Standard Spring Rate Tolerance

Definition - The allowance of a permissible range in force per inch (or millimeter) applied to stock or standard springs for manufacturing purposes.

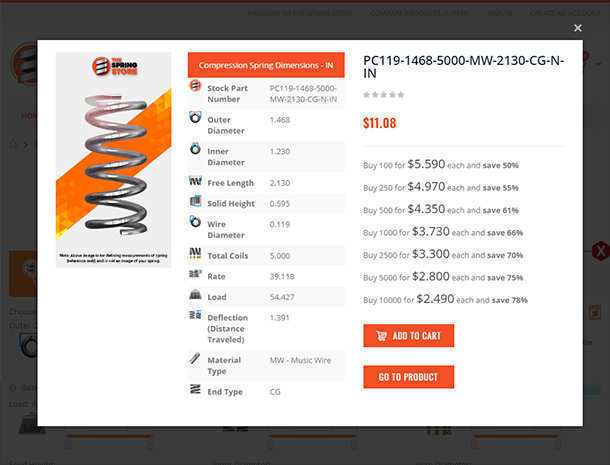

The tolerance for standard spring rate used in the industry is of plus or minus ten percent (+/– 10%). This means that if you find a standard spring that says to have a spring rate of 5 pounds of force, it may really be from 4.5 pounds of force to 5.5 pounds of force due to the tolerance applied. The smaller your spring rate, the smaller the range of tolerance that will affect your standard spring and the bigger your spring rate, the larger the range of tolerance applied to your spring as shown in the following examples.

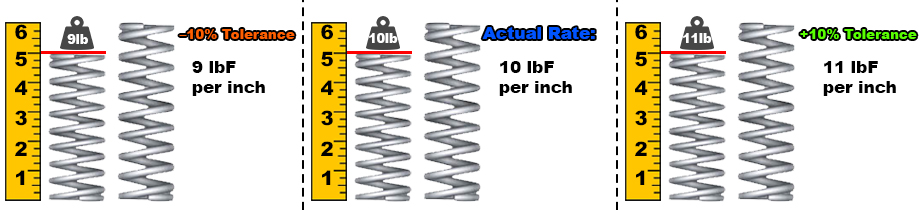

Example A.)

You find a standard spring which has a spring rate of 10 pounds of force per inch so once you calculate the tolerance, you will see that the actual rate of force per inch of this spring could range in between 9 pounds of force per inch and 11 pounds of force per inch.

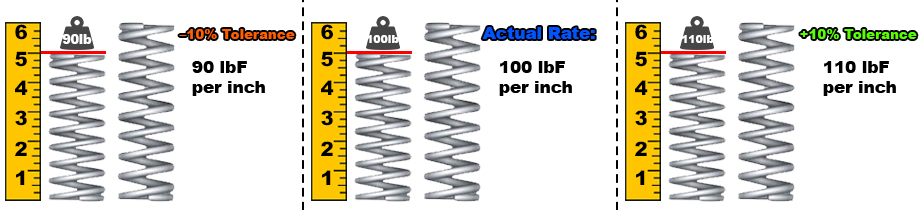

Example B.)

You find a standard spring which has a spring rate of 100 pounds of force per inch so once you calculate the tolerance, you will see that the actual rate of force per inch of this spring could range in between 90 and 110 pounds of force per inch.

Now that we have compared a small amount of rate with a large amount of rate, you can see the difference. On example a, the tolerance was of plus or minus 1 pound of force per inch while on example b the tolerance was plus or minus 10 pounds of force per inch.

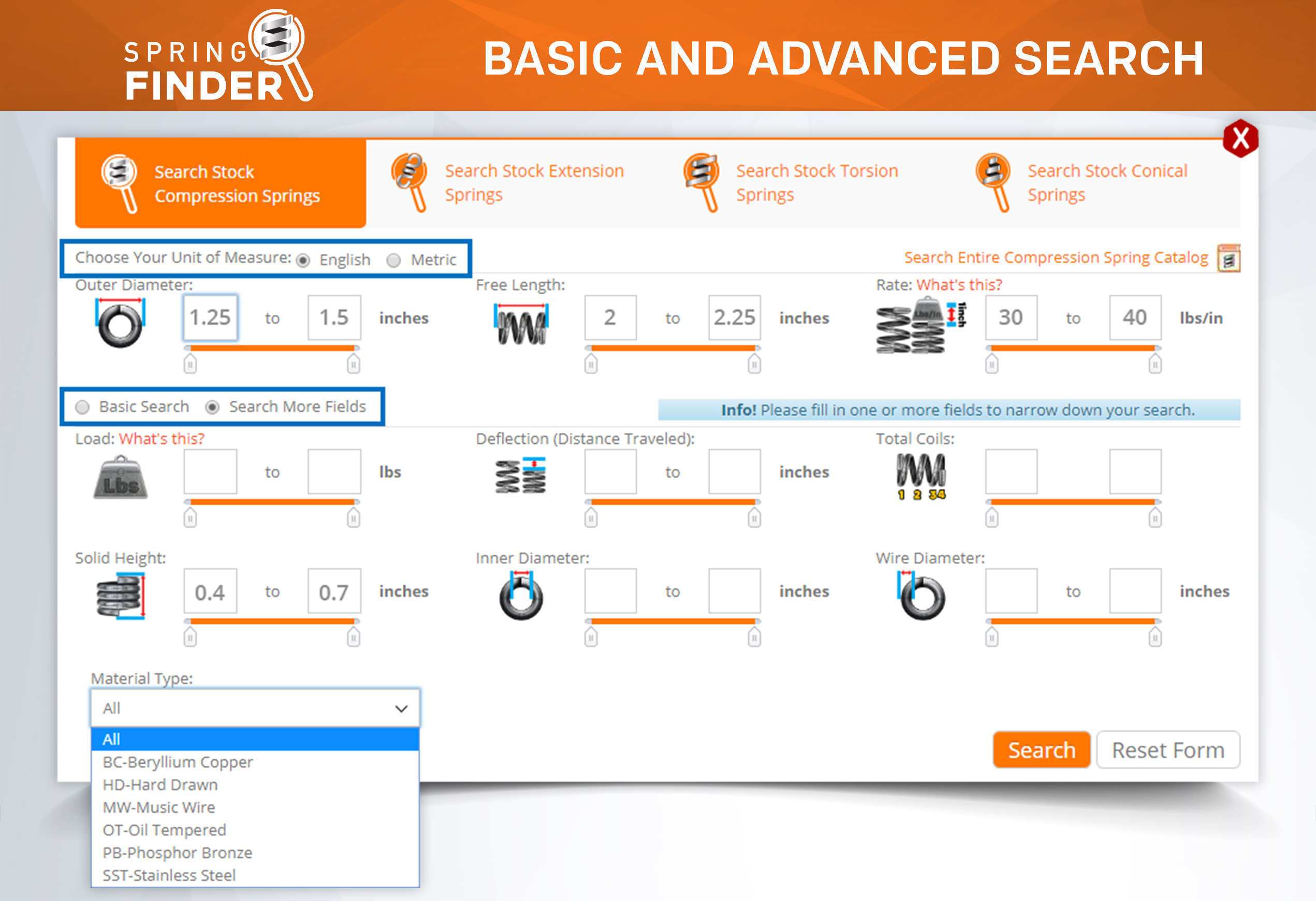

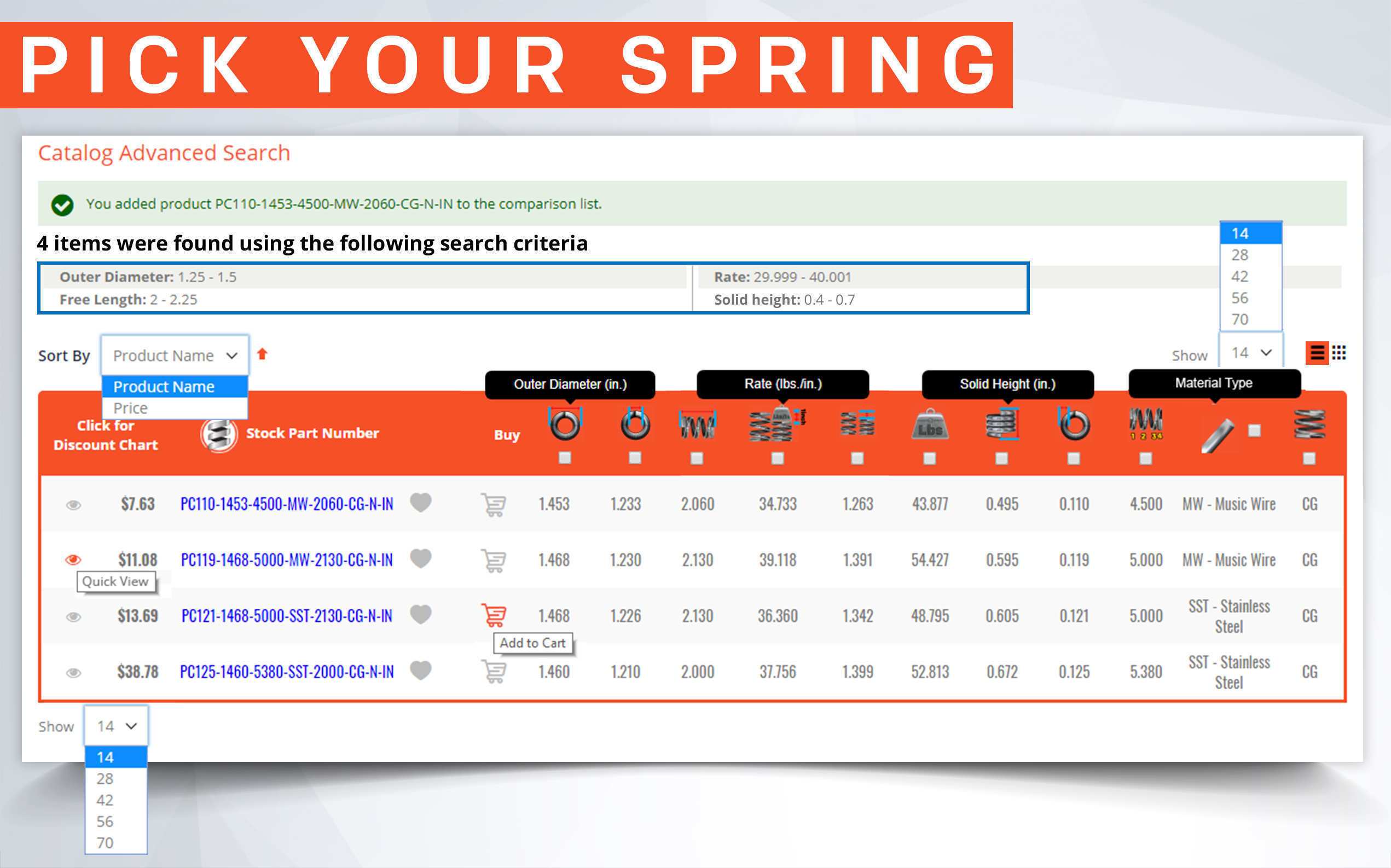

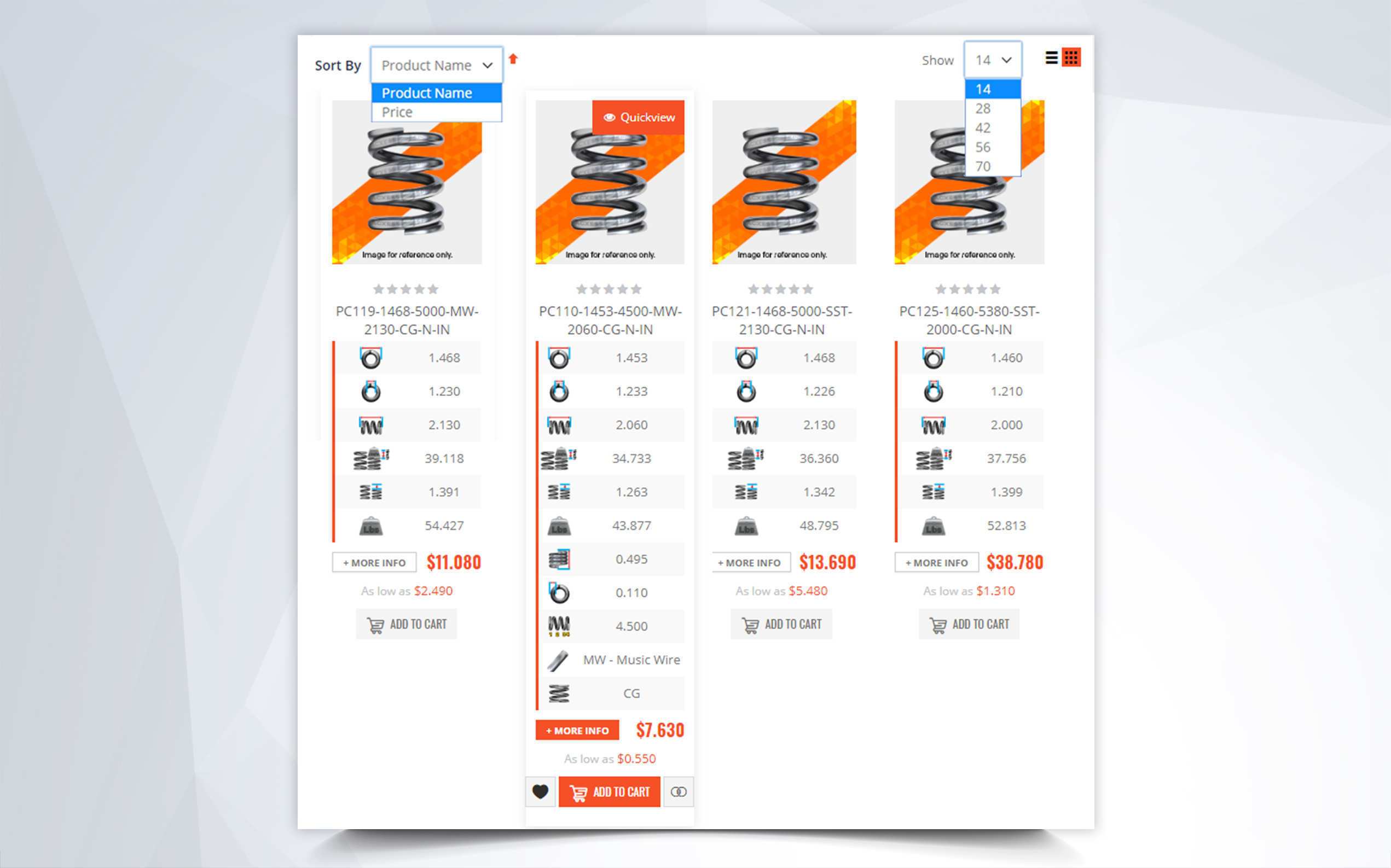

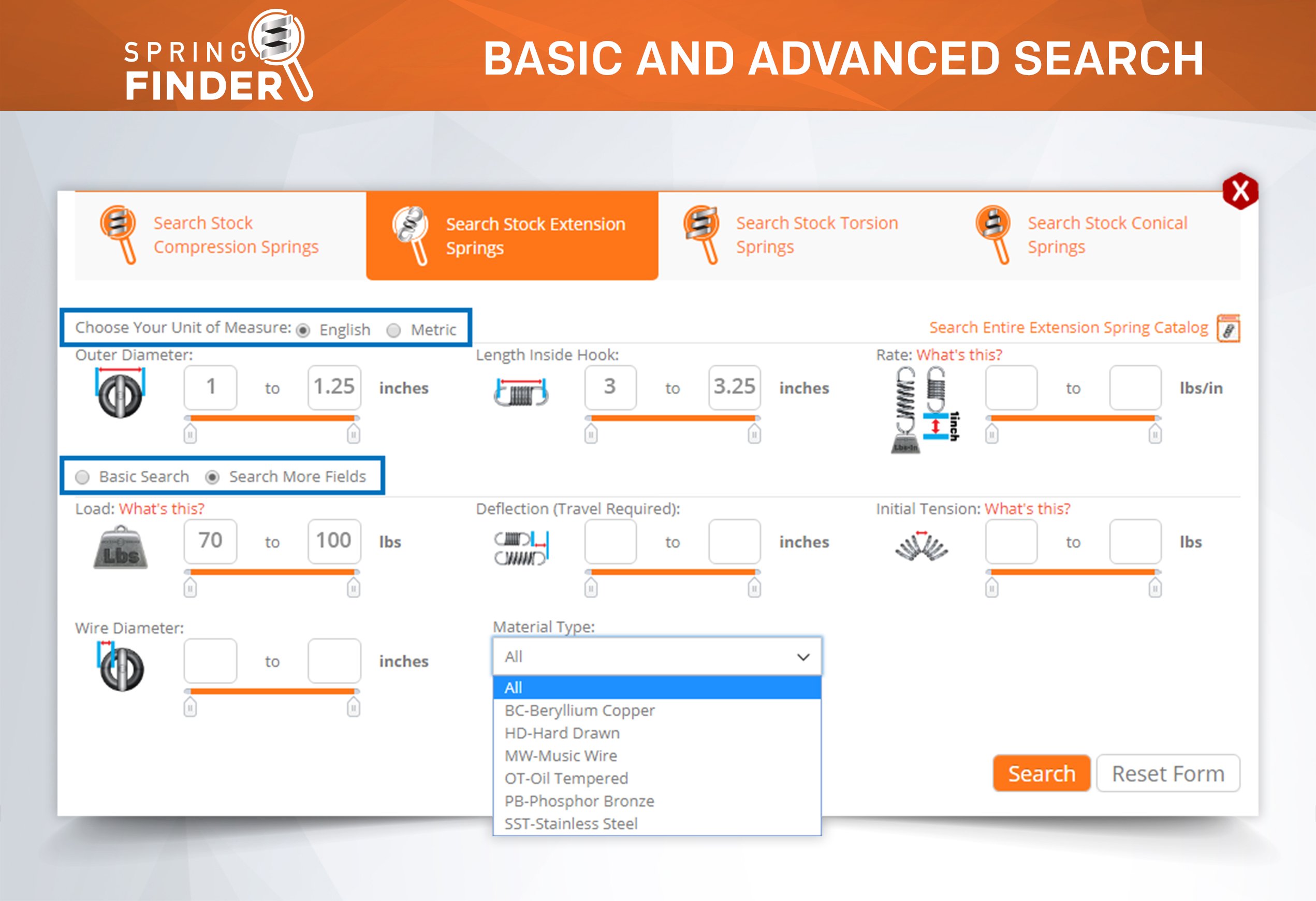

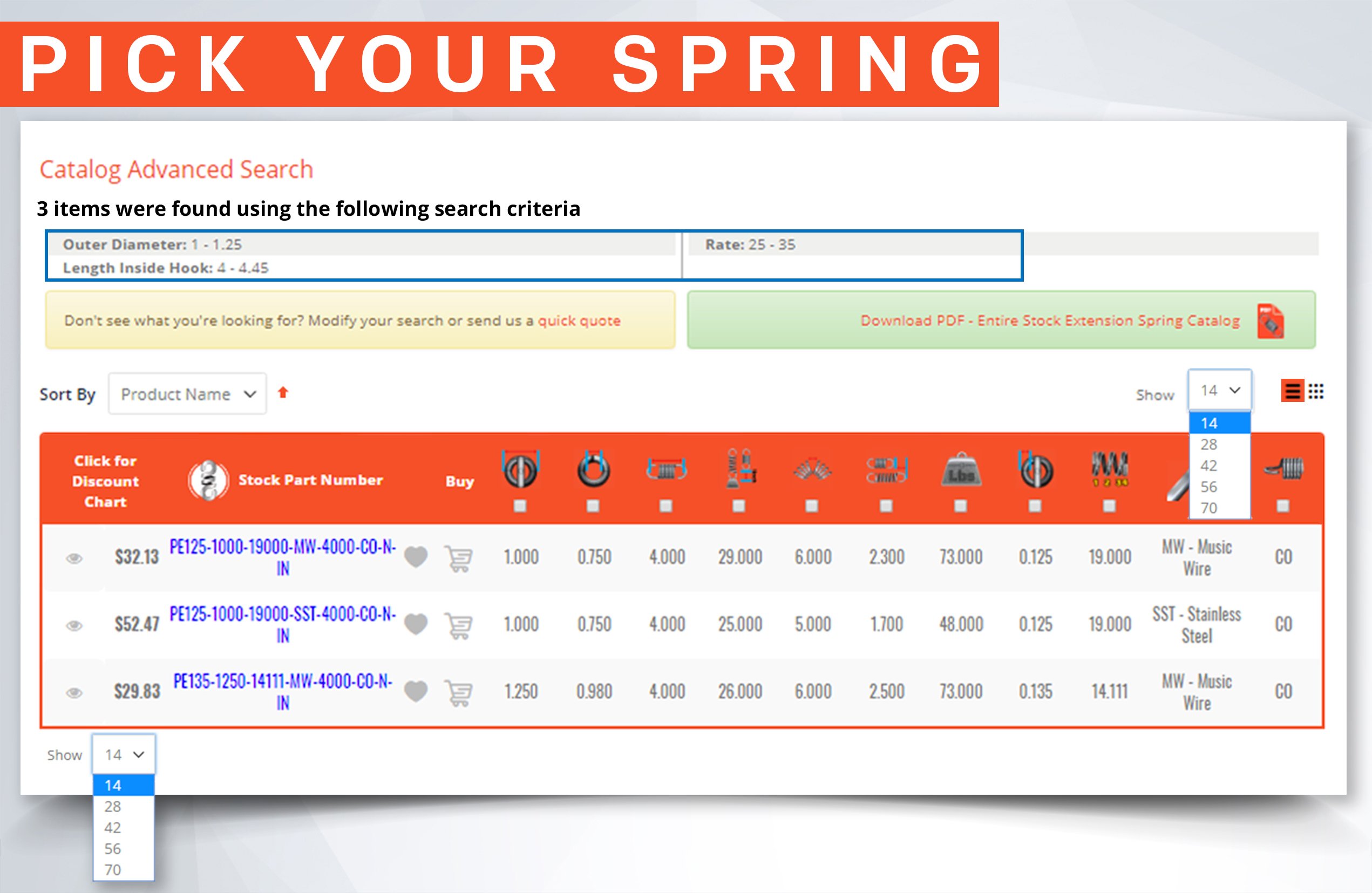

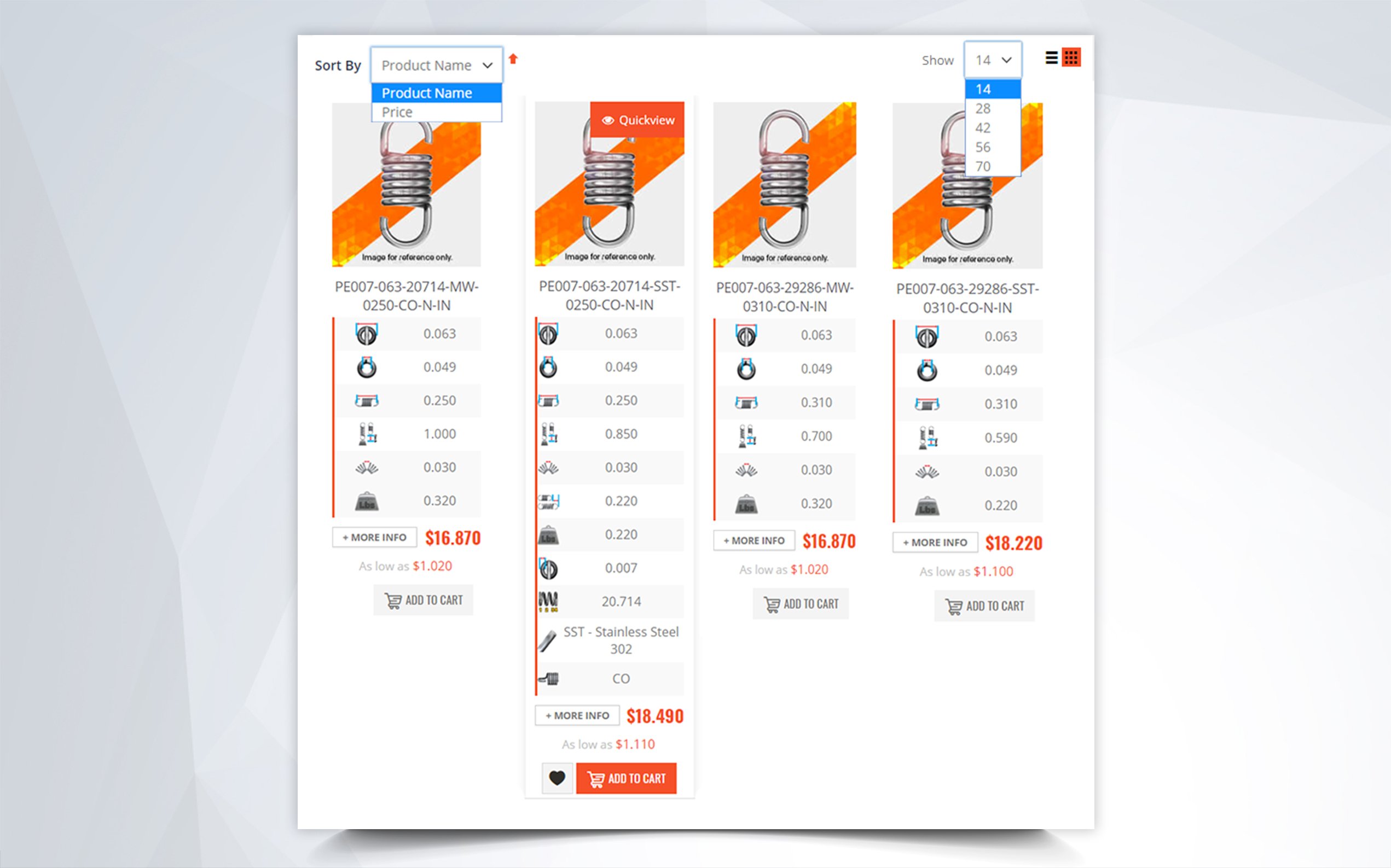

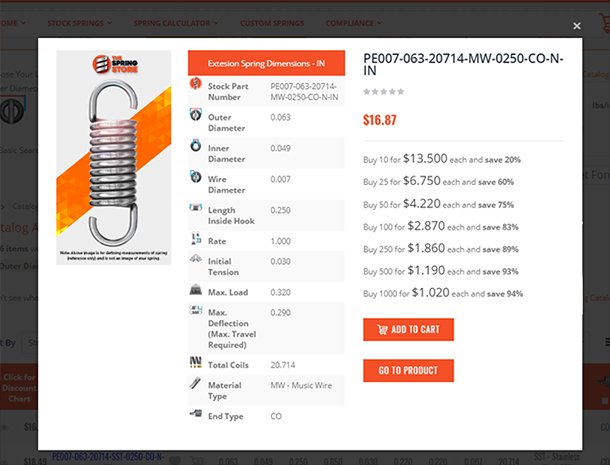

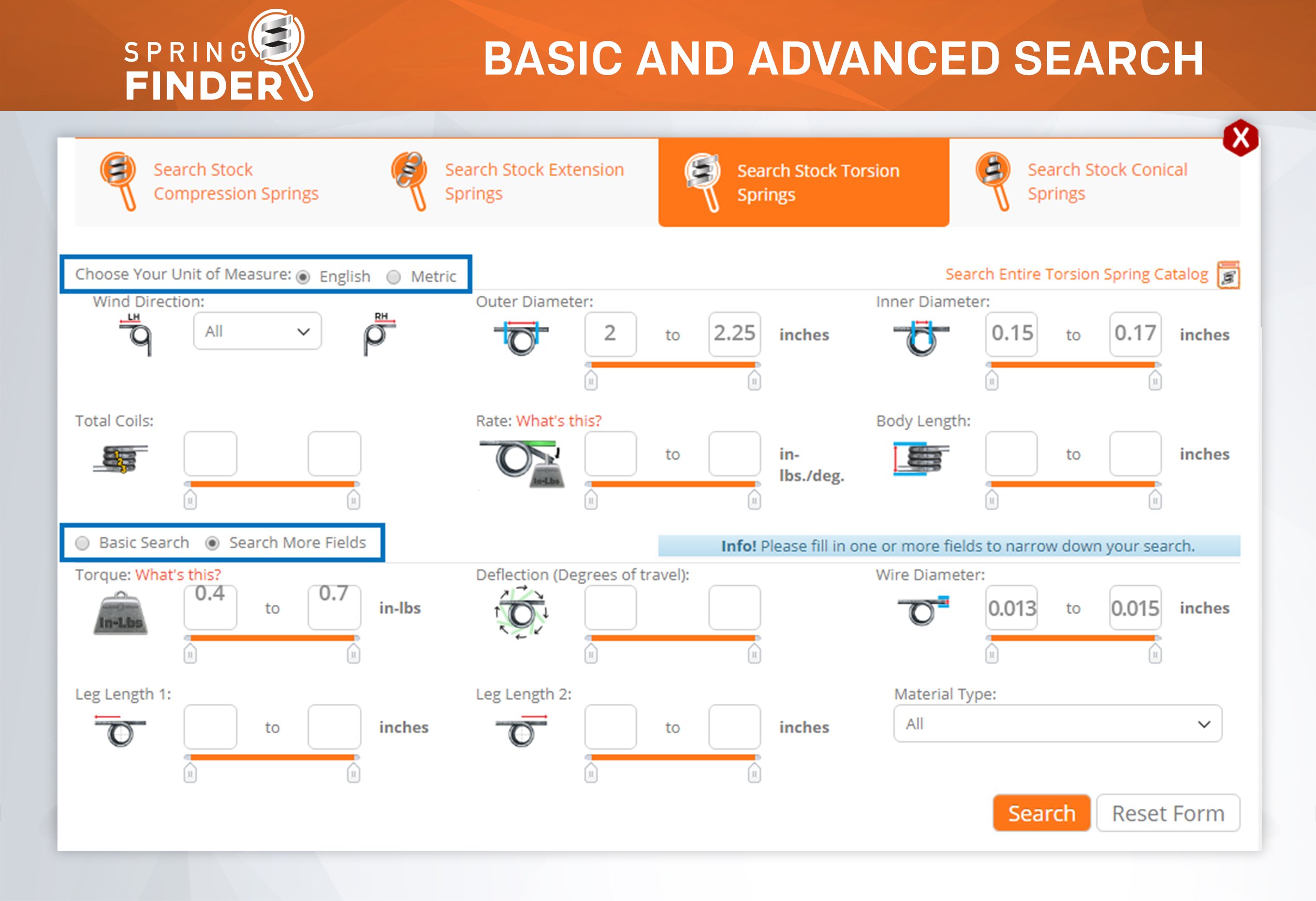

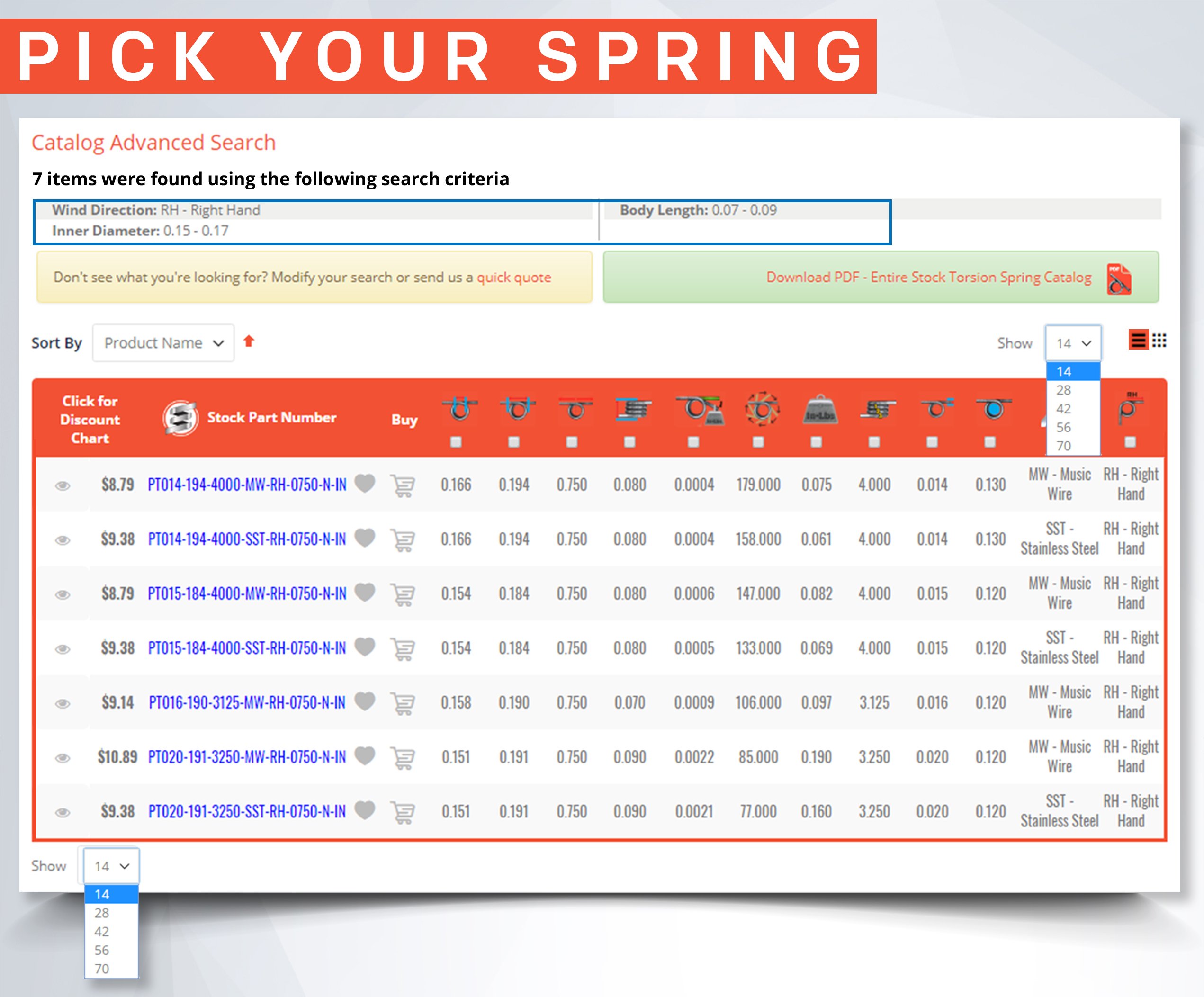

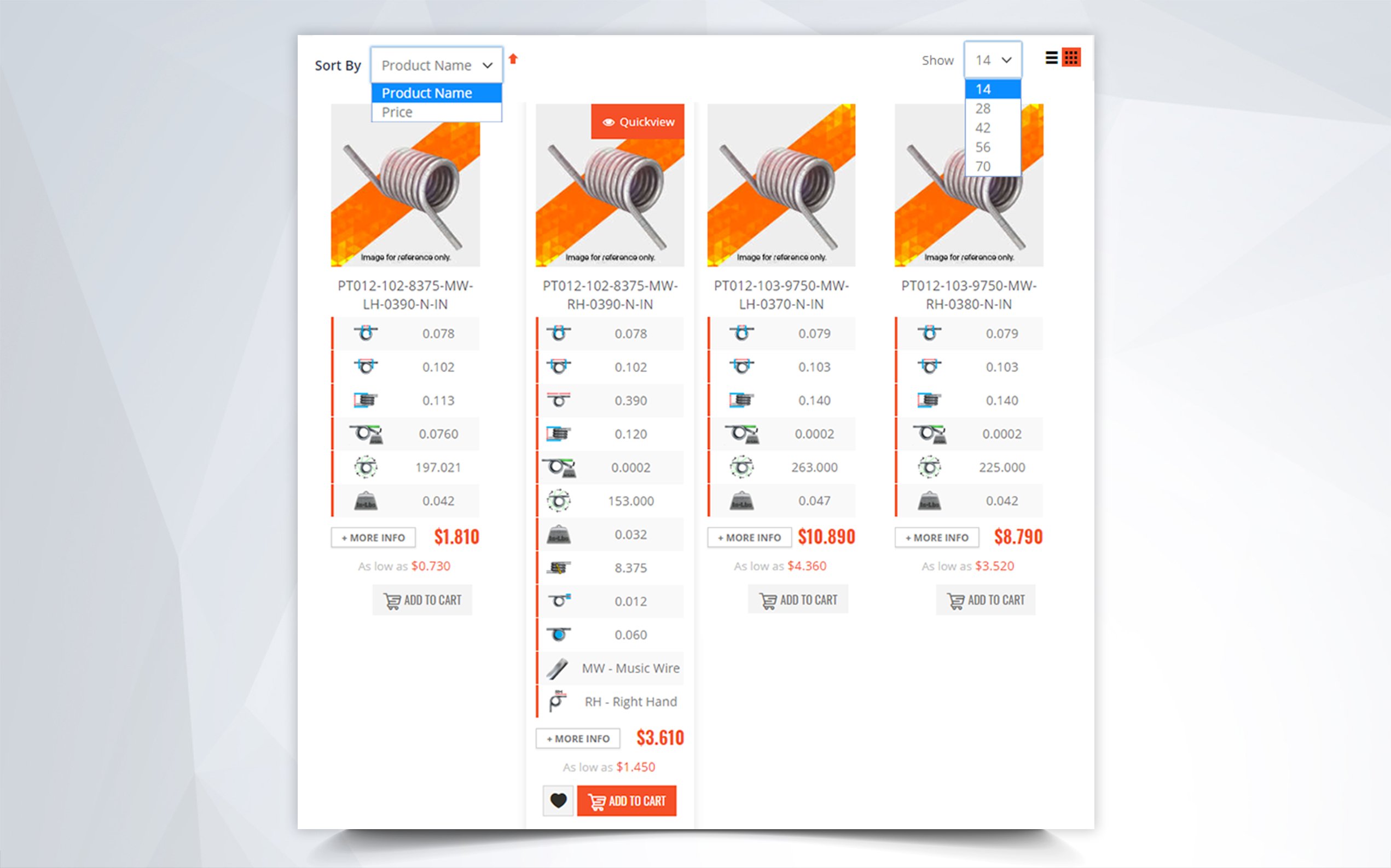

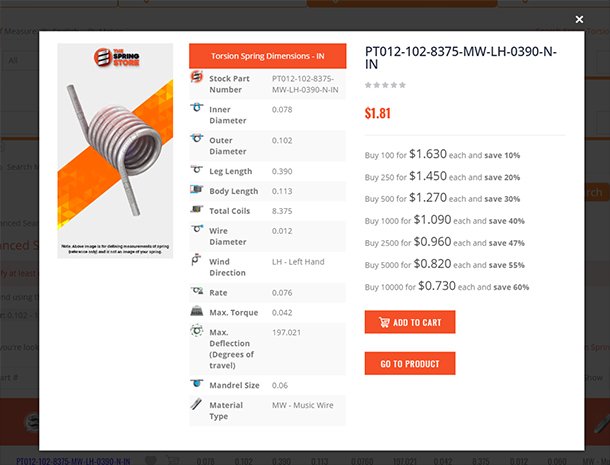

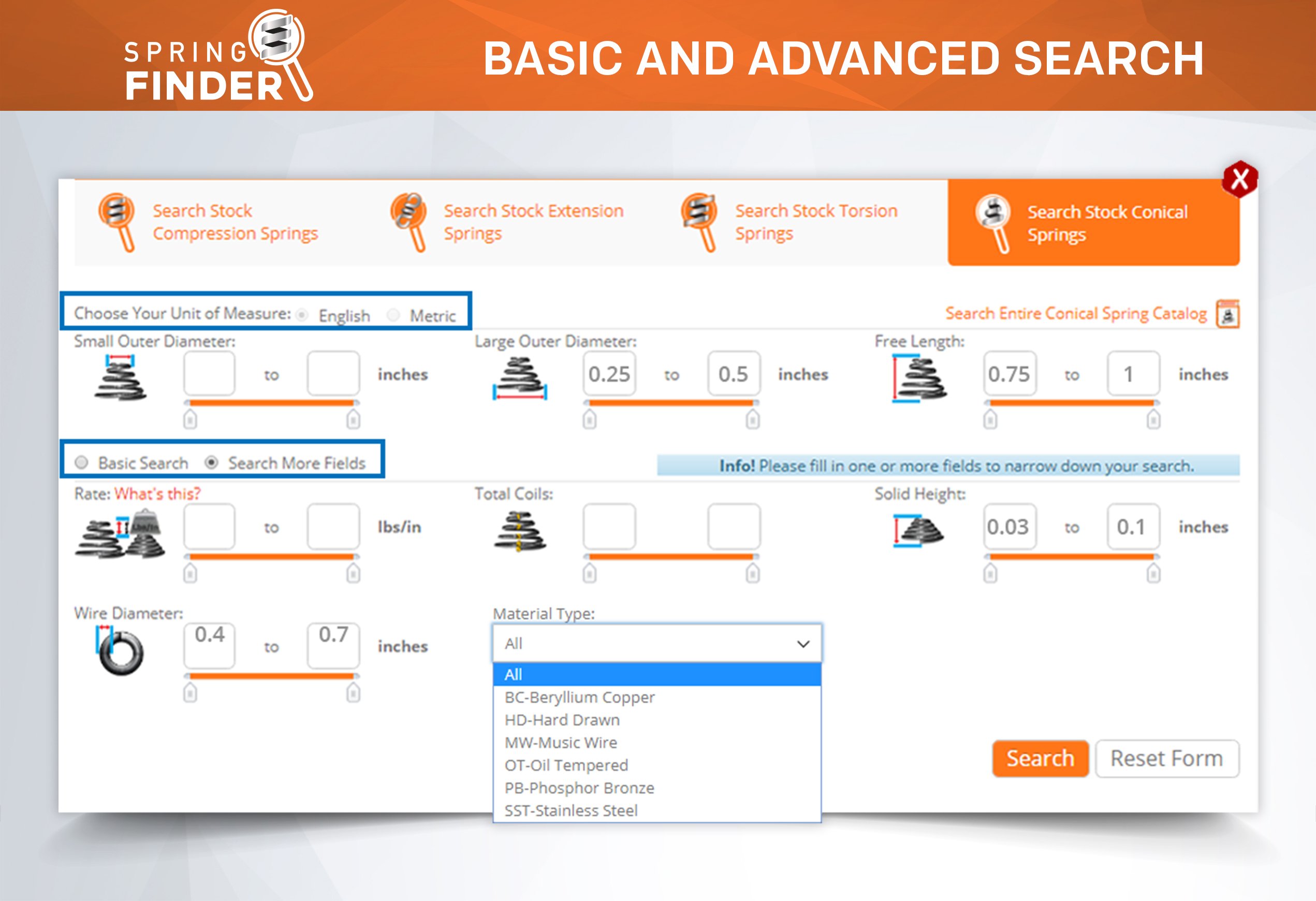

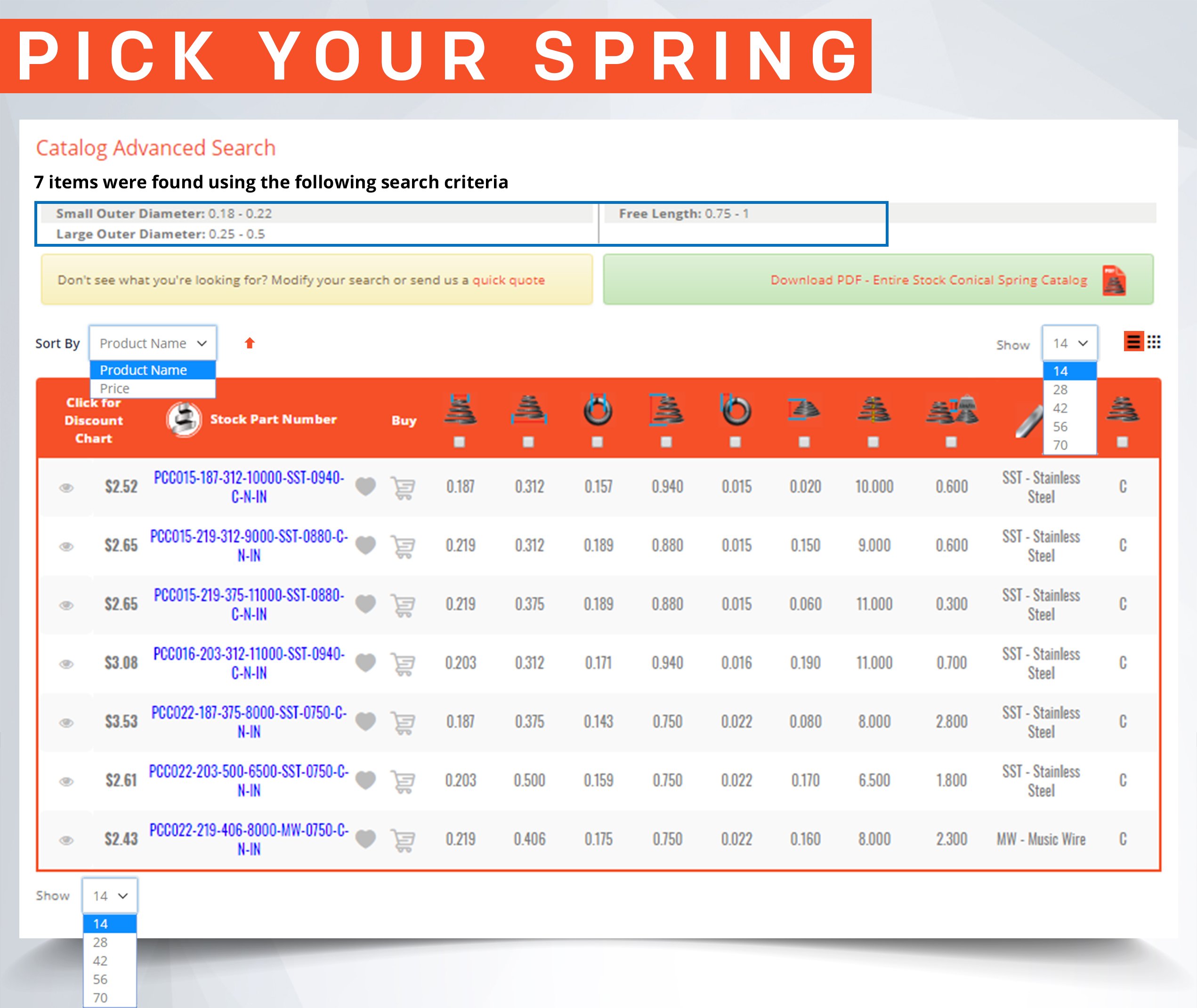

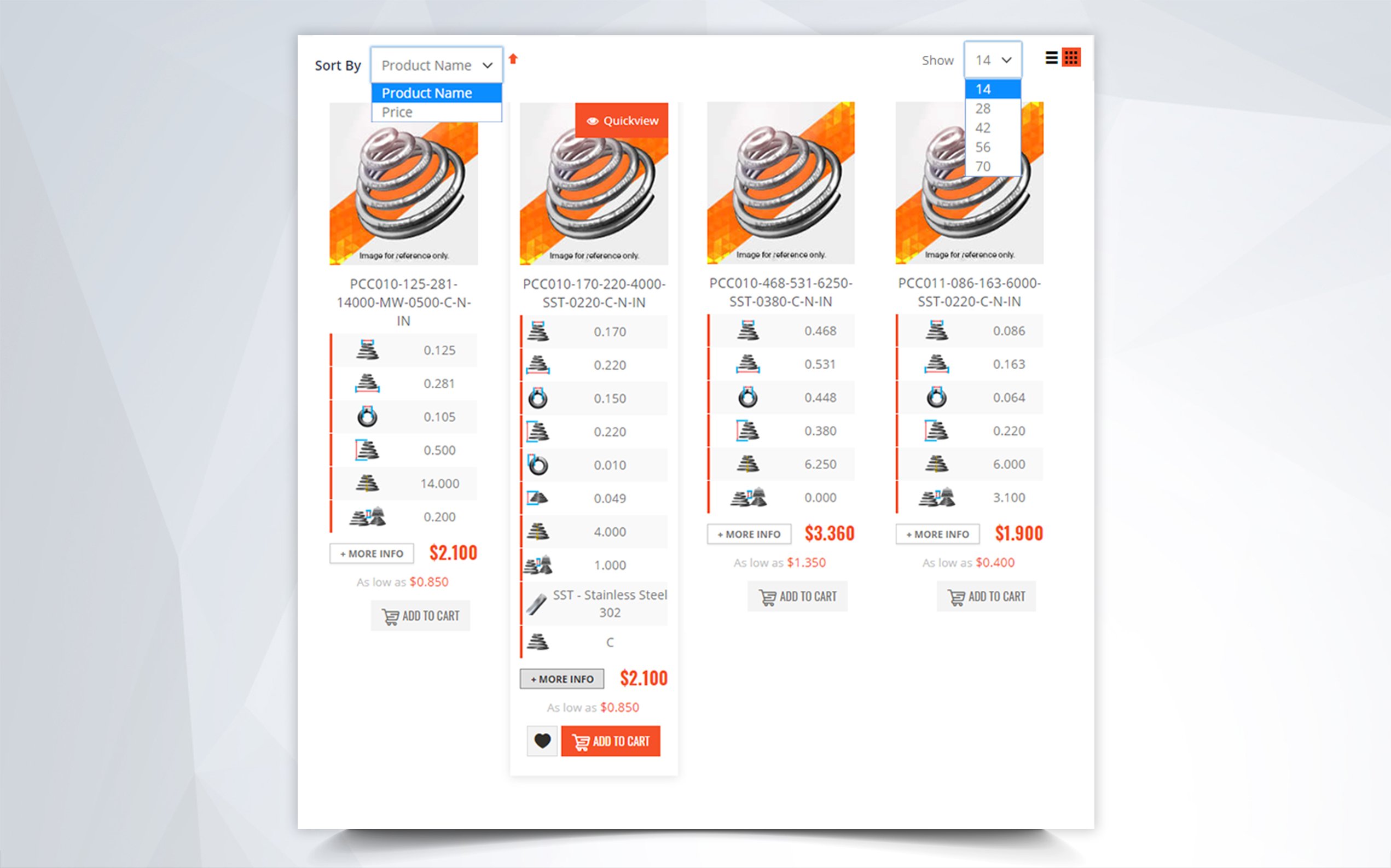

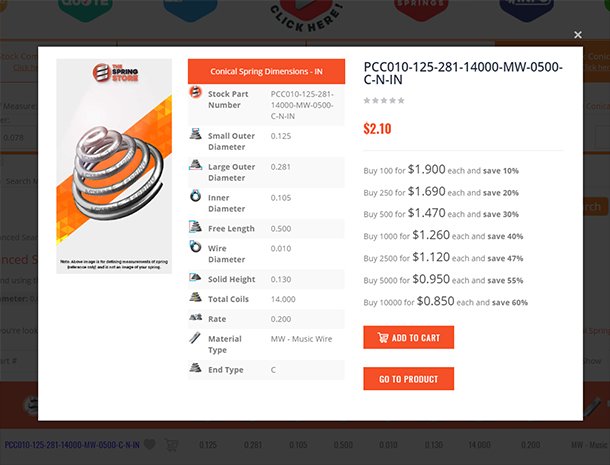

At StockSpringsCatalog.com by Acxess Spring we have a huge database with stock standard springs which vary in type and dimensions. Dimensions range from physical dimensions (like outer diameter and wire diameter) to their dimensions in force (like rate and maximum safe travel or load). Because these springs are standard and made in bulk to be kept in inventory, there are a few manufacturing tolerances that must be taken into note when it comes to your spring's dimensions as well as spring rate.