Extension Spring Calculator Instructions

Spring Creator is an advanced spring calculator tool. This spring calculator will calculate the force and elasticity when it comes to loads, rate and distance traveled. The following instructions will demonstrate how to use the Spring Creator tool as well as how its many features, like the availability of stock springs, that will benefit your testing and prototyping phase.

Step 1.) Choose Your Hook Type

-Machine Hooks:

Most economical and commonly used type of extension spring hooks. This type of hooks forms from the center of the spring.

-Cross Over Center Hooks:

Is also a common type of coil tension spring hook. It will give you 25% longer hook lengths than machine hooks thus giving you a full loop hook. They are manufactured by lifting the last coil and bending the end part of the wire to the center of your tension spring’s diameter therefore crossing the center.

-Side Hooks/Loops:

Side Hooks/Loops are similar to cross over hooks but are more economical since the extra labor of bending the coil to the center of the diameter is excluded. Side hooks/loops are formed from the side of the coil and not the center. These loops are a good choice if you need to place the hook on a side plate or a hole to the side where their is no room for the extension spring body and just the side hook/loop.

-Extended Hooks:

(Most expensive hook type) This type of hooks is required when your need your spring to have a shorter body length (less coils) making it beneficial to make the hook lengths longer. Extended hooks are also a good choice when you need a long hook to be able to get into hard to reach places or to place your hook in a hole or around a wall where their is no room for the spring body.

-No Hooks:

Extension springs with no hooks are used when the user decides that instead of using hooks, they will use a all thread or a threaded bolt on each end to thread into the extension springs inner diameter for more cycles of life and to avoid hook breakage. Using all thread or a threaded bolt to screw into the extension springs inner diameter on the spring ends (usually at least 3 turns on each end to secure the spring ends) will allow the user to use the “maximum safe travel” regardless of hook stress. Tension springs with no hooks are also used to manufacture the well known garter springs.

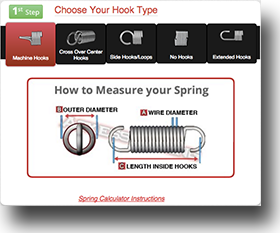

Step 2.) Enter Your Spring Dimensions

This is where you actually input your extension spring dimensions. The dimensions required are wire diameter, outer diameter, length inside hooks, and a material type. Once you have filled these in, you may click on “Calculate” and receive the results for your extension spring design.

To measure your spring’s length inside hooks please see the diagram “How to Measure Your Spring” or measure from inside hook to inside hook. You may also calculate this dimension by multiplying the wire diameter by two and subtracting the product from the overall spring length.

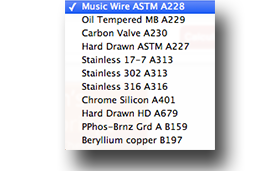

Our extension spring calculator also provides you with various types of material or wire types. Material types have different tensile strengths and some are specifically used for certain requirements such as environments with high temperatures or with a certain level of moisture. If your spring isn’t being placed in a harsh environment and you don’t need any special requirements, music wire is the best and most economical option. For more information regarding spring materials please visit our properties of common spring materials page: www.acxesspring.com/properties-of-common-spring-materials-spring-wires.html

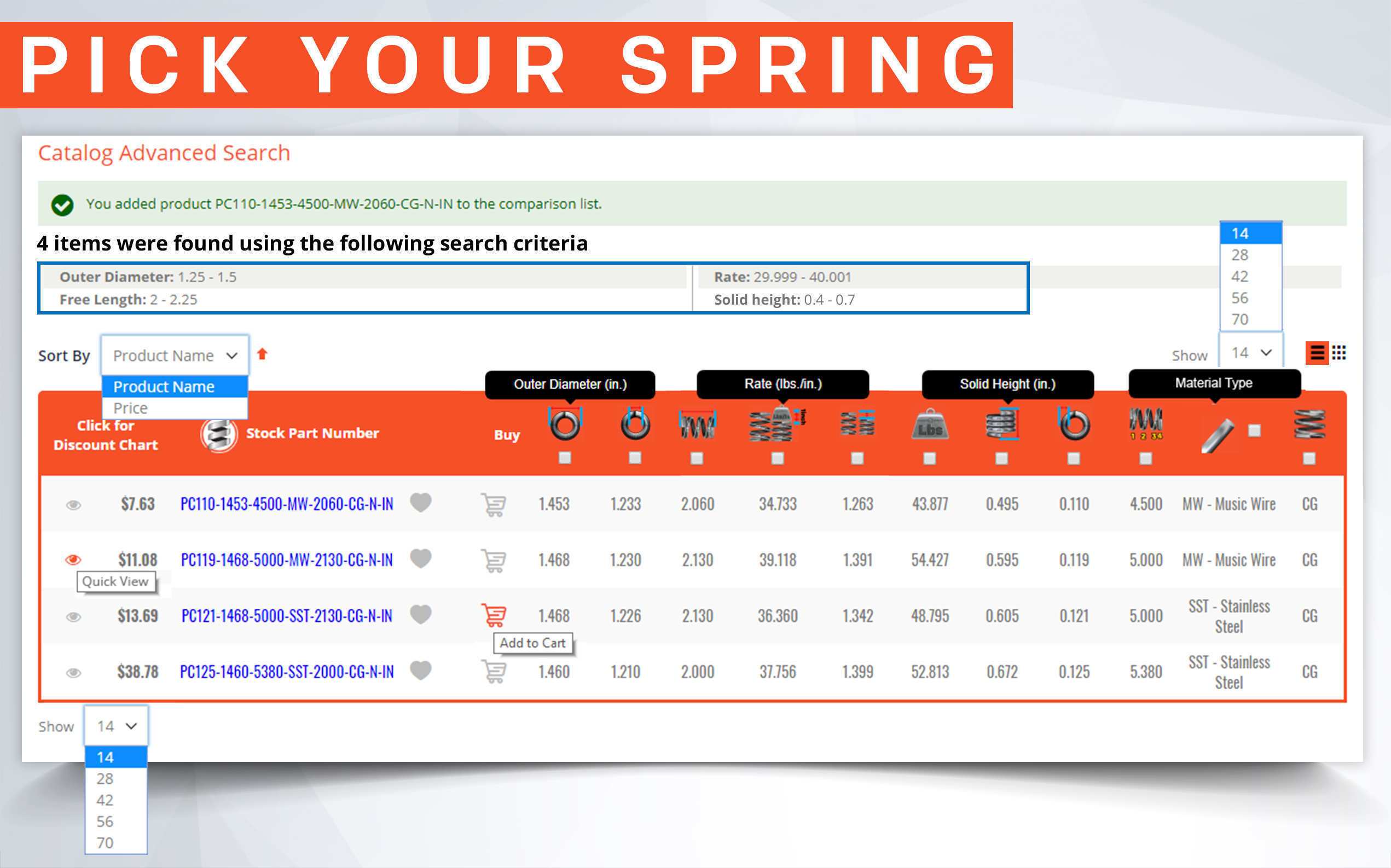

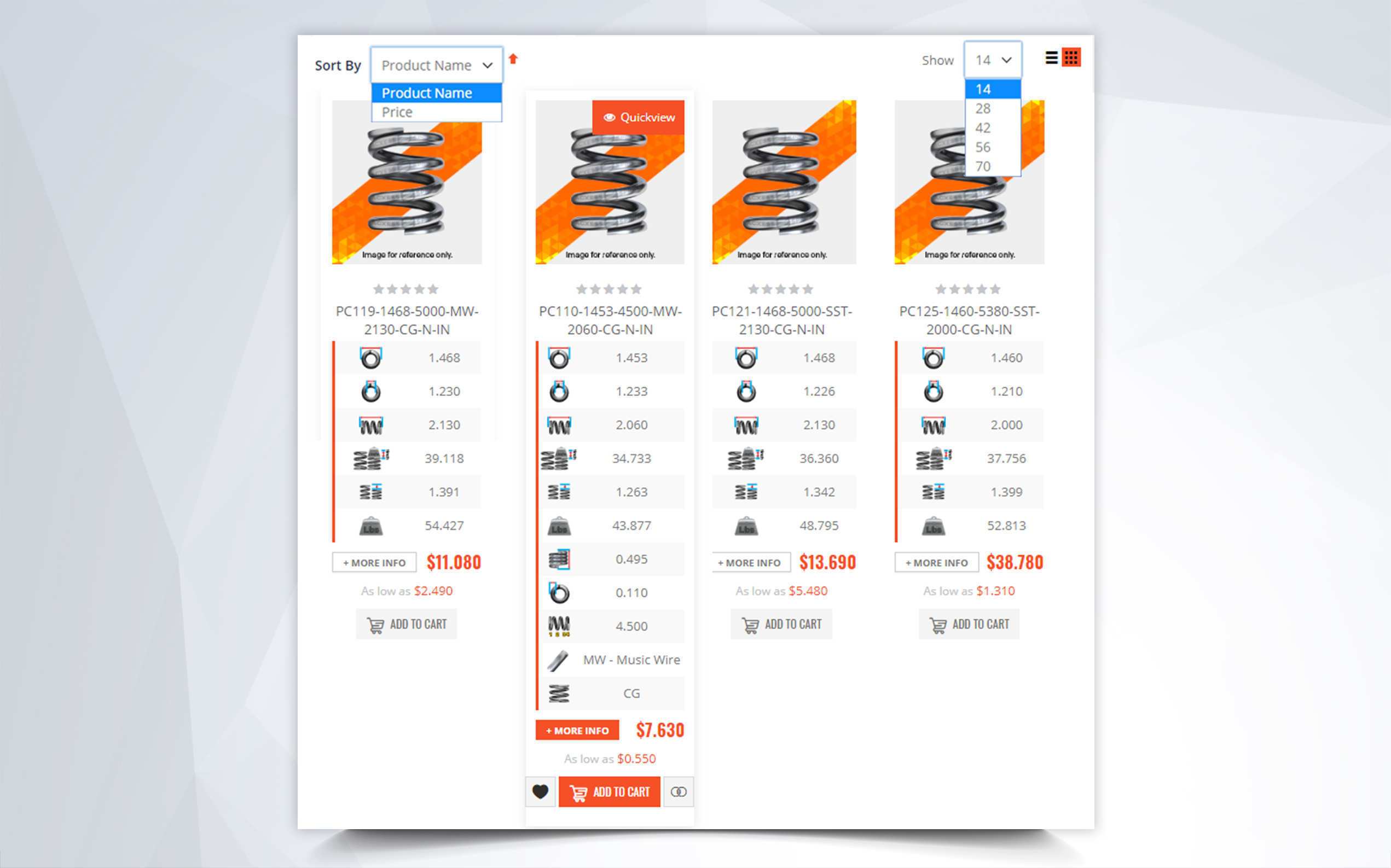

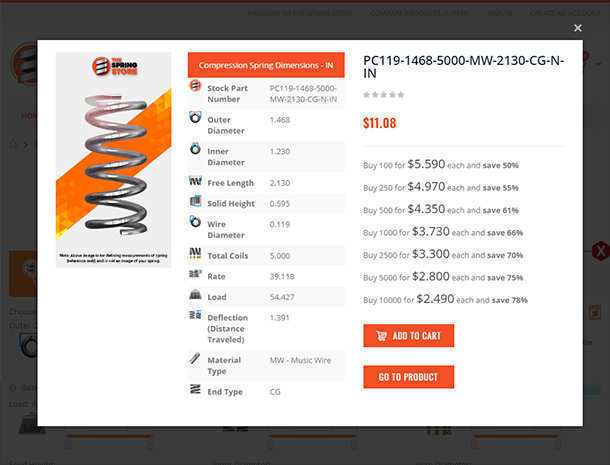

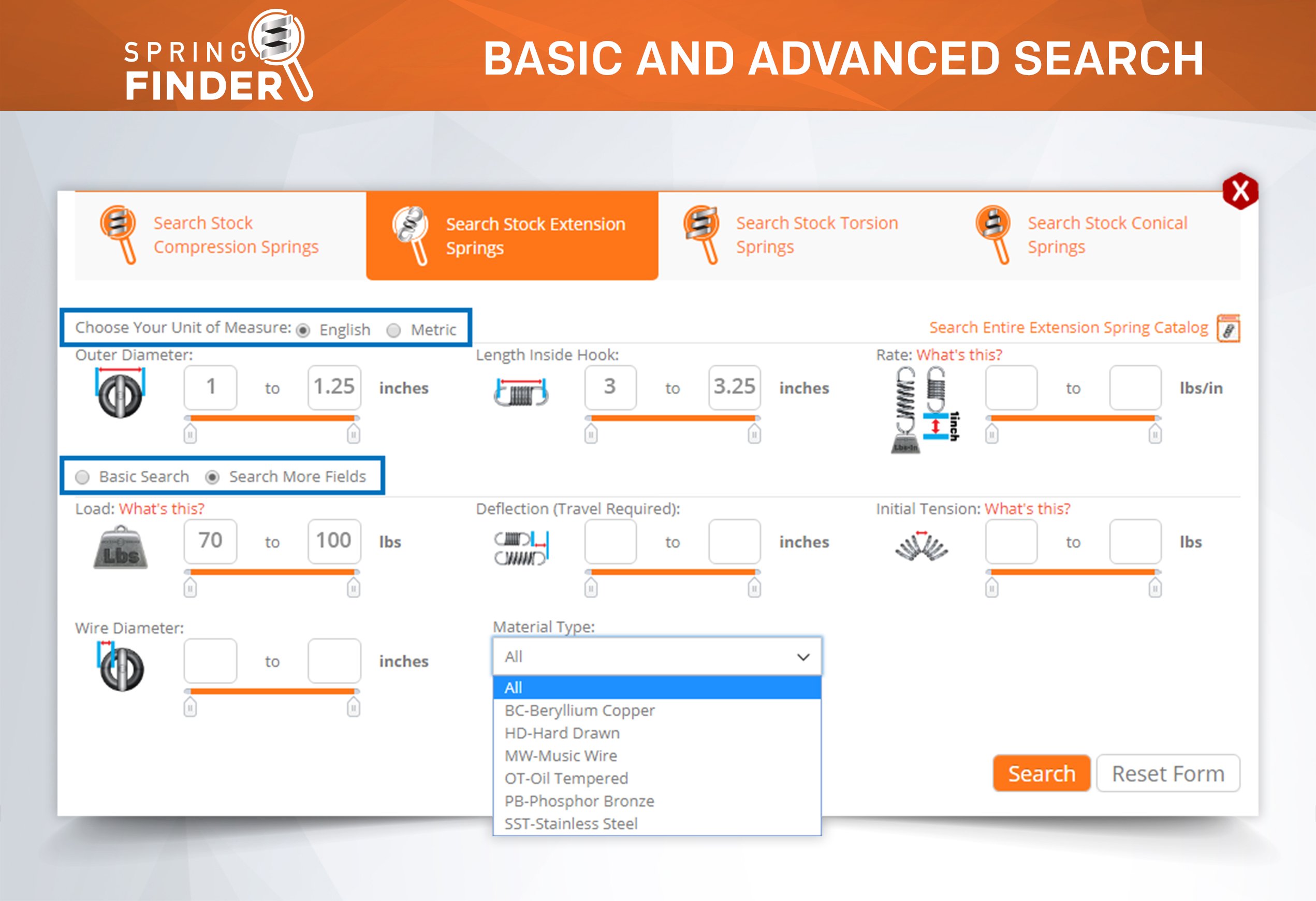

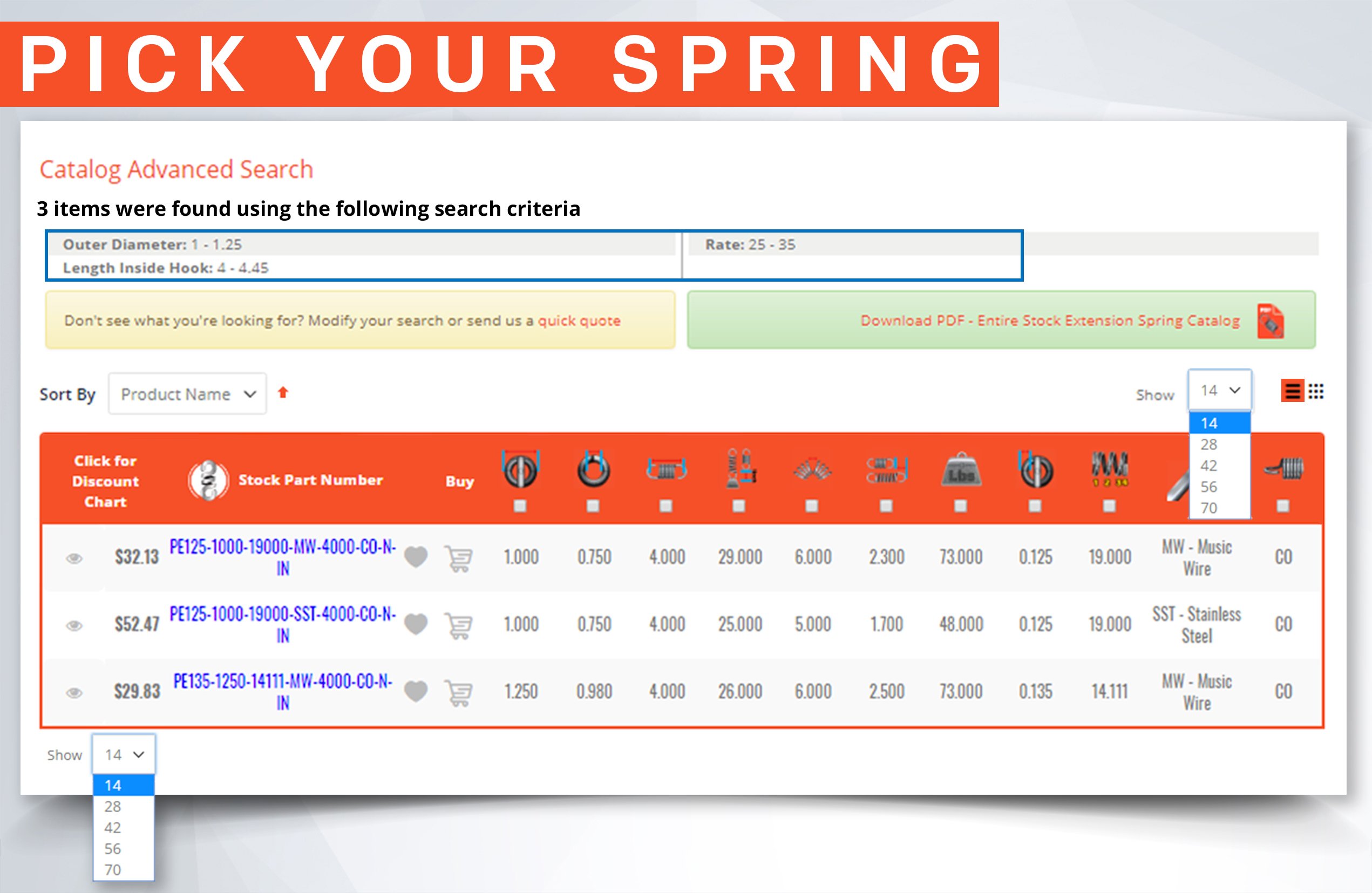

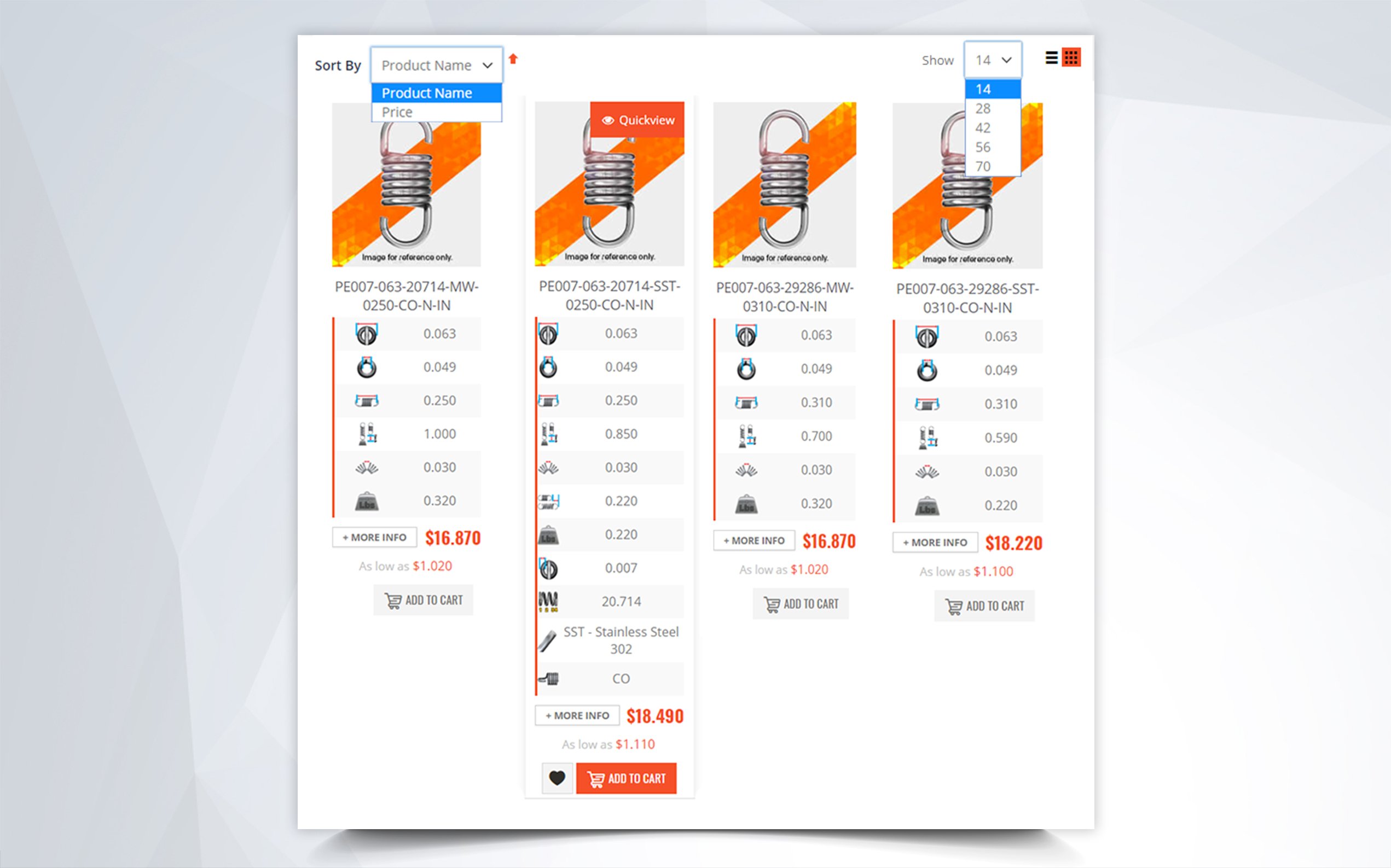

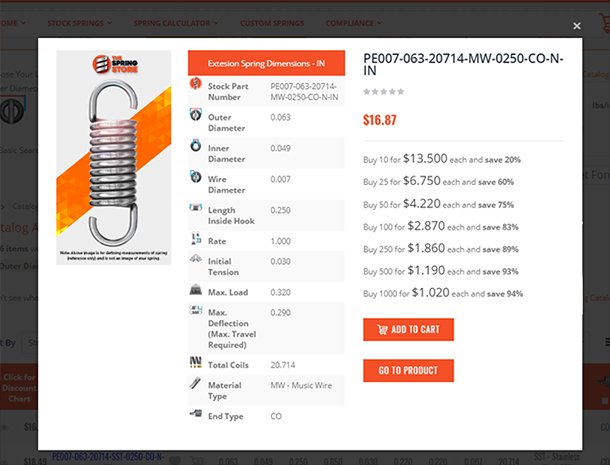

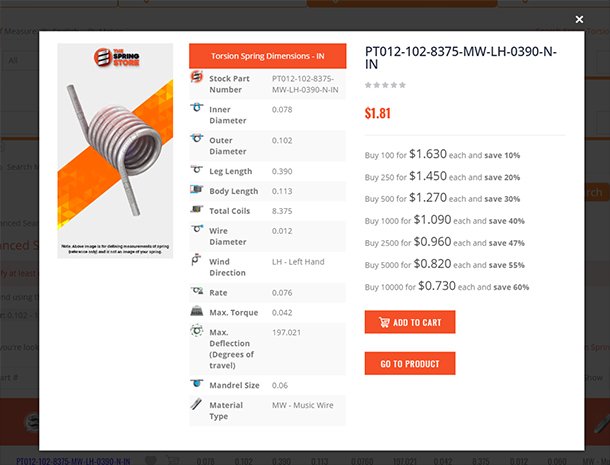

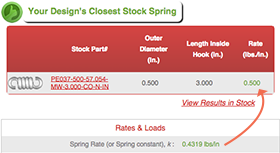

Similar Stock Springs and Closest Stock Spring

As you design your extension spring, Spring Creator will search our extensive tension spring catalogue to determine if your spring is available for immediate purchase. We can also provide you with the closest spring in stock to aid in prototyping stages, saving you time and money.

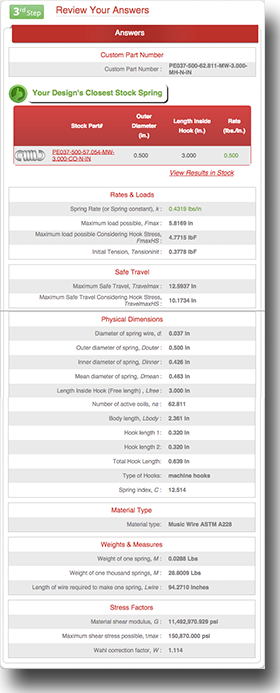

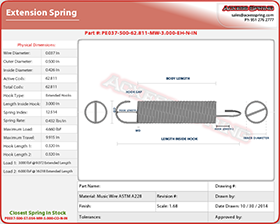

Step 3.) Review Your Answers

Here is where you see all your extension spring design results. From the smallest detail, like inner diameter, to the most important details like spring rate, maximum load considering hook stress, or maximum travel considering hook stress. You will find it all using Spring Creator.

Rates and Loads:

This is where you determine the strength of your spring. The tension spring rate will be highlighted in green since it is the “master” of your spring calculations. Rate determines how much load you will need in order to travel or extend your spring to your desired extended length and vice versa. On the section above Rates and Loads, you will notice that you are provided with your design’s closest spring in stock and the spring rate is also highlighted in green. This is why it is the closest spring in stock, because it is the spring with the most common spring dimensions including spring rate.You will notice that you’re provided with three values,maximum load possible, maximum load possible considering hook stress, and initial tension. The difference between maximum load possible considering hook stress and maximum load possible is that maximum load possible considering hook stress considers your hook’s stress and the material tensile strength to prevent breakage. Maximum load possible, on the other hand, is the load you would be able to reach if your tension spring didn’t have hooks. Initial tension is the force or energy already gathered in your spring’s coils which makes the coils stay “compressed”. Initial tension is released once your spring is extended to a point where you can see light in between the coils.

Safe Travel:

This section provides you with information regarding how much you will be able to extend or deflect your extension spring. You are also provided with two different values here; maximum safe travel and maximum safe travel considering hook stress. Like load, maximum safe travel considering hook stress is the travel you will get out of your current design with hooks while maximum safe travel is the possible amount of travel your spring may achieve if you don’t use hooks.

Physical Dimensions:

You’ve already entered some of your spring’s physical dimensions in step 2 but here you are provided with some more thorough information regarding your spring’s physical dimensions. The dimensions provided are inner diameter, mean diameter, active coils, body length, spring index, hook length 1, hook length 2, type of hooks, and total hook length. Mean diameter is the diameter in between your spring’s inner and outer diameters (from center of wire to center of wire) and it is used along with the wire diameter to calculate spring index. Spring index is the proportional ratio between your spring’s outer diameter and its wire diameter. This helps to determine the manufacturing difficulty of your spring. Active coils are the overall coils of your spring. Active coils is what helps to calculate the body length of your spring which is the length of a coil tension spring without the hooks. Hook lengths 1 and 2 are the individual hook lengths of each hook from the end of the body length to the inside of the end of the hook; these values are added up to provide you with the total hook length.

Material Type:

This section simply provides the material type you chose your spring design to be made of.

Weights and Measures: Here you are provided with the weight of the spring as well as how much wire your spring requires to be made. This section will help in the manufacturing phase of your coil tension spring as well as the shipping phase. You are provided with the weight of one spring, weight of one thousand springs, and length of wire required to make one spring.

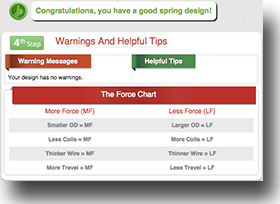

Step 4.) Warnings and Helpful Tips

This section helps to give you specific warnings regarding your spring and tips on how to make adjustments so that you have a reliable spring design. You are also provided with our force chart in case you need your spring to be stronger or weaker. For more force, for example, you would have to make the outer diameter smaller, take some coils out, thicken the wire diameter, or add more travel by increasing the coil spring’s free length. To make your spring weaker, you would have to do the opposite; make the outer diameter larger, add some coils, thin out the wire diameter, or make less travel for your load by making the free length shorter. The warnings and tips/solutions you might get are the following:

Warning: Your index is too small (below 4) which makes it difficult to manufacture.

Tip: In order to increase your index you will need to increase your outer diameter or decrease your wire diameter.

Warning: Your index is too large (above 15).

Tip: In order to decrease your index you will need to decrease your outer diameter or increase your wire diameter.

Warning: Your inputs have generated invalid or negative answers

Tip: Please adjust your inputs accordingly.

Warning: Hook length 1 + Hook length 2 is greater than or equal to your length inside hooks.

Tip: Your combined hook length cannot exceed your length inside hooks. To fix this problem please increase the length inside hooks, decrease your wire diameter, decrease your outer diameter, or if you are using extended hooks please decrease your hook length(s).

Warning: Hooks are high stressed.

Tip: The stress that is being put on the hooks of this spring exceeds the maximum psi limits of the wire. The hooks may break and fatigue due to stretching the spring past the maximum safe travel considering hooks stress value. To fix this problem, here are some options: change the wire type to a stronger material, increase the wire diameter, or increase the outer diameter of the spring.

Warning: The force in L2 is less than the force in L1.

Tip: Your L2 must be greater than your L1. The formula for load is: rate * distance traveled = load. Thus if your distance for L2 is greater than L1, your load at L2 must be greater.

Warning: Your load exceeds the max safe load.

Tip: If you need to reach a load that takes you beyond the max load, you ned to change your input values. Here are some options: increase the number of coils, increase outer diameter, or decrease wire diameter.

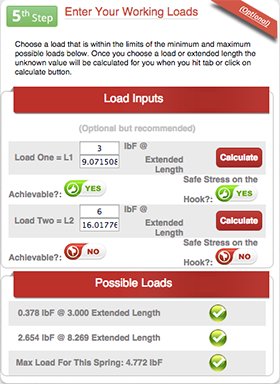

Step 5.) Enter Your Working Loads

Choose a load that is within the limits of the minimum and maximum possible loads below. Once you choose a load or extended length, the unknown value will be calculated automatically when you hit the tab key or click on calculate.

Note on Load inputs: You must enter a load value that is within the “Possible Loads” list that is below the load inputs. If you enter a load value that’s NOT possible ( or beyond the Maximum

Load Possible Considering Hook Stress) the calculator will display a “Red Thumbs Down” icon telling you that you’ve gone further then the “Maximum Load Possible Considering Hook Stress” listed on step 3. If you enter a possible load, the calculator will display a “Green Thumbs Up” Icon telling you the load value is possible. Also, if you enter an extended length (travel) within the “Maximum Safe Travel Considering Hook Stress” listed on step 3 and hit tab or calculate the calculator will display either a “Green Thumbs Up” if the extended length (travel) is possible or a “Red Thumbs Down” if the extended length (travel) is NOT possible. Please refer to your “Maximum Load Possible Considering Hooks Stress” and “Maximum Safe Travel Considering Hook Stress” listed on step 3 for these values represent what your spring can achieve in load and travel. Going beyond these values is not recommended because your tension spring will take a SET an NOT return to it’s original length inside hooks. Also, you will lose load on your spring or worse, you will cause breakage. If you need more travel add more coils, or make your outer diameter larger and increase your wire diameter.

Step 6.)

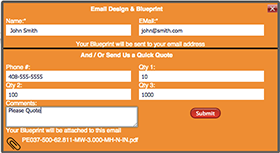

Generate Blueprint:

Click this and you will get a real time blueprint of your exact spring design which is editable. You will have a complete spring blueprint ready for manufacture. The editable fields you can add to this blueprint are: Part Name, Part Number, Drawing #, Drawn By, Revision#, Tolerances, Approved By, Finish (plating) and Manufacturing Notes. Once you’ve edited your blueprint click “Update Blueprint” and all the fields that you edited will be updated and reflected on your blueprint.

Get a Instant Spring Quote of Your Spring Design:

This feature lets you quickly send us a quotation. The spring blueprint will automatically be attached to the quote.

Email Design & Blueprints:

Once your comfortable with your blueprint click on the “Email Design & Blueprints” and email the PDF blueprint directly to yourself, colleagues, and potential clients without leaving the Spring Creator App, increasing productivity and efficiency.

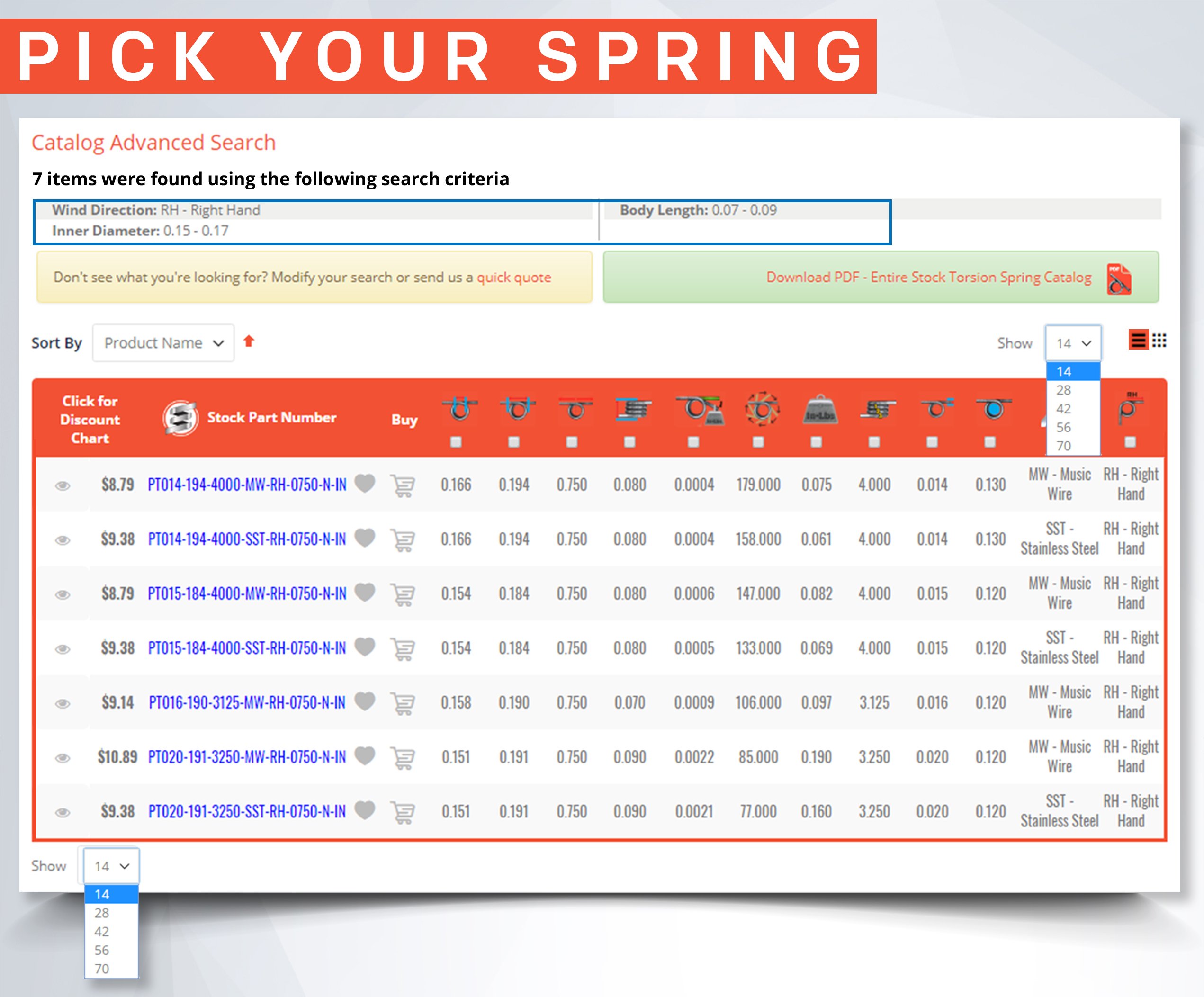

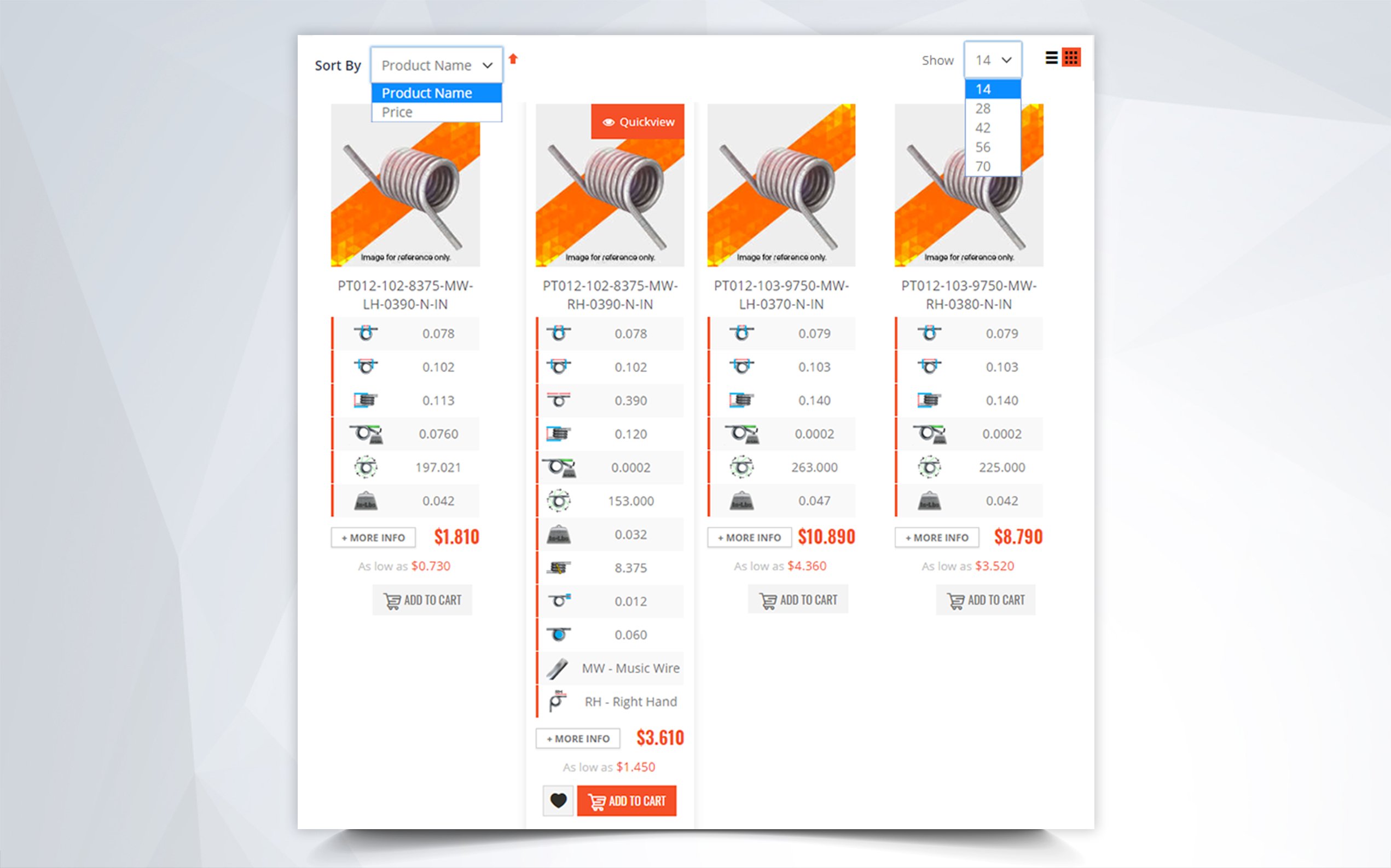

Similar Springs In Stock:

This link shows you similar springs and the closest spring in stock to your design that is ready for purchase. As you design your spring, Spring Creator will search our extensive spring catalogue to determine if your spring is available for immediate purchase. This will aid you in the prototyping and testing stages, saving you time and money.

We really appreciate you using “Spring Creator” we work to meet your spring design needs and to supply you with a complete and comprehensive spring calculator. If you need further assistance on designing your spring please give us a call @ 951-276-2777 we are here to help!

We welcome your comments or suggestions to make “Spring Creator” even better. Please email us at: support@thespringstore.com