The Three Main Types of Metal Coil Springs

There are three main types of springs. Compression, Extension, and Torsion. These three types of springs each perform different functions. It is important to know the different actions that each spring carries out in order to define what type of metal spring you need. In this article, we will break down the basic information you need to know about each type of coil spring.

Three Types of Springs

Compression Springs

Compression springs are the most common type of springs in the industry. These mechanical devices in the shape of a helix made from spring wire are used to store or release energy. Compression springs can be used to absorb shock or maintain a force between two surfaces.

Compression springs are named that way because the name defines the action the spring carries out when a load or force is placed on it, it compresses.

Compression springs have pitch in between the coils in order to store energy when a load or force is placed on it. Once the load or force is removed it then releases such energy and returns to its original form. In other words, it ¨springs back.¨

Compression springs usually range in wire sizes from 0.006 inches to 1.250 inches. More standard stock spring sizes are around 0.06-0.6

Compression Spring Applications

Some applications for compression springs include springs in pens, pogo sticks, and all kinds of buttons on machines that require a bounce back motion.

Extension Springs

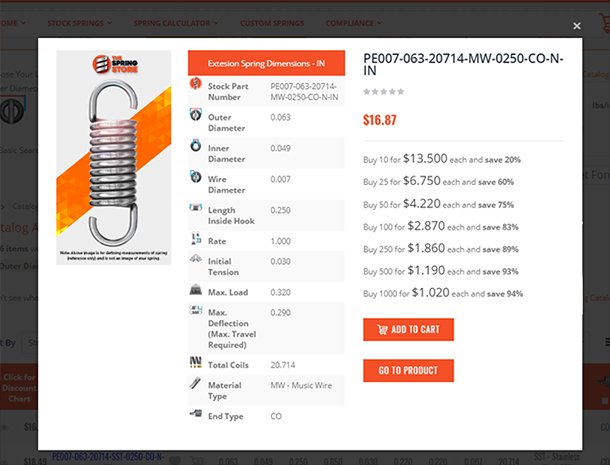

Extension springs, also known as a tension spring, are helical wound coils, wrapped tightly together to create tension. As their name states, the action that it carries out when a load or force is placed on the ends is to extend or expand. That is why they can also be called expansion springs sometimes.

Extension springs usually have hooks, loops, or end coils that are pulled out and formed from each end of the body. The function of an extension spring is to provide extended force when the spring is pulled apart from its original length.

The hooks tend to be the weakest point of the extension spring. If there is a risk of the hook breaking or bending due to the level of force it needs to withstand, then it is recommended that t instead of hooks, bolts be placed on the ends to attach it to the necessary place.

Extension Spring Applications

Helical extension springs are used in devices where a piece is mobilized by a force and needs to return to its original position when the force is taken off. Its hooks allow for it to grab on to your device’s pieces and be pulled/extended.

Extension springs are used in trampolines, push and pull levers, rocking horses, screen doors, and anywhere else extended force is necessary.

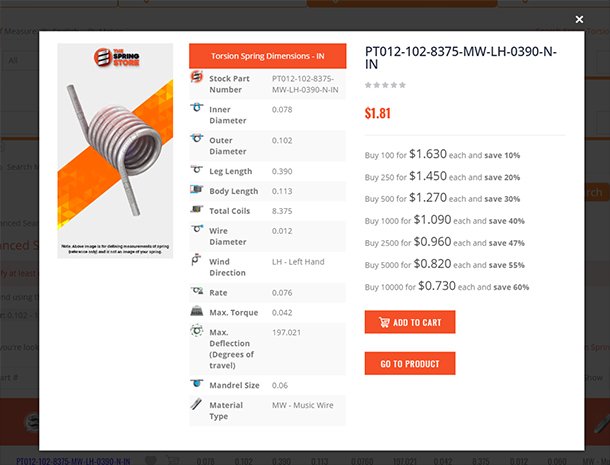

Rotational Springs

Torsion springs are the least common of the three main types of springs. They can also be called torque springs, torsional springs, or rotational springs. All of these names describe the action or motion that the spring carries out when a load or force is placed upon it.

Torsion springs are wire springs whose coils twist to perform a rotational motion when torqued. They then release this stored energy and eject it when the force or load is removed.

What makes torque springs special is that their shape and function as a close wound coil spring is to eject a radial force thus producing torque instead of a linear load.

Torsion Spring Applications

Some examples of items that use torsion springs to function are: clocks and watches, clips, and trailer ramps.

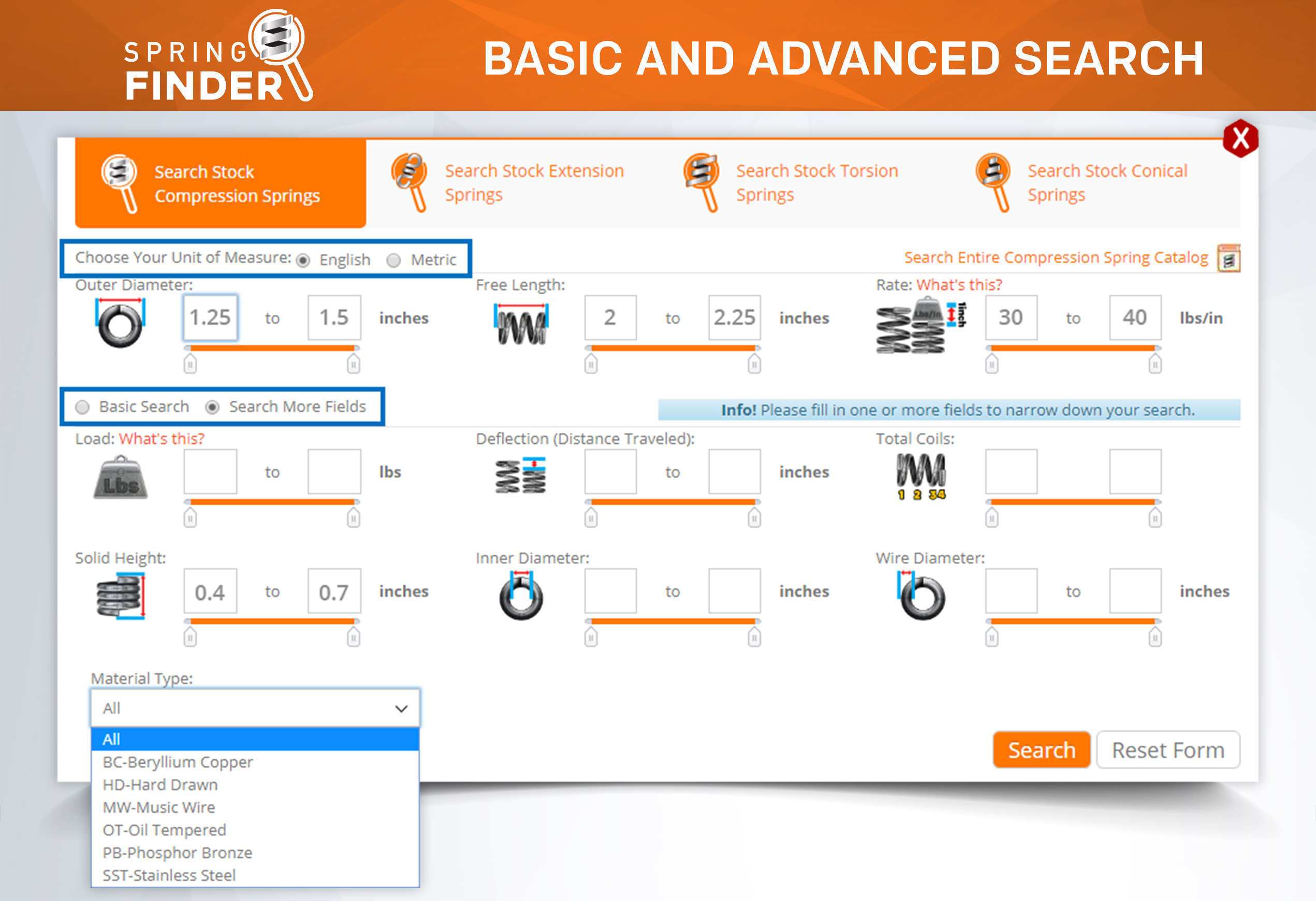

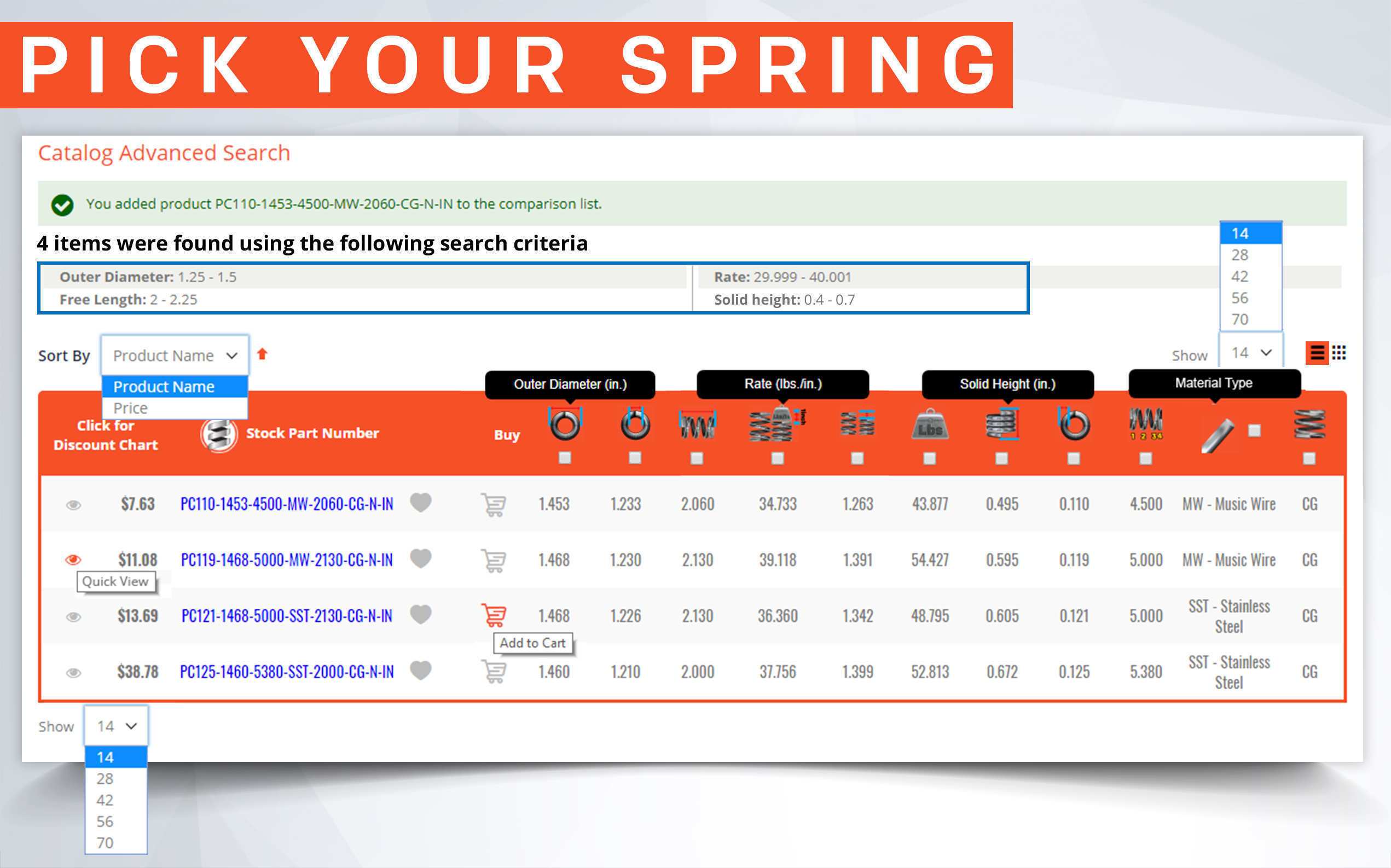

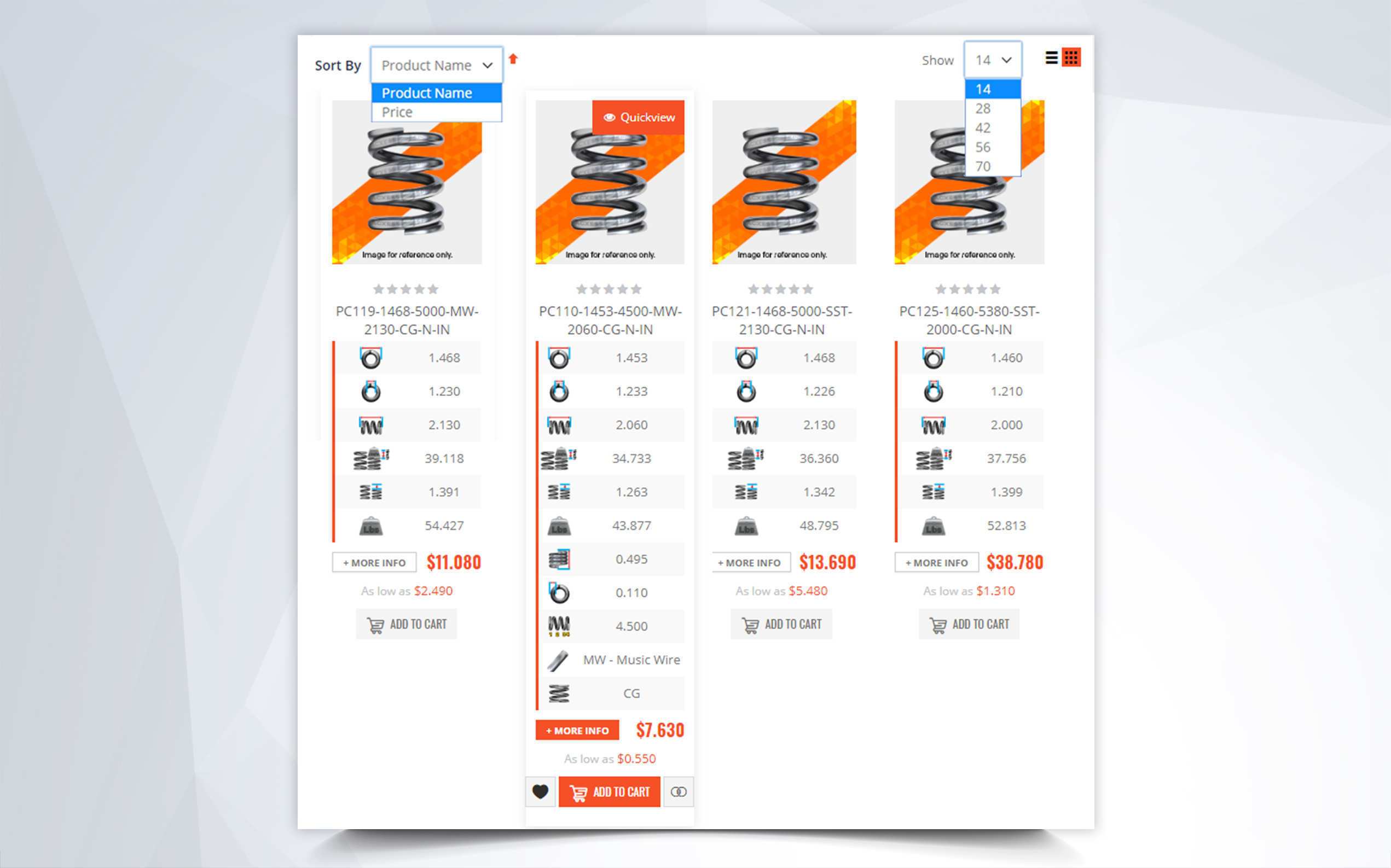

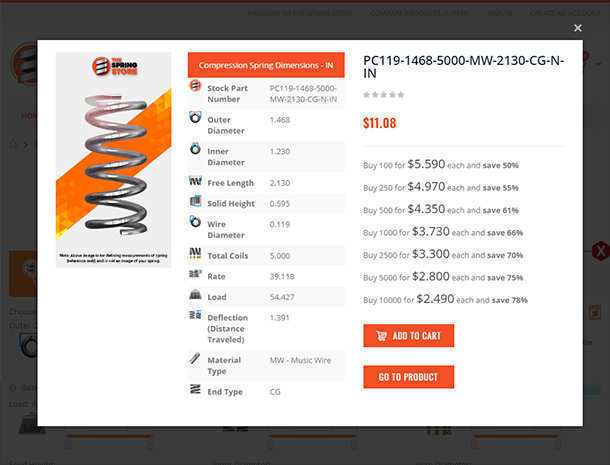

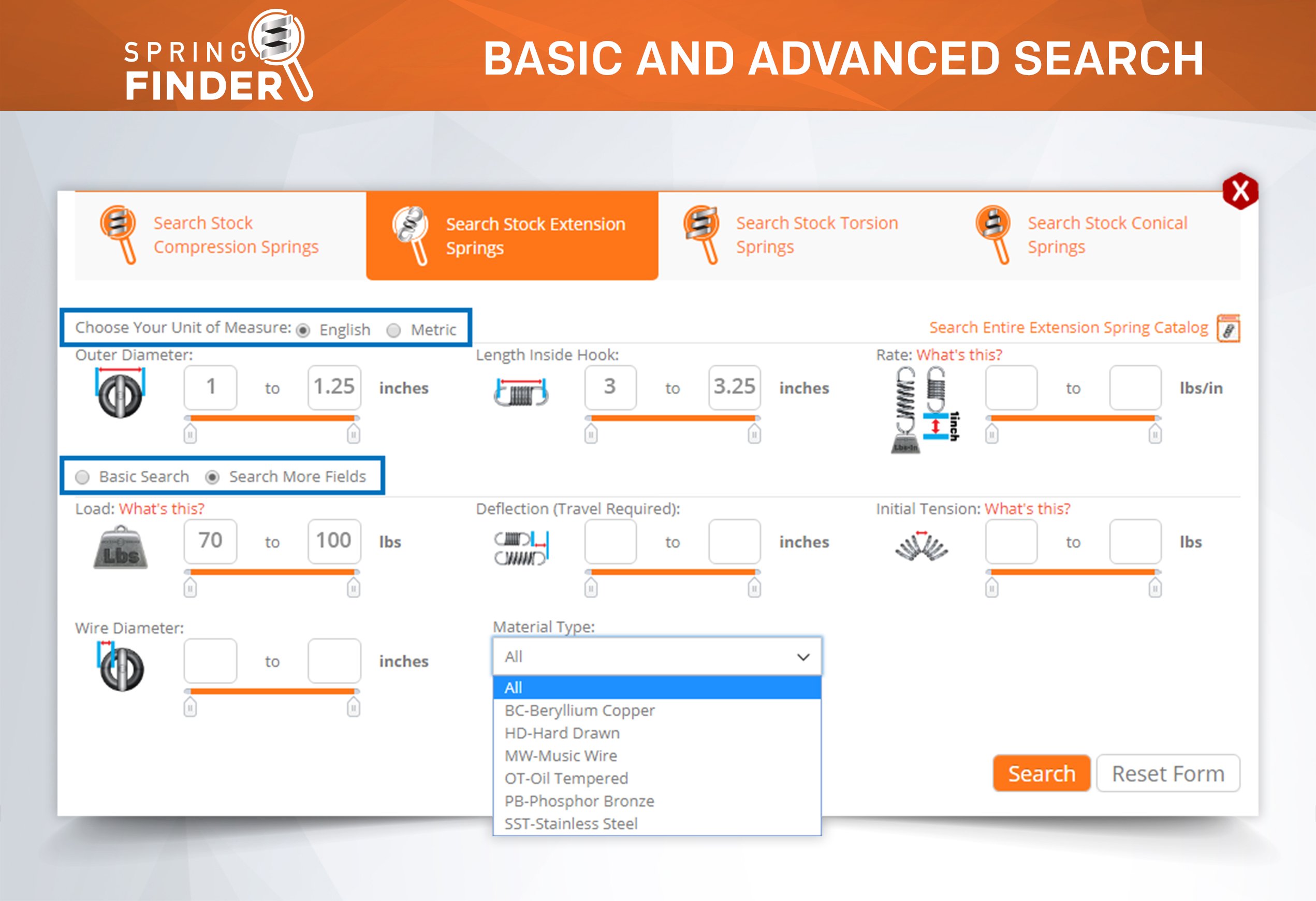

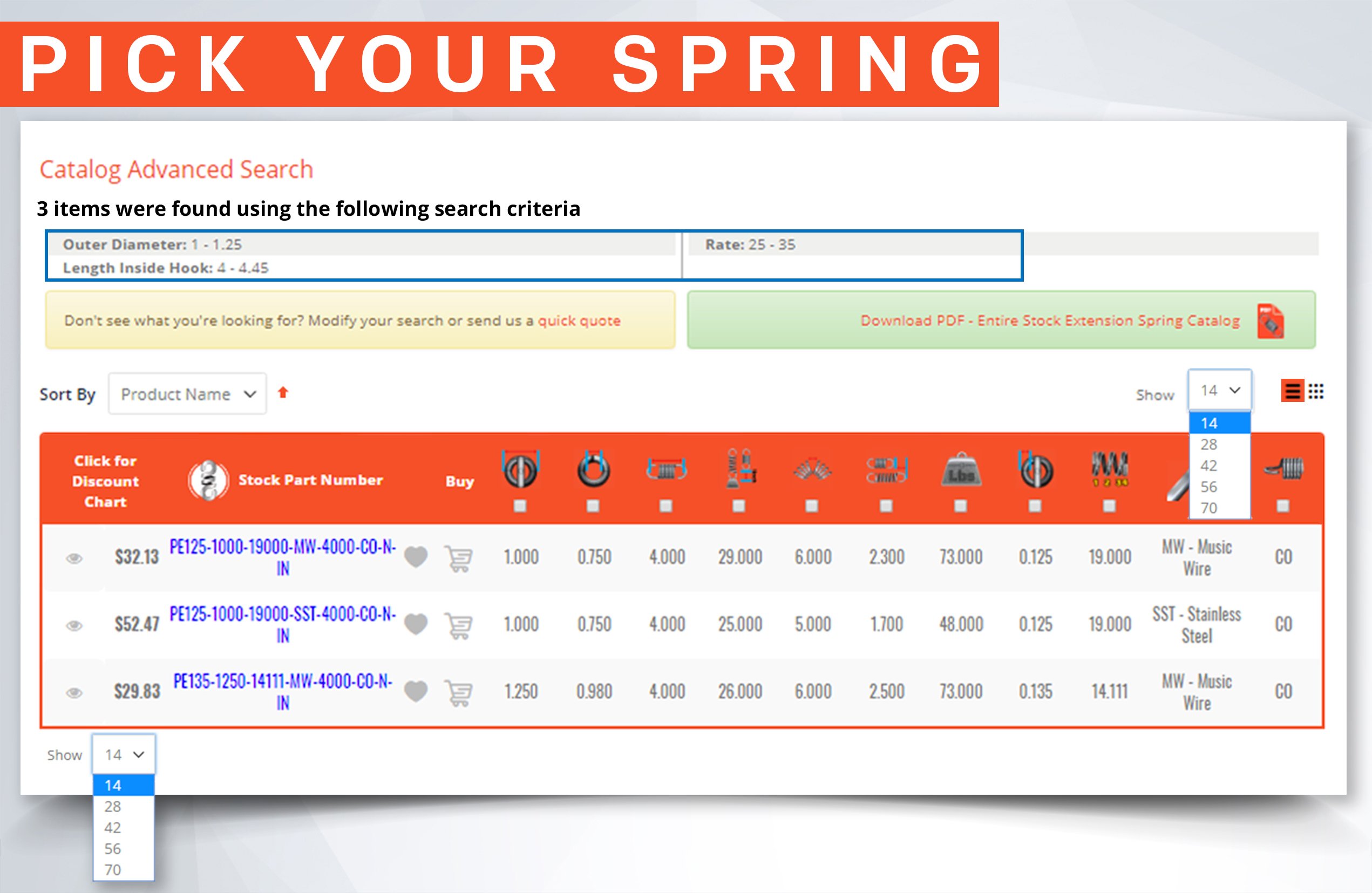

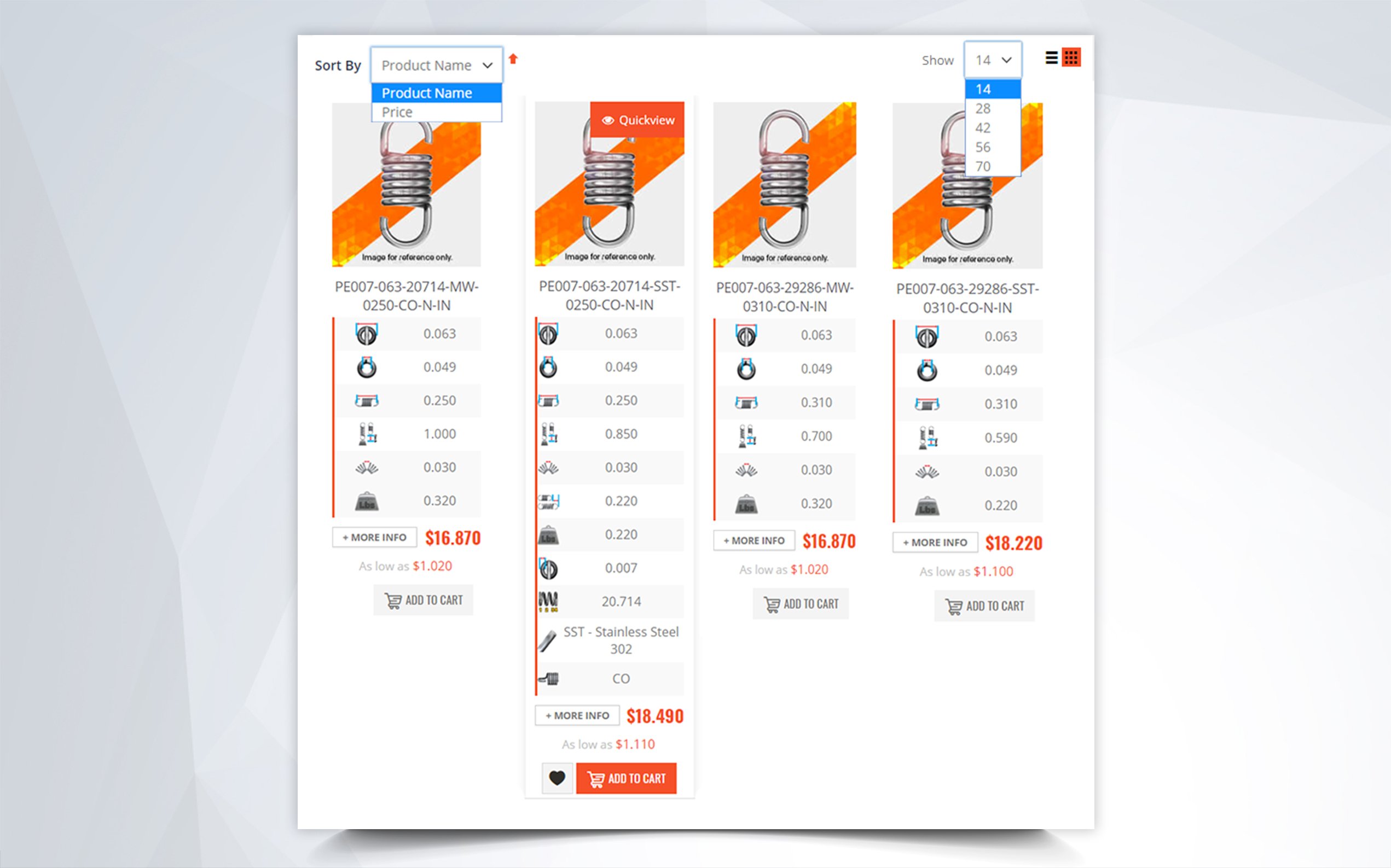

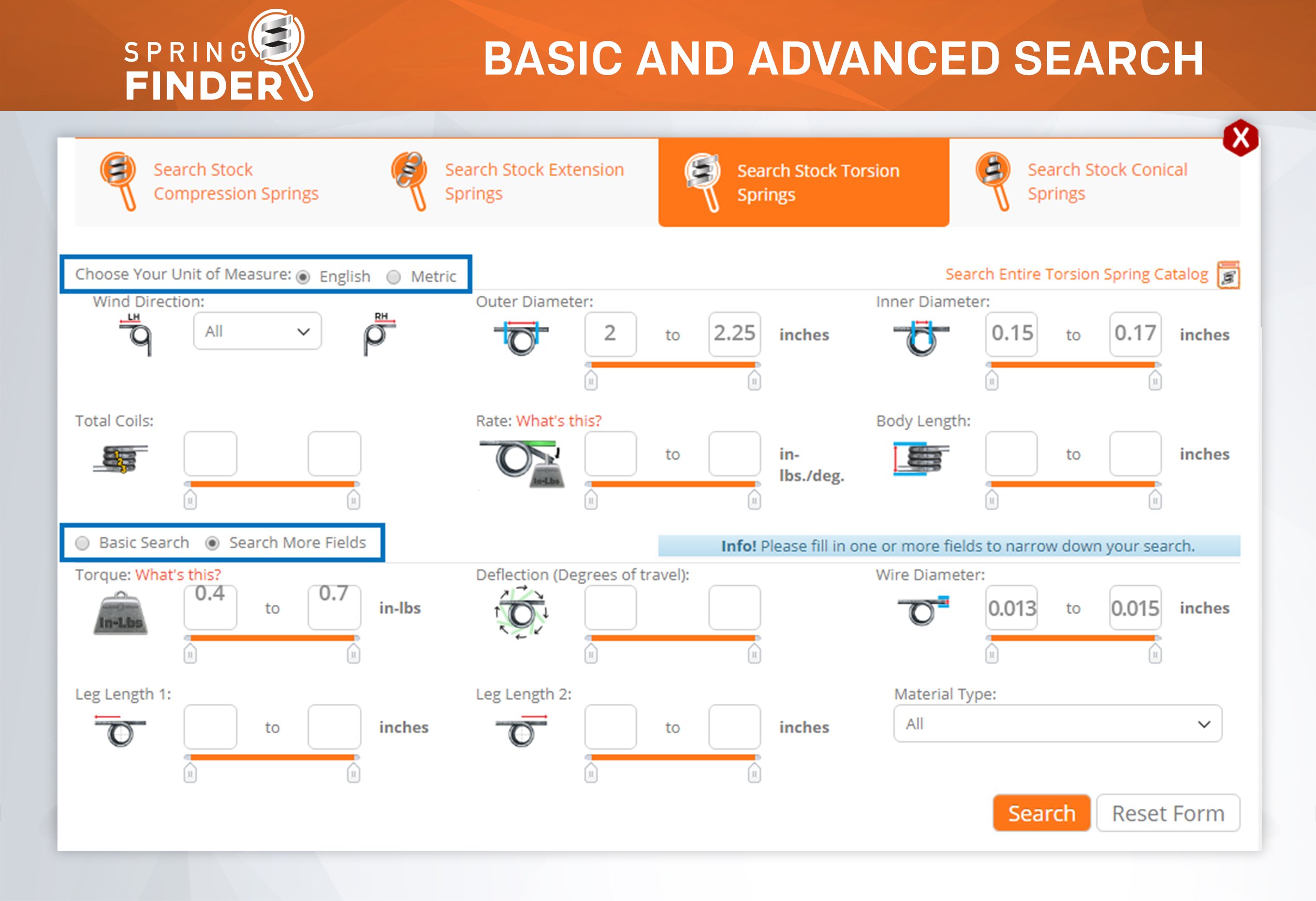

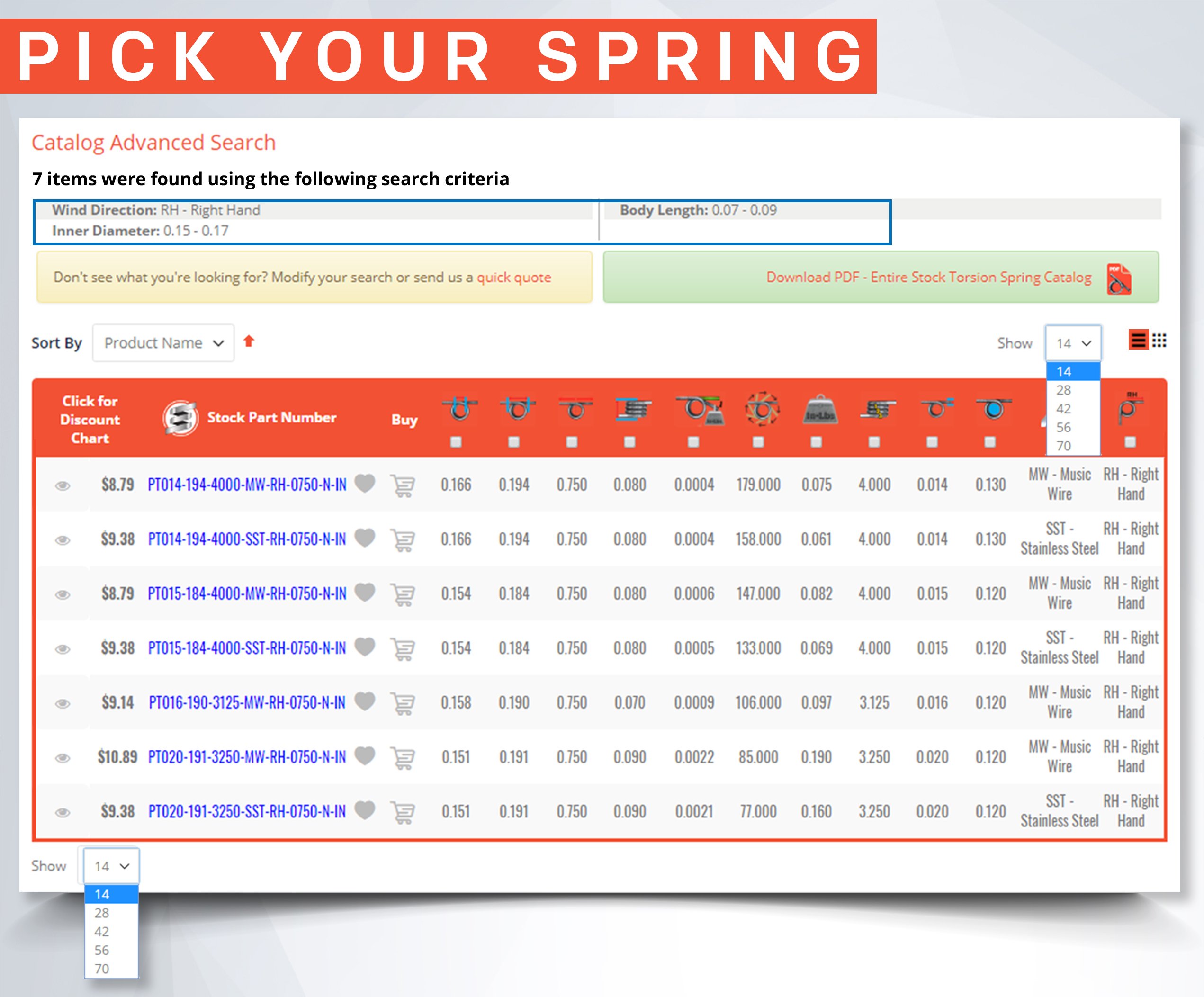

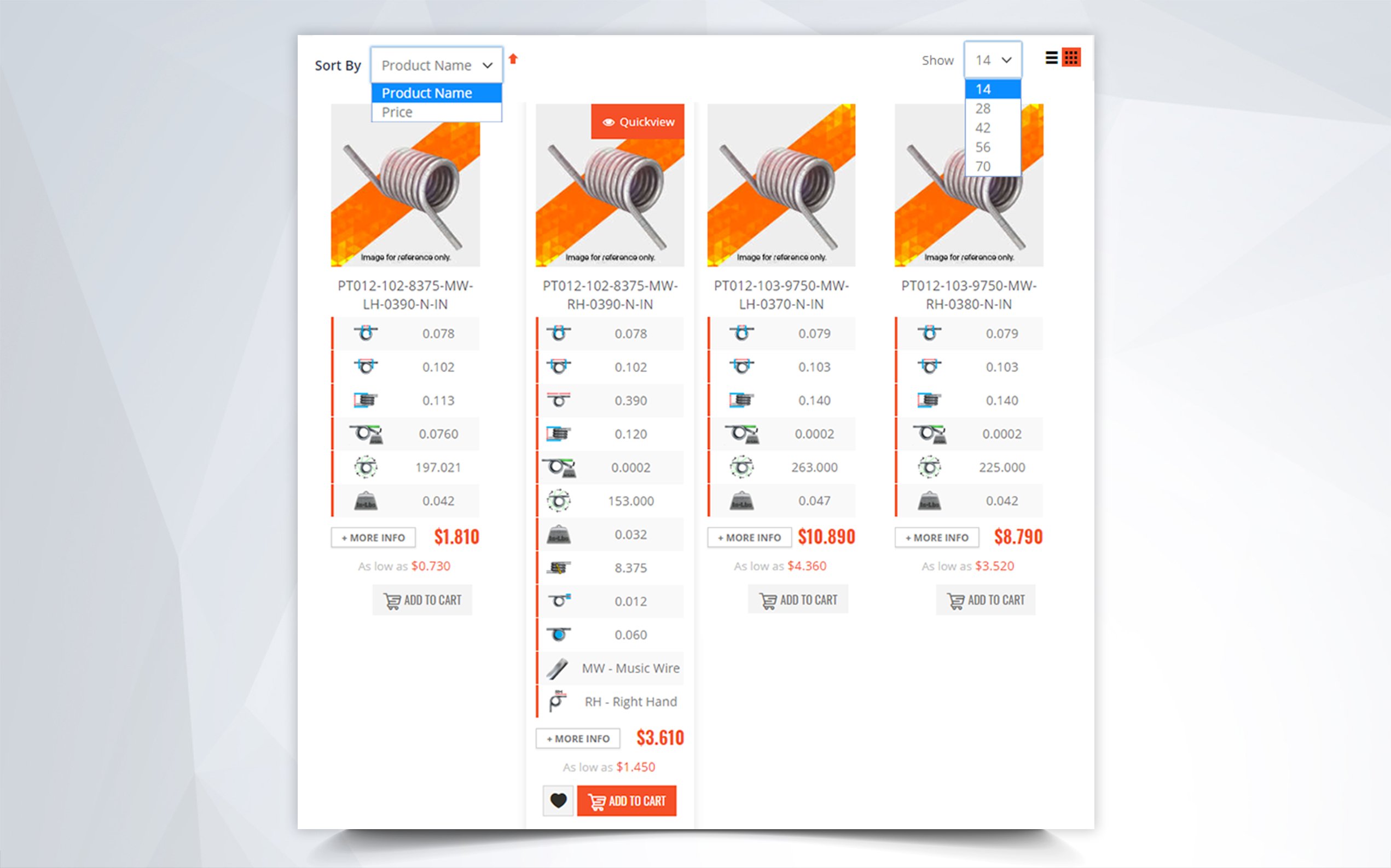

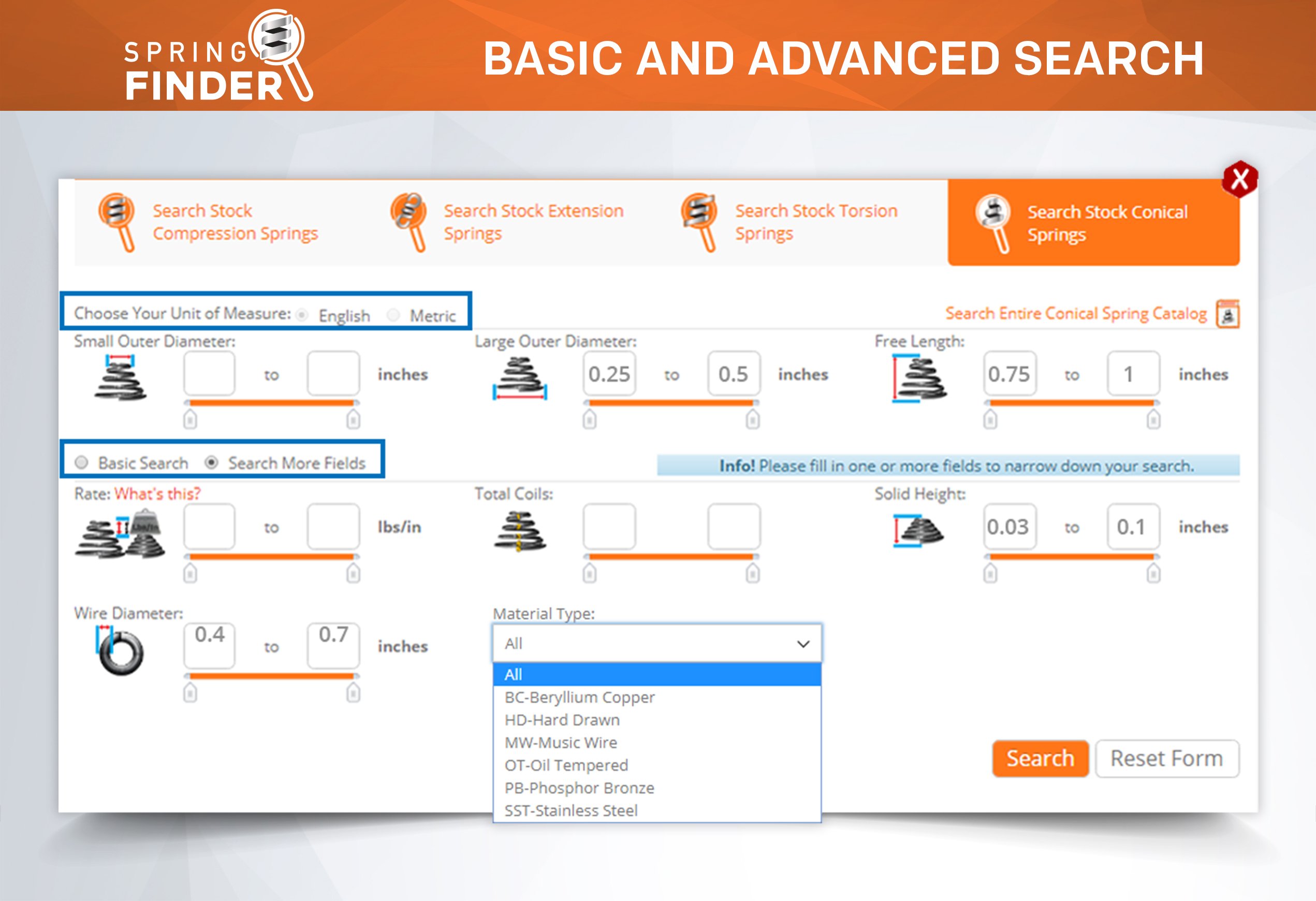

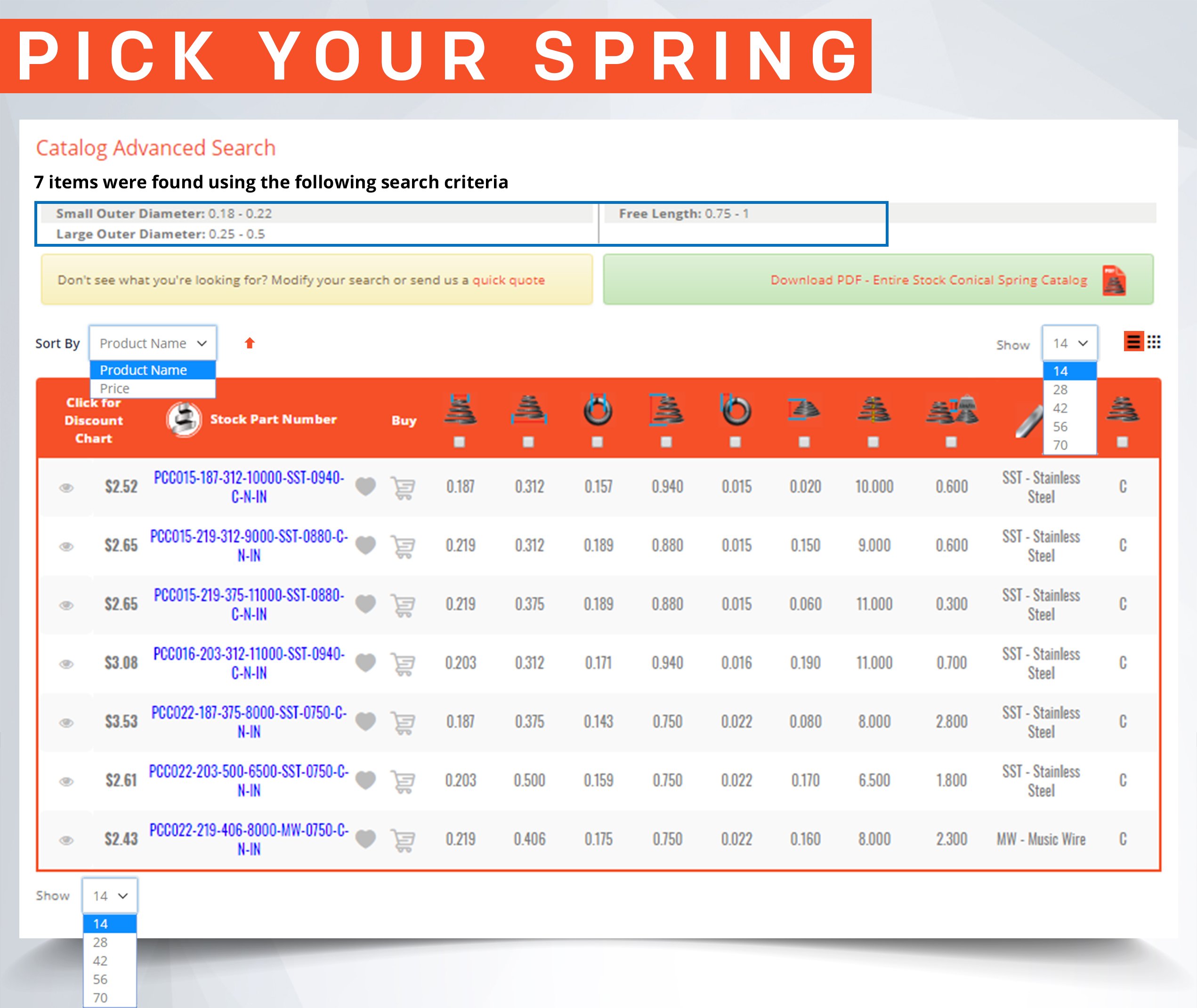

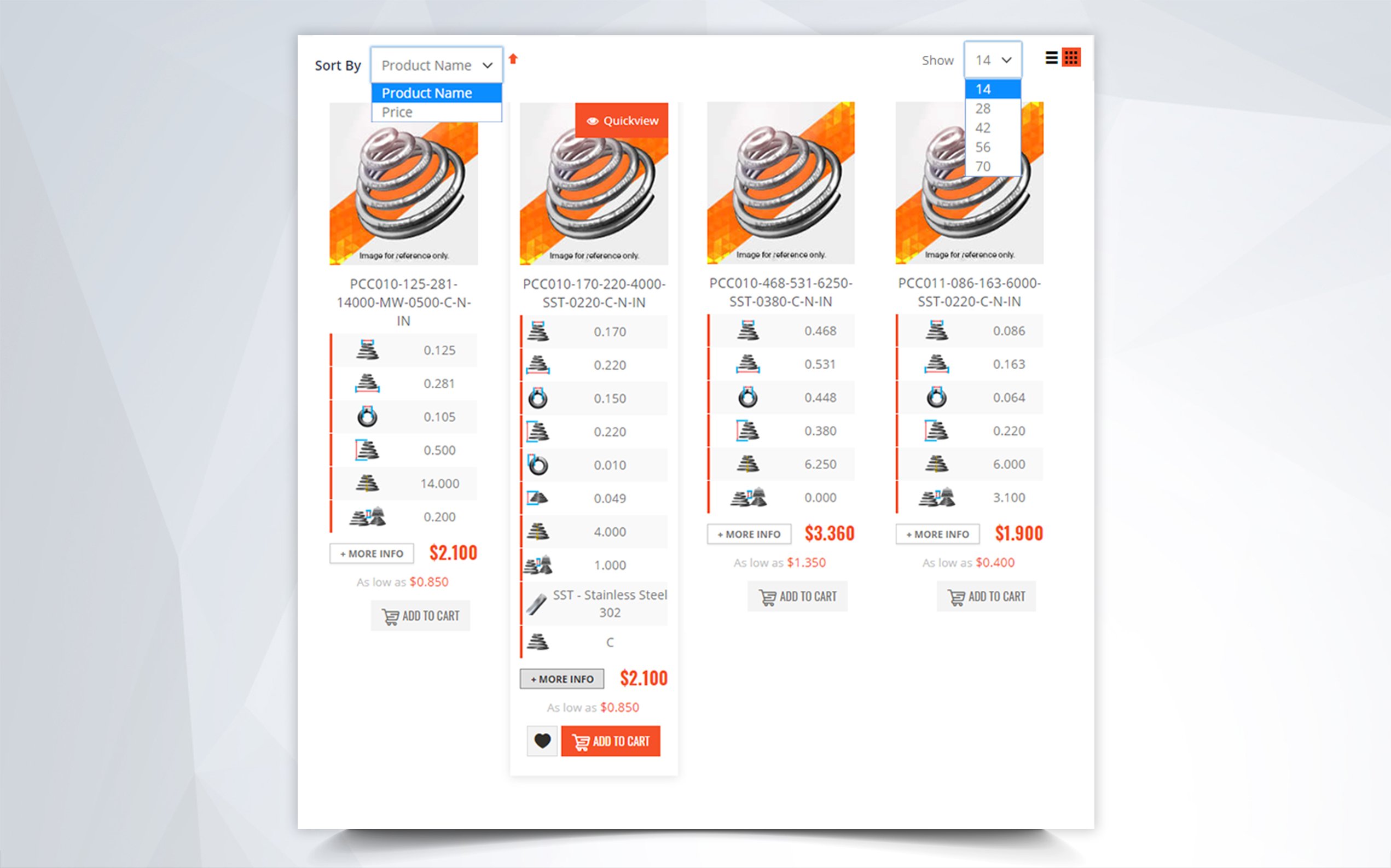

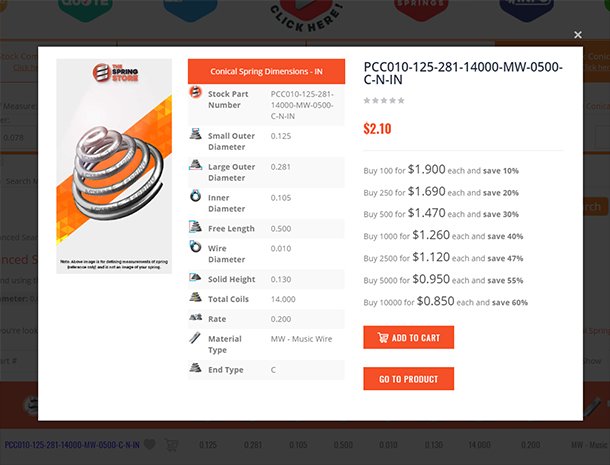

Any of these spring types can be purchased as a stock spring or designed and bought as a custom item so it can match highly specialized needs. Whether you need a compression, extension, or torsion spring, you can find it here, at StockSpringsCatalog.com. We carry tens of thousands of compression spring designs in stock, as well as a large variety in tension and torsion springs. Start looking for the perfect spring in one of our spring finder tools here: Stock Compression Springs.