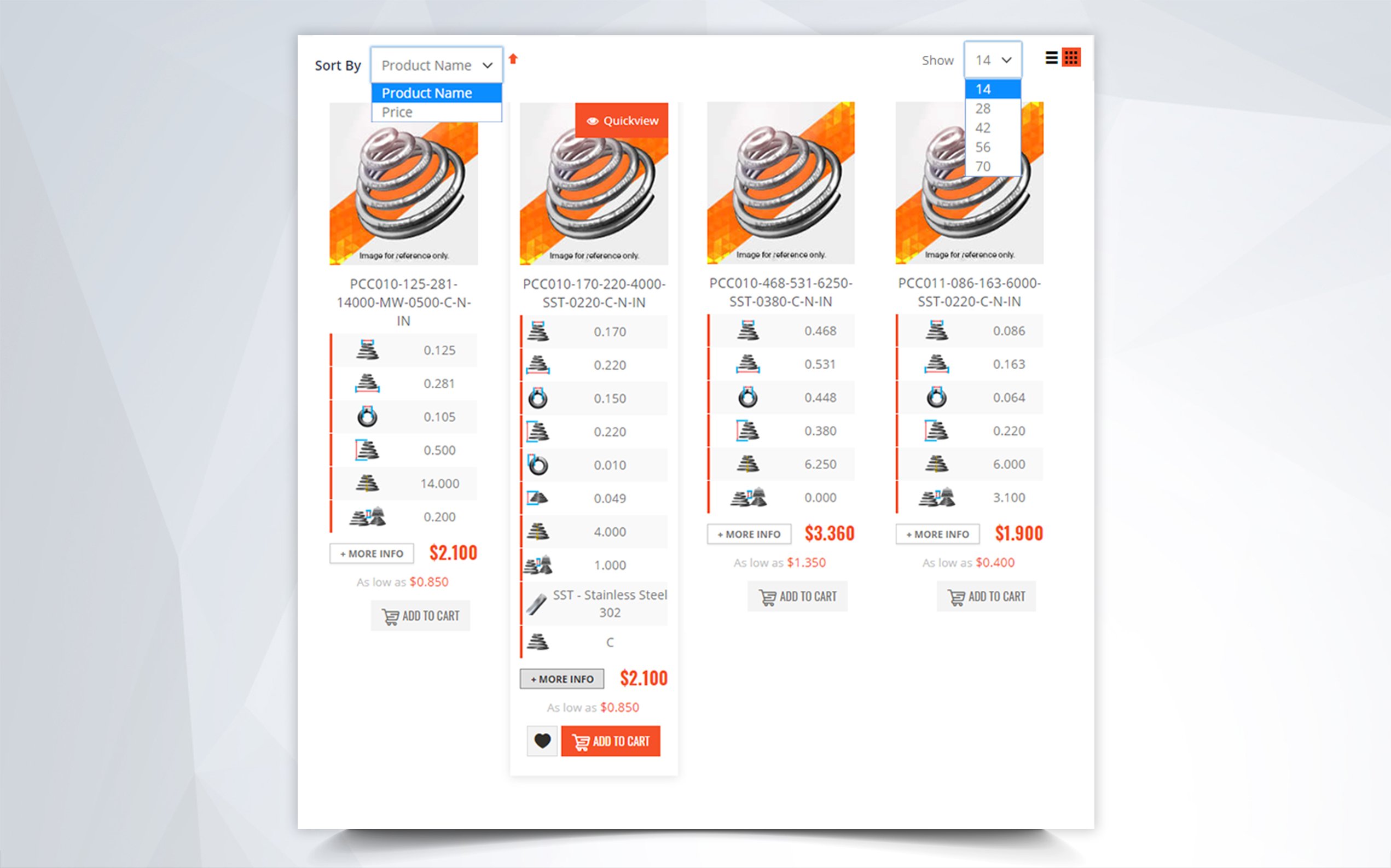

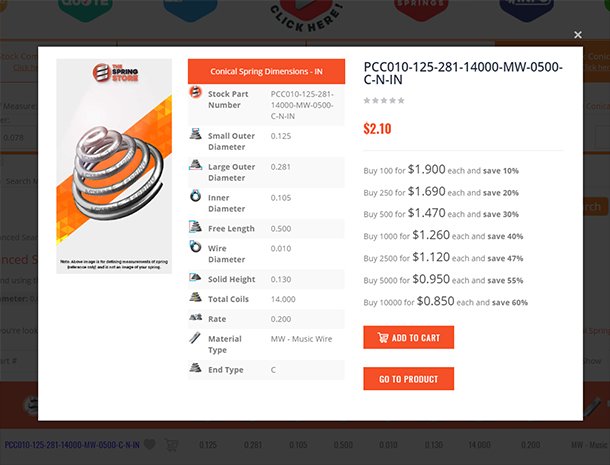

Understanding the different diameters used in designing a spring and selecting one is an important step. Once you determine at least one of these you can input it in the Spring Finder search so you can find the metal spring you need. If you can't find what you need in our stock, you can create your own spring with Spring Creator. For additional help or assistance in finding the ideal spring contact us today at: (951)276-2777.