How to Prevent a Spring From Buckling

What is buckling or bending in a spring?

Buckling or bending happens in compression springs during deflection due to the instability caused by a high slenderness ratio. As it is compressed, the lack of stability causes the coils to tremble and shift. This can cause the load to create pressure on the shifted coils and plaster them, damaging the spring.

Spring Slenderness Ratio

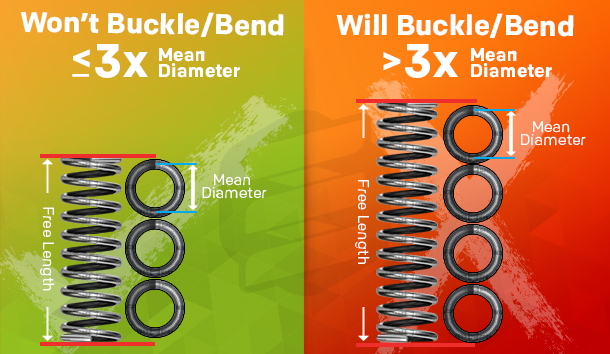

There is a simple concept to determine whether a spring will buckle or bend, it is called the slenderness ratio. The spring slenderness ratio is the proportion of the spring’s mean diameter to its length. If a spring’s mean diameter is more than 3 times its length, it will tend to buckle.

It isn't uncommon for a spring to have a free length greater than 3 times its outer diameter. That is why it is important to mention that there are different ways to deal with a bending or buckling issue. When creating a custom spring, you can make different adjustments to the design. When dealing with stock springs, you can make other adjustments to the placement of the spring.

How to Prevent a Spring From Buckling

In order to prevent a spring from buckling you can take the following measures:

Custom Springs

When designing a spring, you can change the slenderness ratio directly by taking the following measures:

- Increase the outer diameter.

- Reducing the free length.

- Add coils.

Stock Springs

When buying stock springs that have a longer free length, buckling may be an issue unless you take the following measures:

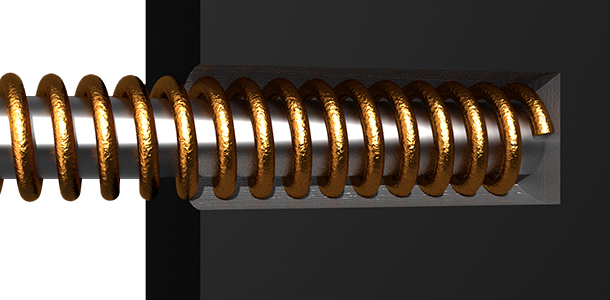

- Add a rod in the middle of your compression spring.

- Place your spring in a tube so it doesn't bend or buckle.

Doing the above will help your spring stay in place and avoid it from coming off your installation. However, there may still be slight friction with the walls of the shaft or hole, but it can be minimal and much easier to deal with.