Light Torsion Springs

Definition: Torsional springs which are either light in weight due to their small or average size, or have dimensions which make it a light spring in terms of torque.

A light torsion spring is a spring that might have a small or average wire diameter paired with an outer diameter that corresponds to a spring index no smaller than a 7 to 1 spring index. This means that the coils aren’t wound too tight so it is under less stress.

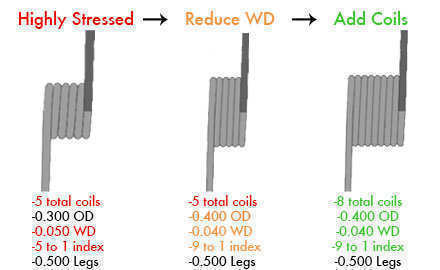

In the examples to the right you are able to see the difference between spring designs according to the proportion of its physical dimensions. One of the springs is under a lot of stress since it has a small index and little coils. This spring will not be as flexible to travel and it is also very strong. The next spring has an average index with an average amount of coils which now makes it a lighter spring. The last spring also has an average spring index but has less coils. This spring will be stronger than the previous spring but having an average index, it is under much less stress than the first spring so it will be able to give you more elasticity and more force. The second spring is a light torsion spring in rate while the last spring is a light compression spring in both rate and weight. This is because, since it has less coils, it requires less wire to be manufactured and less wire equals less weight. That is the case of the first torsion spring; It is under a lot of stress and it is also very strong but it is a lighter spring in weight since less wire is required to make a full coil. When picking a light torsion spring, it is merely a matter of perspective; whether you want a light compression spring in rate or in weight.

The force chart lets you know how you can make a torsion spring's rate per degree stronger or lighter. To make your spring stronger you may manipulate the spring index by making either the outer diameter smaller or the wire diameter larger, taking coils out, or creating more torque through more travel by altering the free position. To alter the free position angle of your torsion spring, you must basically take out part of the last coil; in doing so, you’re also making the spring stronger. Once you’ve taken a partial coil out, your spring will require more torque in order to reach your degrees of travel because it will have to undergo more travel. To make your torsion spring lighter, you can manipulate the tightness of its coils by either decreasing the outer diameter or decreasing the wire diameter. You may also add more coils or produce less torque through less travel by altering the torsion spring’s free position angle. In this case, you would add a fraction of a coil so that your spring has to undergo less torque in order to meet your required torqued position.

In terms of weight. A light torsional spring will be more effective on applications where weight plays a factor. As an example are aerodynamic applications. Having a light torsion spring will not be applying much weight on your application thus helping it work accordingly both in completing its task as a spring and still allowing it to be a light instrument. These springs will also be more economical in terms of manufacturing and shipping expenses. The manufacturing will be cheaper because less material will be needed to make the springs. The shipping will be cheaper because your package will weight much less.