Rotational Springs

Definition: Coil springs which exert a rotational force. Most commonly know as torsion or torsional springs.

Rotational springs get their name from the way they work because these springs deflect in a rotational manner; unlike compression and extension springs which deflect in a linear manner. The force and travel process is referred to as torque. The torque a rotational spring is able to eject is based on a spring rate per degree. The spring rate per degree specifies how many inch-pounds of torque you need for one degree of deflection. This is why they are installed to be used in objects that move in a circular motion.

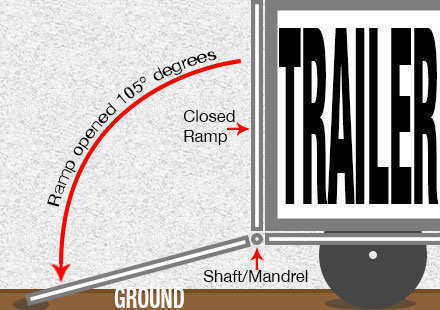

Rotational springs can be found in, lids, hinges, and trailer ramps; amongst other products. They either help these items rotate back to their original position (like the swinging doors in the saloons) or they are used as a weight assist like the ramps on trailers. The torque of these springs is measured in inch-pounds because not only is the force being applied taken into account but so is the weight of the door, hatch, lid, or ramp being applied. You are able to see an example of this in the diagram to the right. The ramp is measured and weighed and the values are multiplied together to determine the accurate torque that will be placed on the spring. These values are then divided by the degrees of deflection to get the required spring rate.

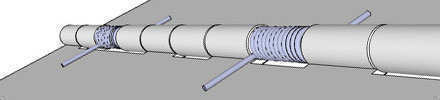

Because we're talking about a ramp here, you might need two or three rotational springs in order to reach your required torque and deflection. You're limited in space since the door hinges are small and the springs will be required to be able to carry this ramp so trying to pull it off with one spring may mean that you can meet the torque or torsion spring rate but the spring will be under a lot of stress meaning it won't be able to deflect much.

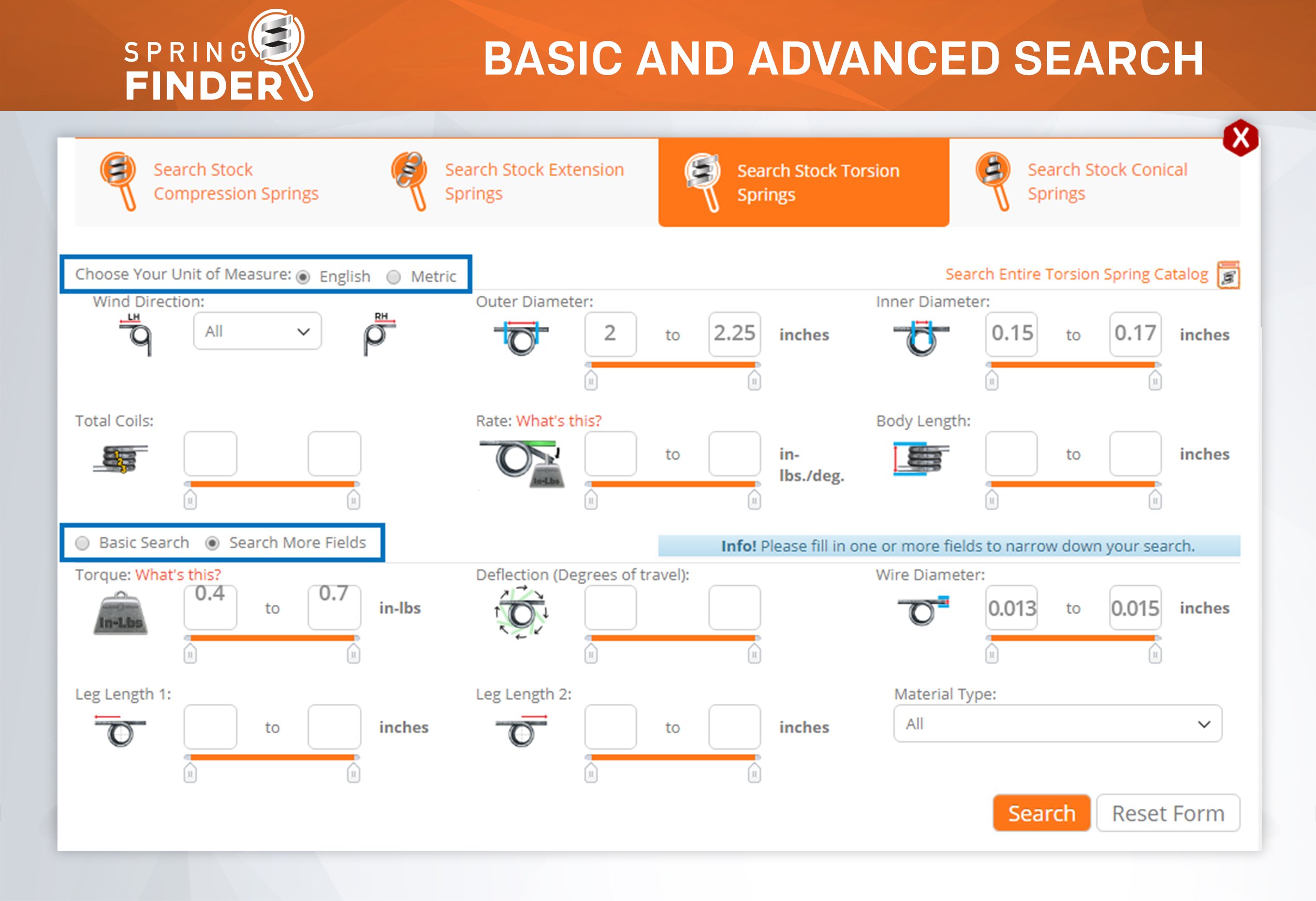

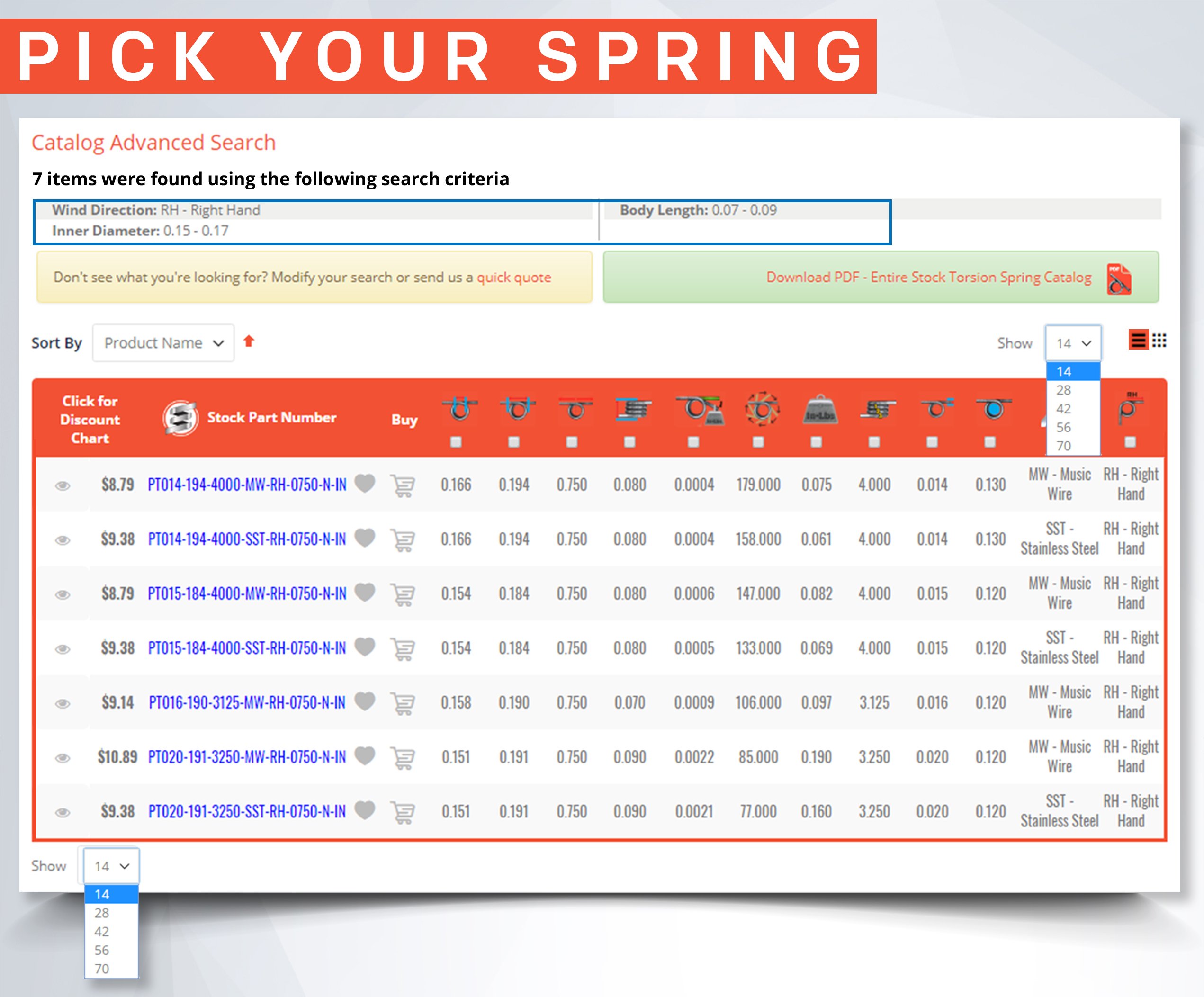

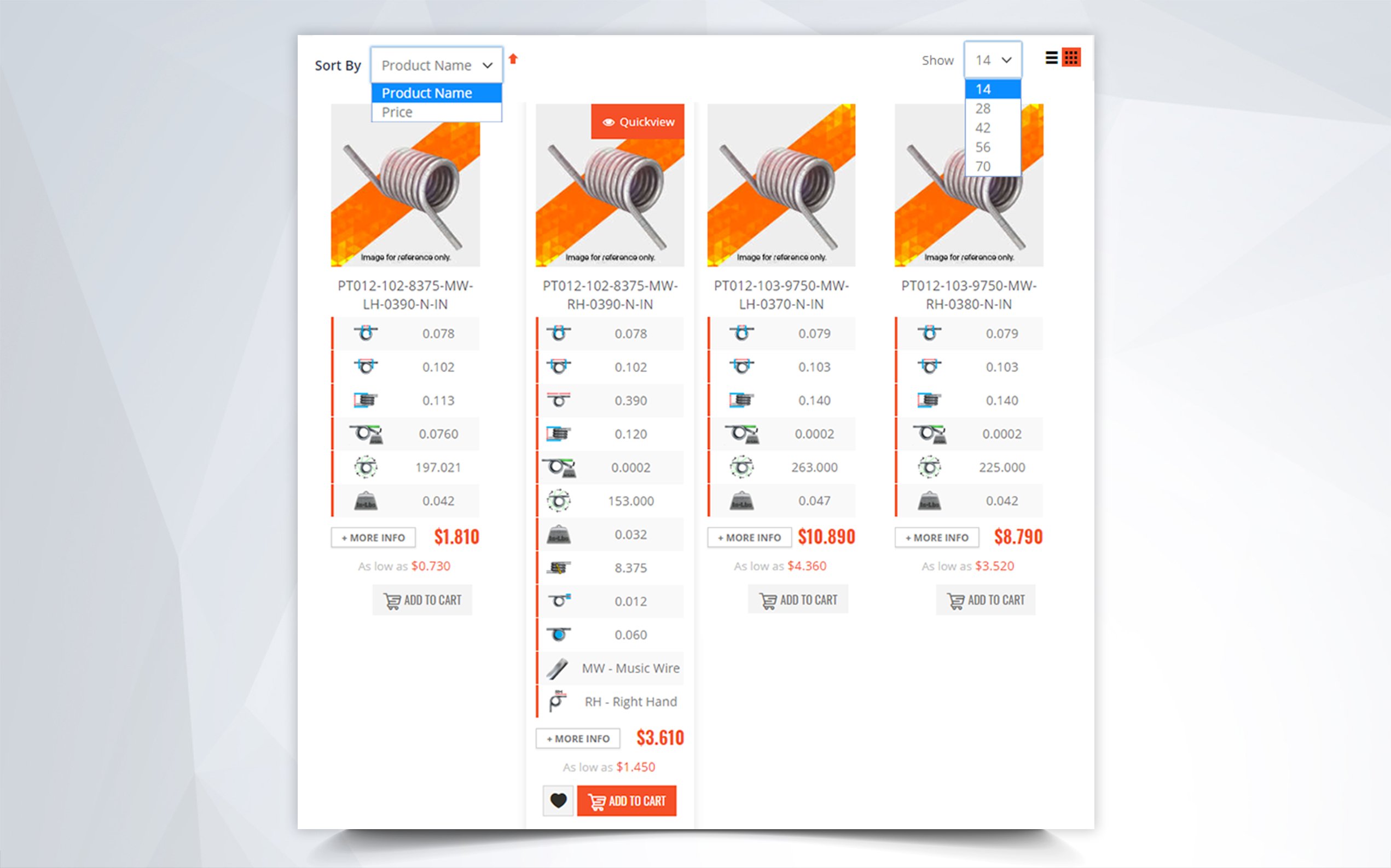

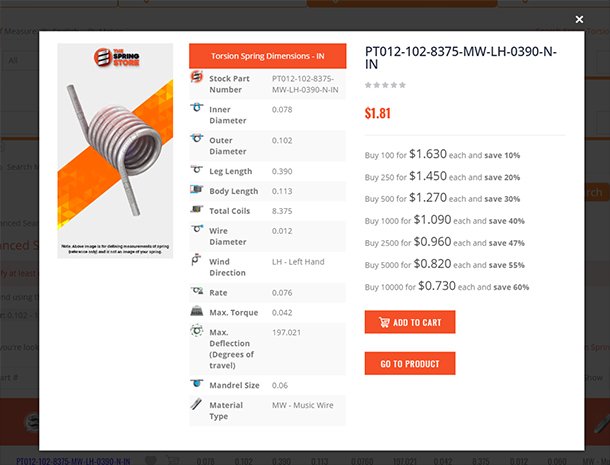

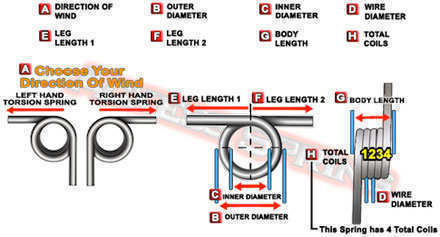

The measurements and specifications taken into account when designing a rotational spring are the following:

- Wire Diameter

- Outer Diameter

- Inner Diameter

- Body Length

- Total Coils

- Free Position Angle

- Leg Lengths

- Material Type

How to Measure a Rotational Spring

The wire diameter is basically the wire thickness. The outer and inner diameters can be calculated using this dimension. If you want to calculate the inner diameter, you subtract two wire diameters from the outer diameter. If you want to calculate outer diameter, you add two wire diameters to the inner diameter. This means that changing the wire diameter size can affect these measurements and, since most rotational springs are installed over shafts and their inner diameter contracts under torque, you must be very vigilant of this dimension and the tolerances you set on it.

There is also a limit on the space left for the spring's body. Body length is derived from the wire diameter and total coils. This means that, to stay on top of your body length limitations, you must look out for the wire diameter and total coils. It is calculated by adding one additional coil to the total coils and multiplying the product by the wire diameter.

The free position angle is also related to the total coils but this value depends only on the last coil or last portion of a coil. If the total coils is a whole number, your spring will have a free position angle of 0º or 360º. If it is a mixed number, meaning a whole number with a fraction or decimal, to calculate the free position angle you must multiply that fraction or the decimal by 360. In the case of the leg lengths, they have to be long enough to reach the components in charge of applying the torque on the spring.

Finally, the material type is to be chosen according to your spring's environmental requirements. If it is to tolerate high temperatures or corrosive environments, you might want to use one of our stainless steel options. If you need the spring to be non-magnetic, you can go for Stainless Steel 316 A316 or a copper derived material type. If the spring isn't required to withstand these harsh conditions, you may go with Music Wire ASTM A228 or Hard Drawn ASTM A227 which are the most economical material types. Plating options are also provided in zinc, black oxide, gold irridite, etc.