Standard Dimension Tolerances

Definition: The tolerance or acceptable range of a stock compression spring dimension due to the variation of tensile strength during its manufacturing phase.

Variation of tensile strength is a factor in any manufacturing operation but Acxess Spring has Quality Control Procedures in place to review all spring tolerances and dimensions before they are shipped from our warehouse. There are physical dimension tolerances which may apply to your spring’s outer diameter, inner diameter, wire diameter, or length. Below you will be provided with the dimension tolerance of a compression spring’s physical dimensions.

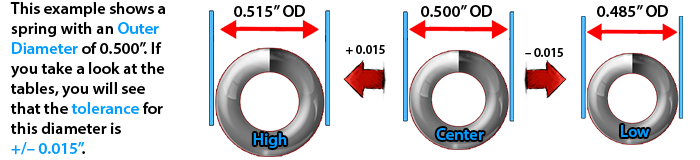

Inner and Outer Diameter Standard Tolerances:

0.025” to 0.050” ± 0.002”

0.051” to 0.100” ± 0.003”

0.101” to 0.250” ± 0.005”

0.251” to 0.500” ± 0.008”

0.501” to 0.850” ± 0.015”

0.851” to 1.125” ± 0.020”

1.126” to 1.250” ± 0.025”

1.251” to 1.480” ± 0.030”

1.481” to 1.750” ± 0.040”

1.751” to 2.000” ± 0.055”

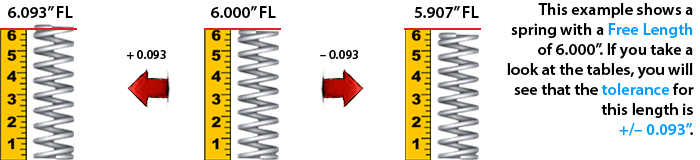

Free Length Standard Tolerances:

- 0.001” to 0.500” ± 0.015”

- 0.501” to 1.000” ± 0.025”

- 1.001” to 2.000” ± 0.050”

- 2.001” to 4.000” ± 0.100”

- 4.001” to 8.000” ± 0.200”

- 8.001” to 10.000” ± 0.300”

- 10.001” to 15.000” ± 0.400”

- 15.001” to 20.000” ± 0.500”

- 20.001” to 25.000” ± 0.650”

- 25.001” to 30.000” ± 0.800”

- 30.001” to 35.000” ± 1.000”

- 35.001” to 40.000” ± 1.200”

- 40.001” to 48.000” ± 1.375”

- 48.000” and up ± 1.500”

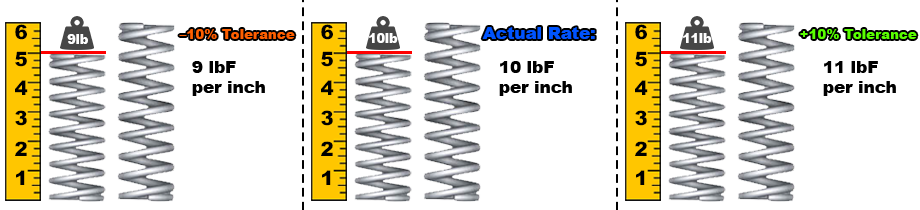

There is also a standard tolerance for a compression spring’s constant (rate per inch), loads, and travel. These tolerances vary depending on the amount. Please take a look at the tolerance charts provided below.