Extension Springs Without Hooks

Extension Spring Ends

Extension springs also known as tension springs are used in a variety of devices and applications where a pulling mechanism takes place. The ends of these springs are usually connected to certain components that are to be involved in cycles of pulling on the tension spring and releasing the force so it can return to its free, pre-loaded or unloaded state. In order for this mechanism to take place the ends of extension springs must be attached to the components that will place the force that pulls it apart. This is usually done through hooks at the end of each tension spring that grab on to the ends of the load.

Common Stock Extension Spring Hooks: Machine Hooks and Cross Over Hooks

The most common type of ends for extension springs are machine and cross-over hooks. Machine hooks are not as pronounced as cross-over hooks and this makes them stronger. In order to create the machine hooks in extension springs three fourths of the end coil is bent out and you get a hook-like end that can be attached. Cross-over hooks are also somewhat common and their name describes the procedure used to complete this type of hook. These are created by lifting the last coil and then twisting the coil in toward the middle, which causes it to cross the center, hence the name. Due to this more pronounced hook it has a weaker point and may break more easily than machine hooks.

The Dangers of Tension Hook Failure.

Tension springs can also be called pull springs because of the motion they undergo. The constant pulling of a tension spring is not normally an issue if the right force and spring are paired up. However, the hooks of a tension spring can become a weak link if overused and with time, and other different factors can break and cause the spring to fail. Hook breakage can be quite dangerous because of all the force that the spring holds and then releases at the moment of breakage in one of the hooks. When a hook breaks it can cause the spring to propel and cause damage. That is why it is so important to ensure that the load and continuous force applied to the tension spring is adequate because the hooks are the weakest link and should not be forced to close to the limit.

Top Cause of Failure on Tension Springs

Hook Breakage is the number 1 cause of failure on any extension spring because all the tension of the spring relies on only 2 hooks that are bent and it can be too much for that single wire dimension to withstand. When purchasing a tension spring with hooks make sure that you take into consideration the amount of force and repetition of cycles that you will put that spring through. If the load is significant and constantly continuous the best option might be to acquire an extension spring without hooks.

No Hook Extension Springs

An extension spring without hooks looks very similar to a compressed, compression spring but it's function is the total opposite. Compression springs have pitch in between the coils and are meant to be pushed down, hence why there is space between the coils. Extension springs are meant to complete the opposite function and therefore start off with the coils touching and their function is to be pulled. Initial tension plays an important role in the function of an extension spring and therefore needs to be considered when calculating the max load it can withstand. For more on this READ THIS.

Extension Springs with No Hooks Have Prolonged Durability

In order to have a much more reliable and durable tension spring you can eliminate the hooks and use bolts to attach the ends into your device. By eliminating the hooks and inserting bolts into the spring, the tension is distributed around the threads of the bolt giving incredible biting down power around the bolt. This makes the extension springs without hooks last longer since the weakest part of the hook has been removed and the ends are fastened around many threads providing more resistance and resilience.

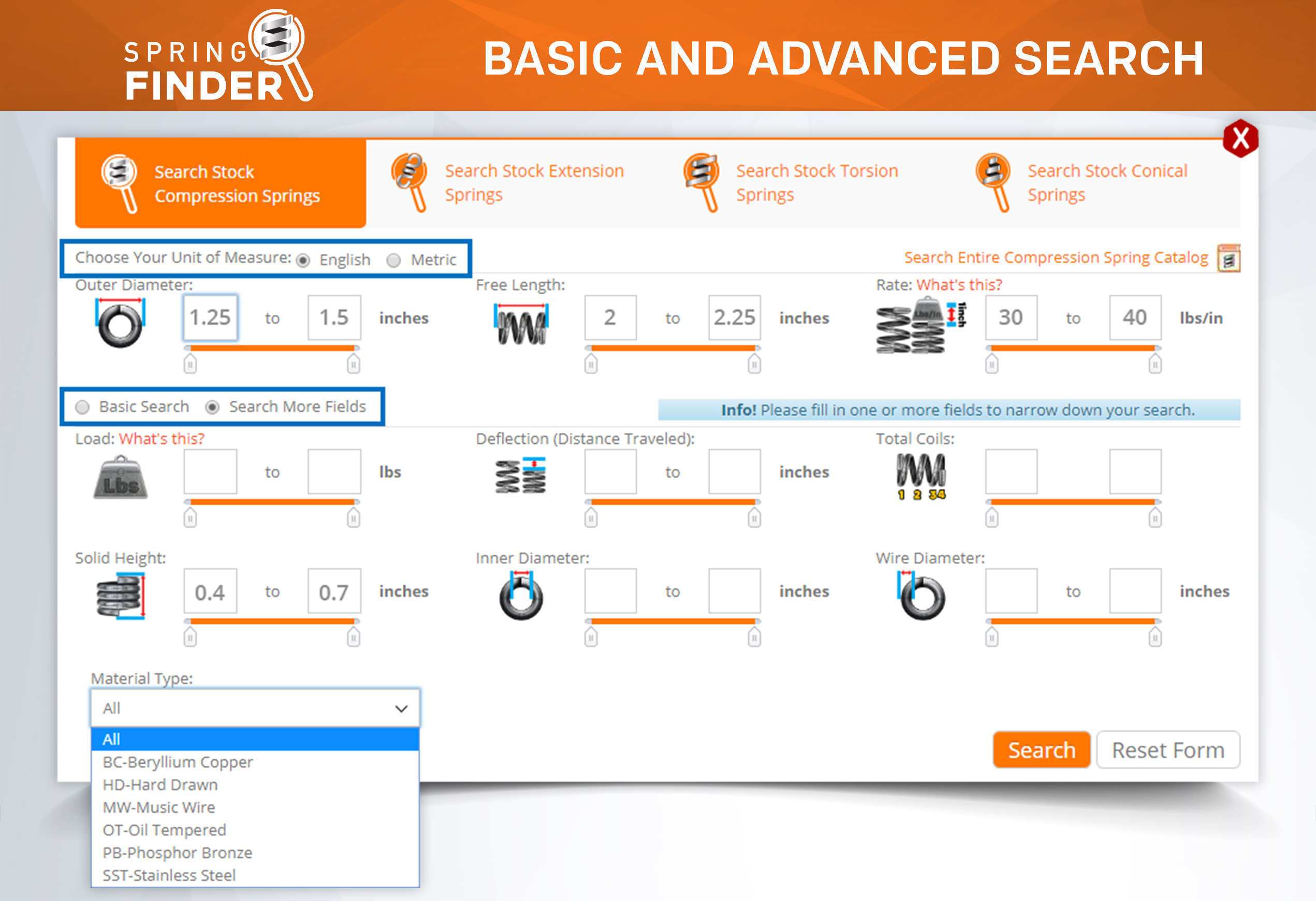

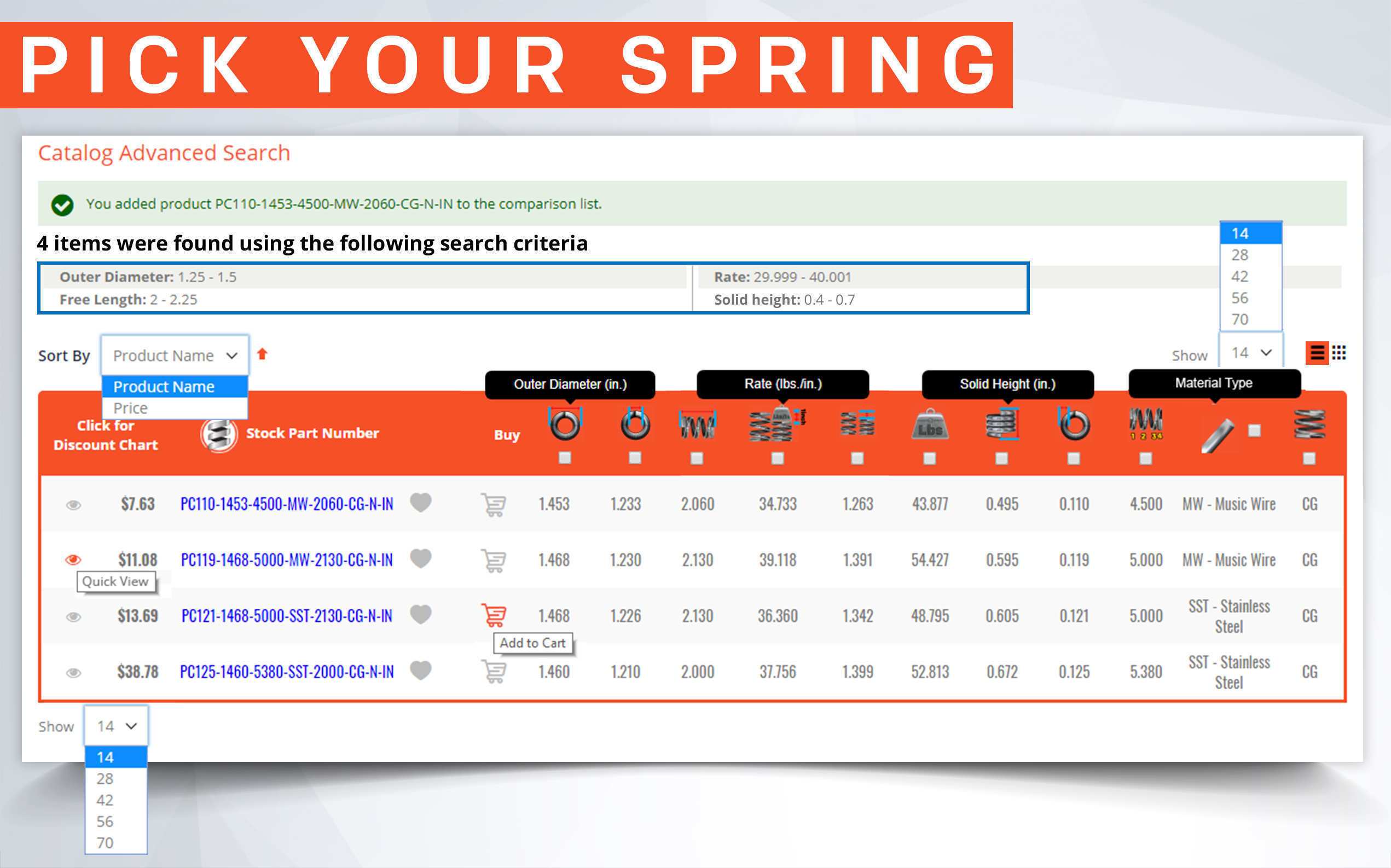

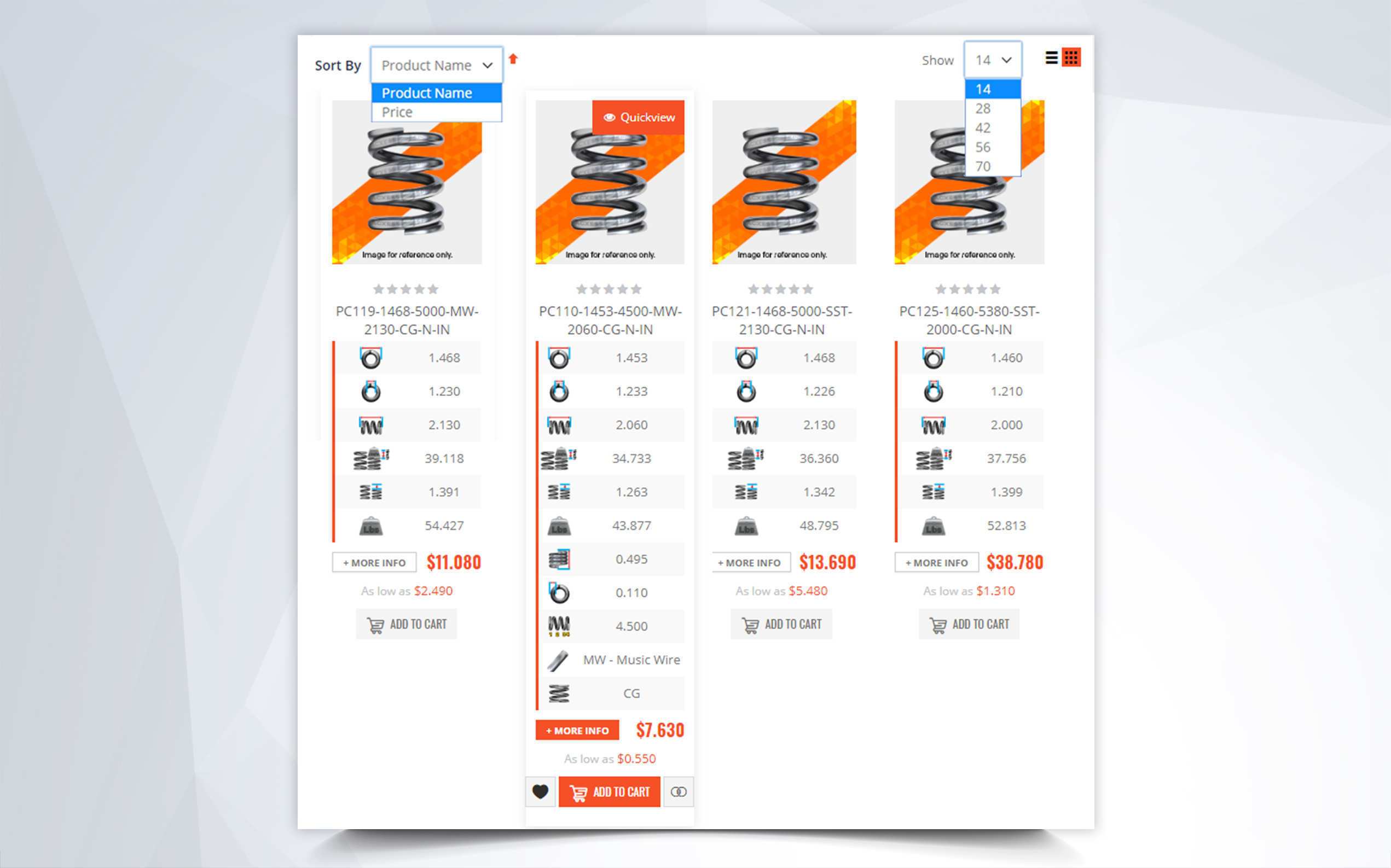

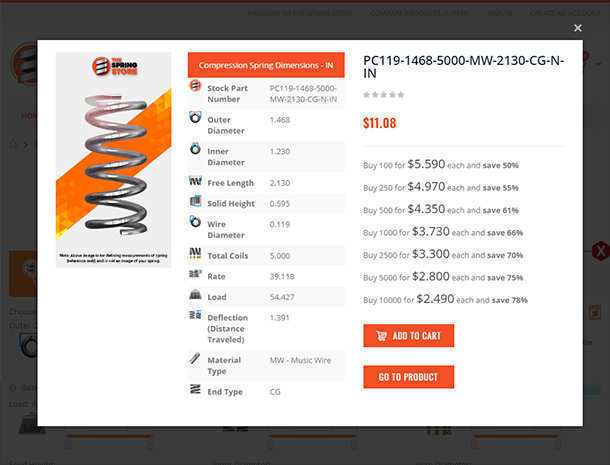

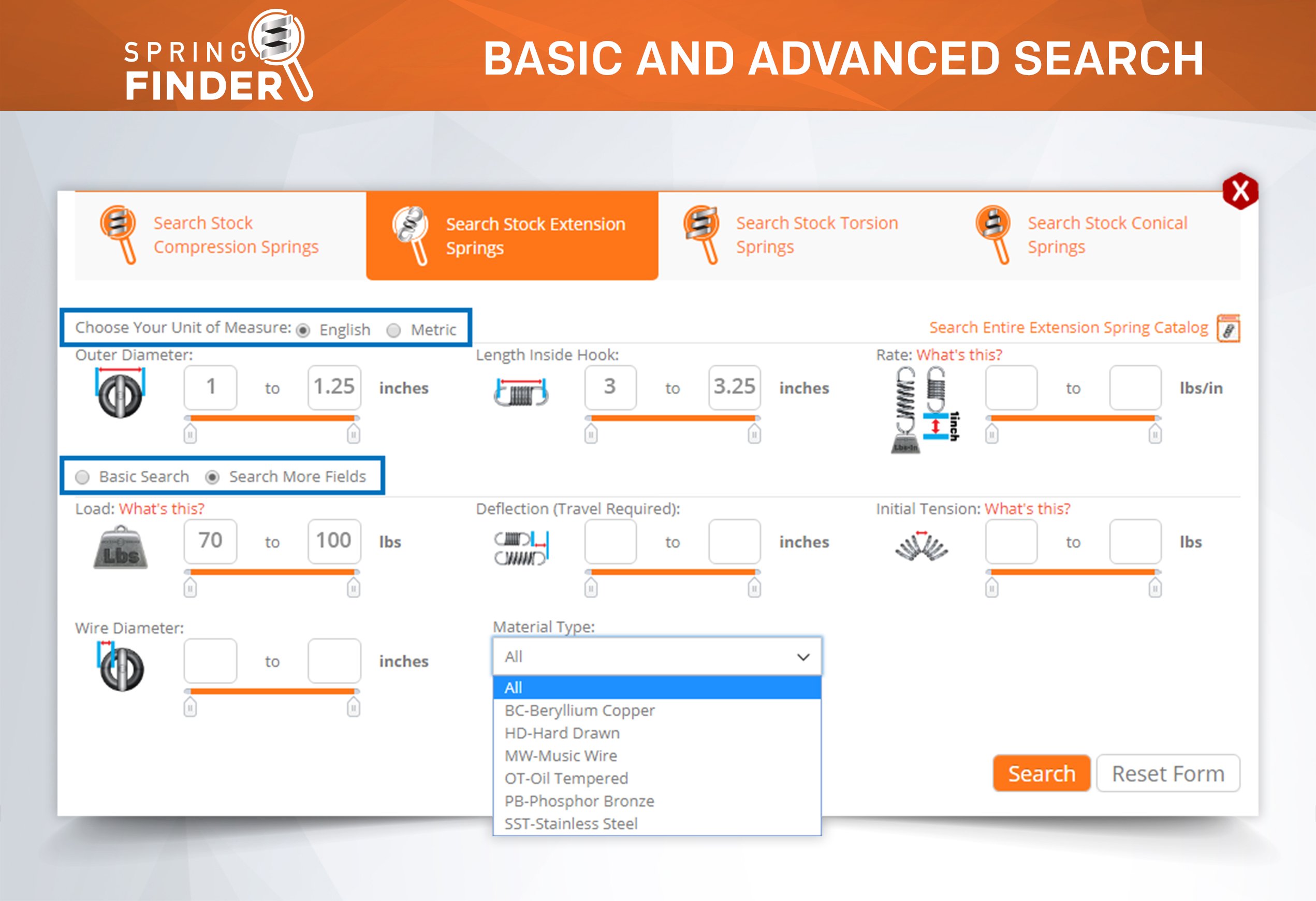

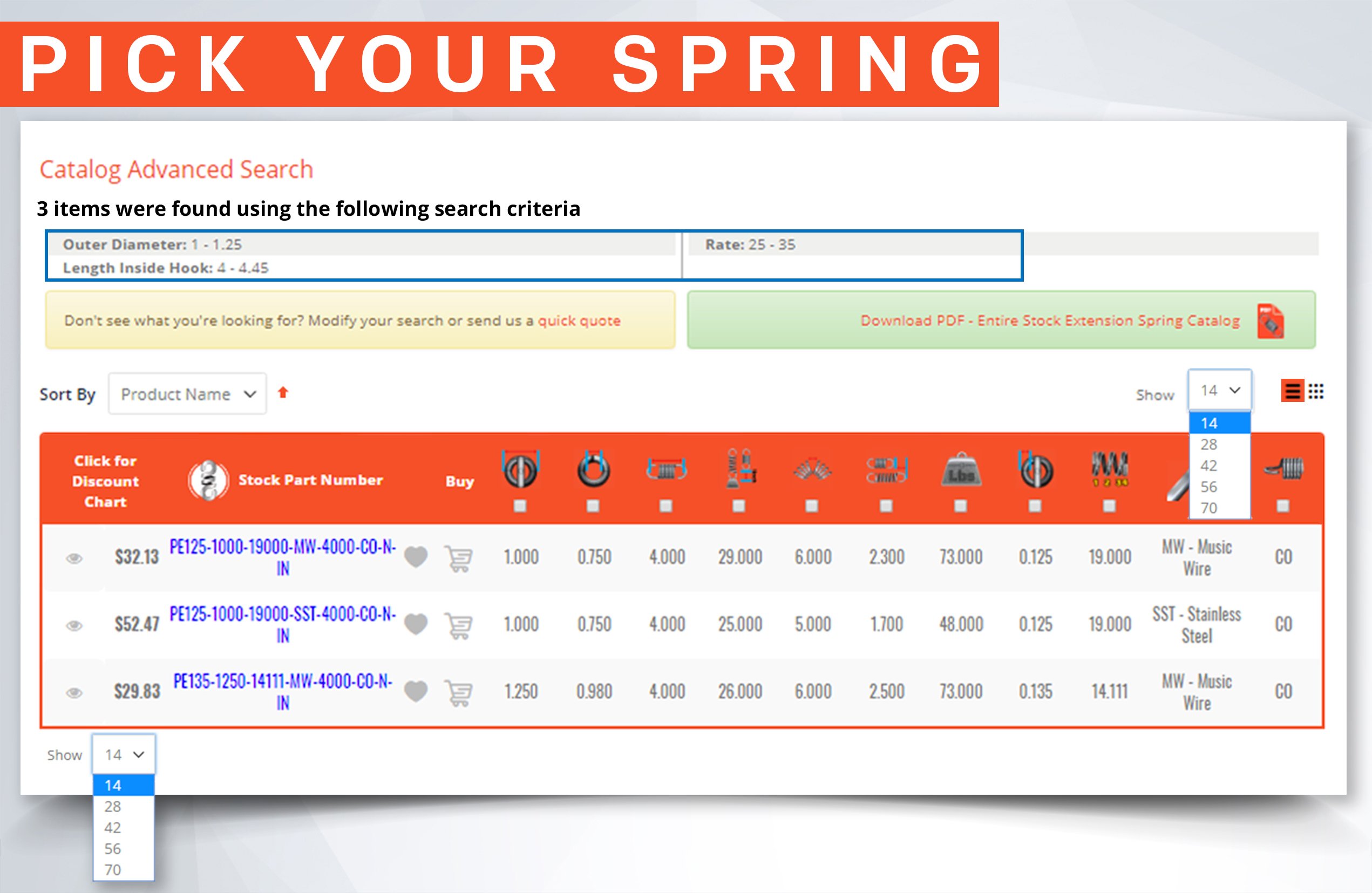

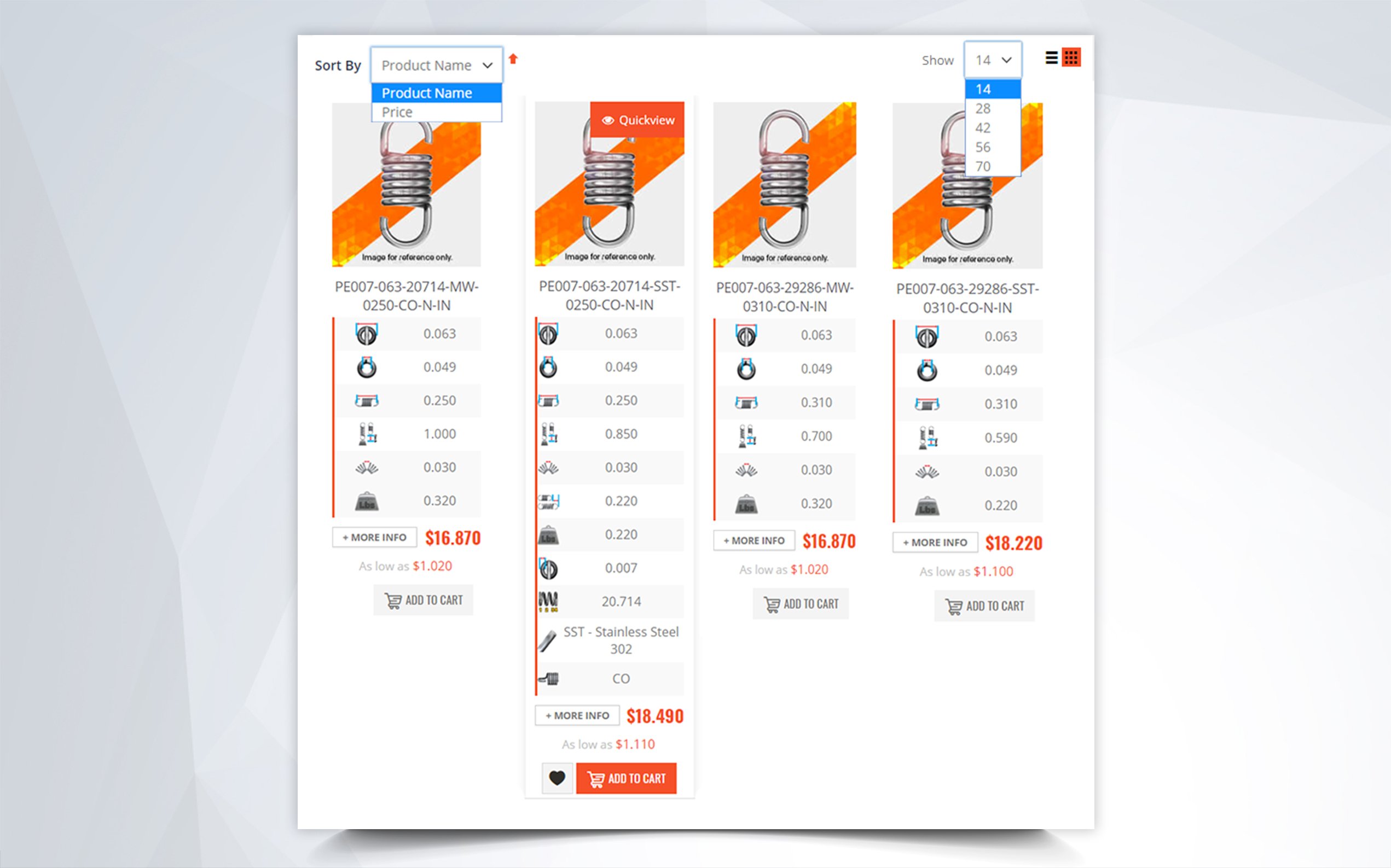

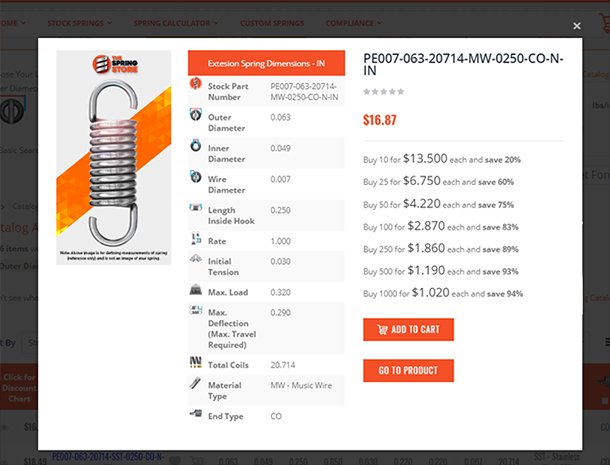

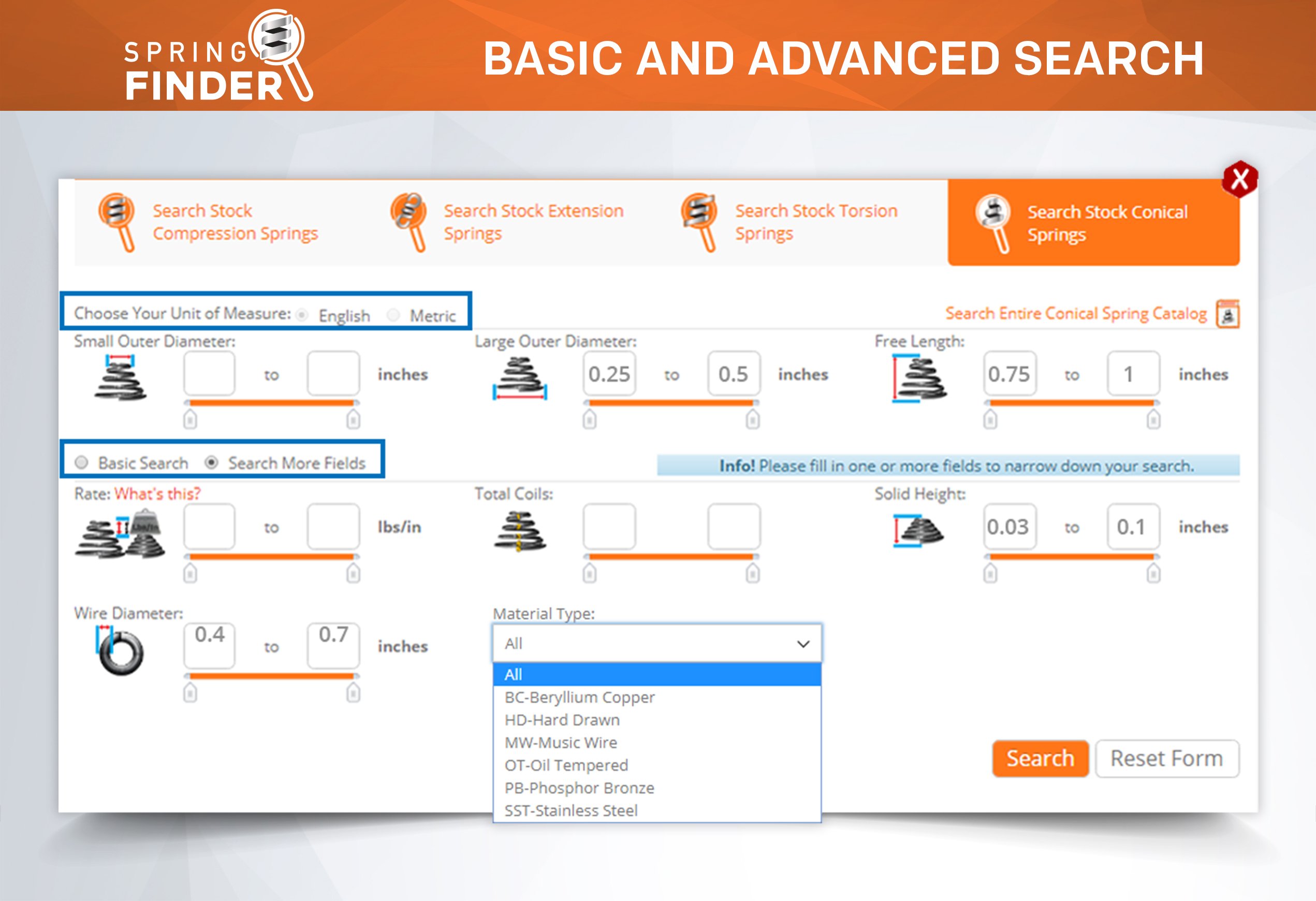

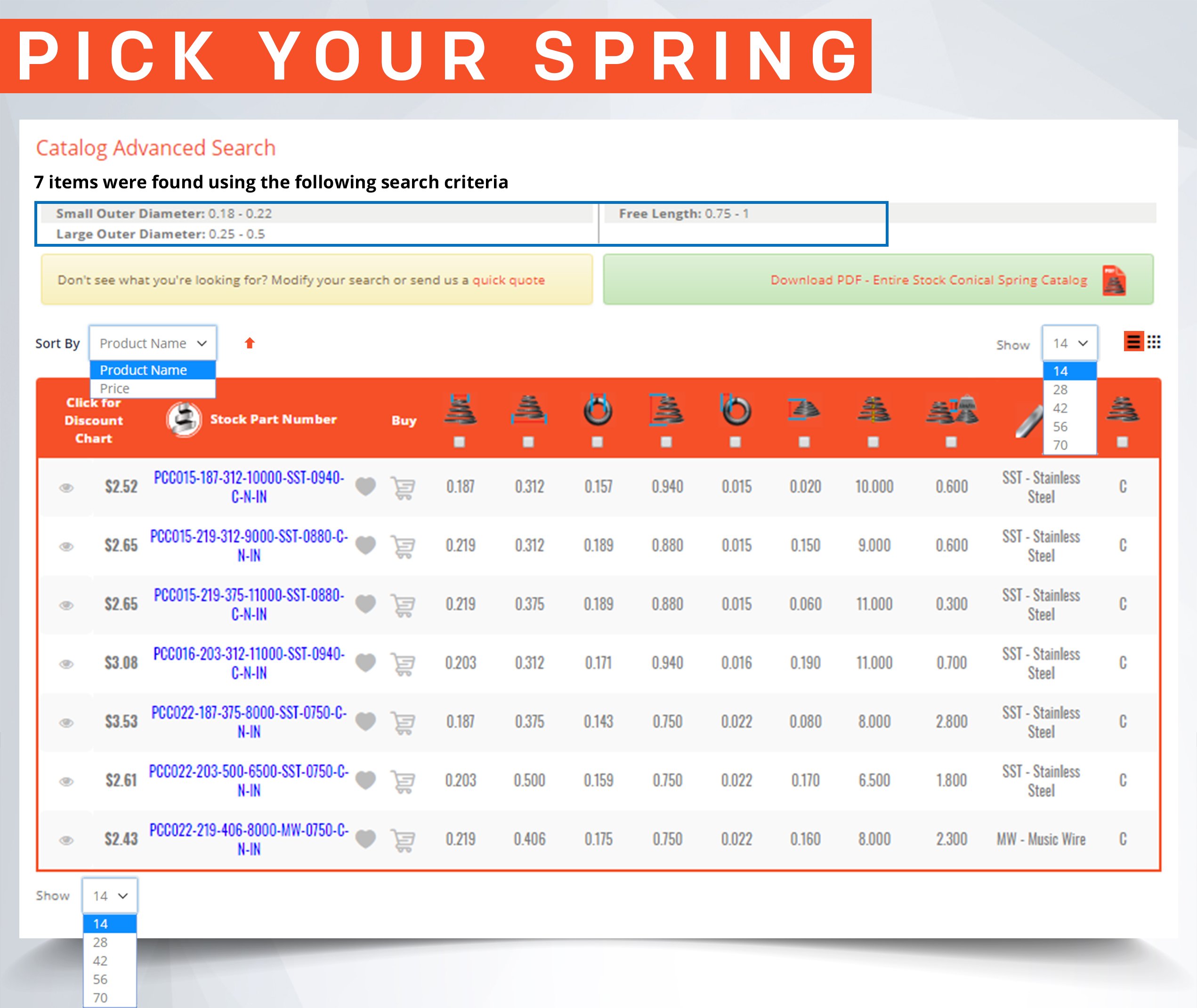

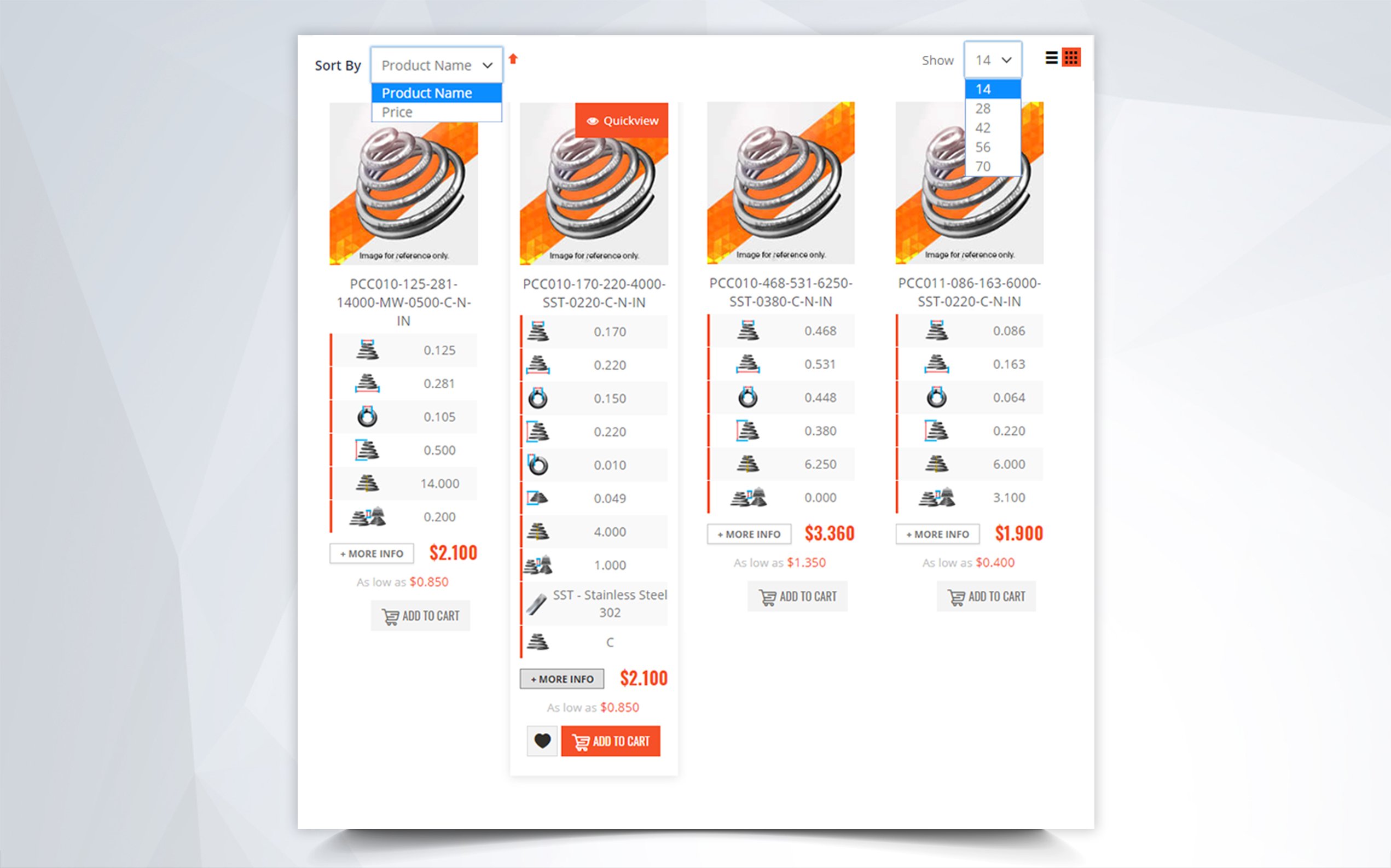

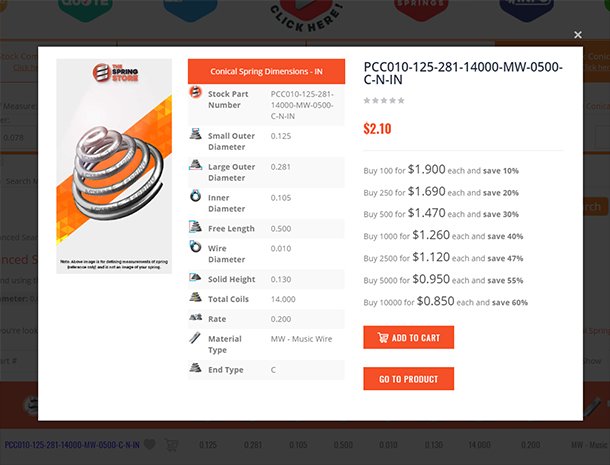

What to Consider When Looking for a Stock Extension Spring

We carry tension springs in stock with machine hooks and cross over hooks, you can conduct a spring finder search based on the dimensions and then look at the page result to verify what kind of hook the extension spring has. If it says CO it means Crossover hook, if it states MH it means machine hook. However, if you are looking for an extension spring without hooks and would like assistance with this please contact us directly at: (951) 276-2777 we are always happy to help.