Understanding Closed and Open Coil Helical Springs

Open coil helical springs have pitch between the coils while closed coil helical springs have no pitch. There is quite a variety of different terms used for this type of springs, so we will address just a few. Our goal today is to help you understand more about each of their differences and functionality.

Open coil springs are named this way because of the open space that is left between is coil as it is manufactured and wound. That open space between each coil is named ¨pitch.¨

Open coil springs have space between each coil in order to compress and store energy and then release this as the spring returns to its original position when such force is removed.

Open Coil Helical Springs AKA Open Wound Springs

It is common to think that open coil springs are only compression springs. However, there are several types of open wound springs. Open coil springs can also be referred to as ¨open wound springs.¨

Although the most common type of open wound or open coil springs is compression springs there are also some types of torsion springs that require a torque and compression motion to be performed and therefore can be manufactured with a pitch between the coils.

Closed Coil Springs AKA Close Wound Springs

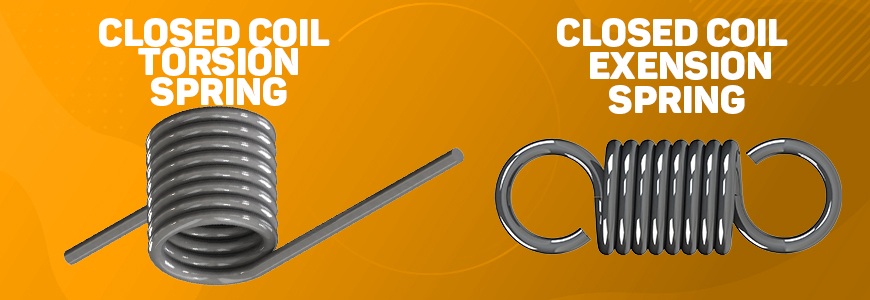

Closed coil springs, on the other hand, are named this way due to the lack of space between the coils. These types of springs are manufactured by eliminating the pitch between the coils and therefore all the coils are close together.

Closed coil springs are manufactured by tightly coiling each helix one after the other and they perform a different functional motion than open coil springs. While open coil springs compress as they compact and eliminate the space between coils, closed coil springs tend to extend or expand creating space between the coils when force is applied to the ends. However, this is not always the case.

Although tension or extension springs are the most common type of closed coil springs they are not the only. Most torsion springs are also closed coil although these perform a torquing motion instead of an expanding movement. When a torsion spring withstands a force it will tend to torque or rotate and the closed coils might compact even closer together that is why it can be both open or closed wound.

We hope this information makes it simple to understand that thee commonly used term of closed or open coils or closed or open wound springs refer to the same thing: the way the coils are positioned in the spring. If you need further clarification you can read here:

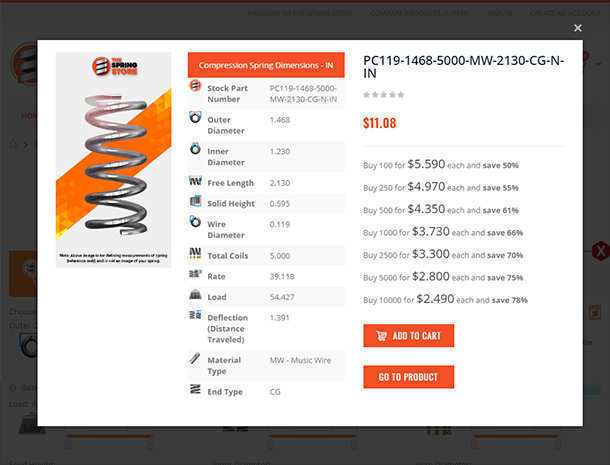

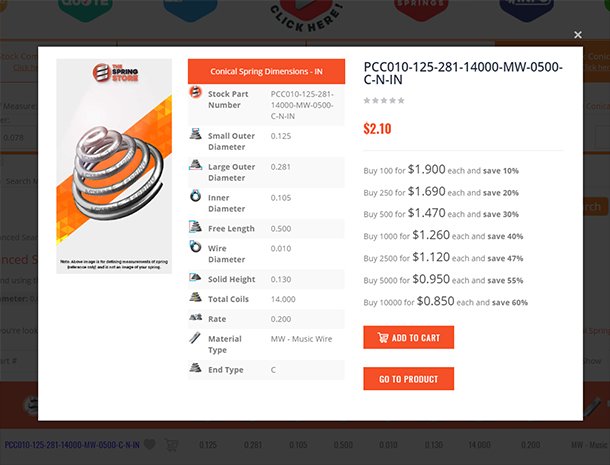

Buy Closed Coil or Open Coil Helical Springs At The Best Price

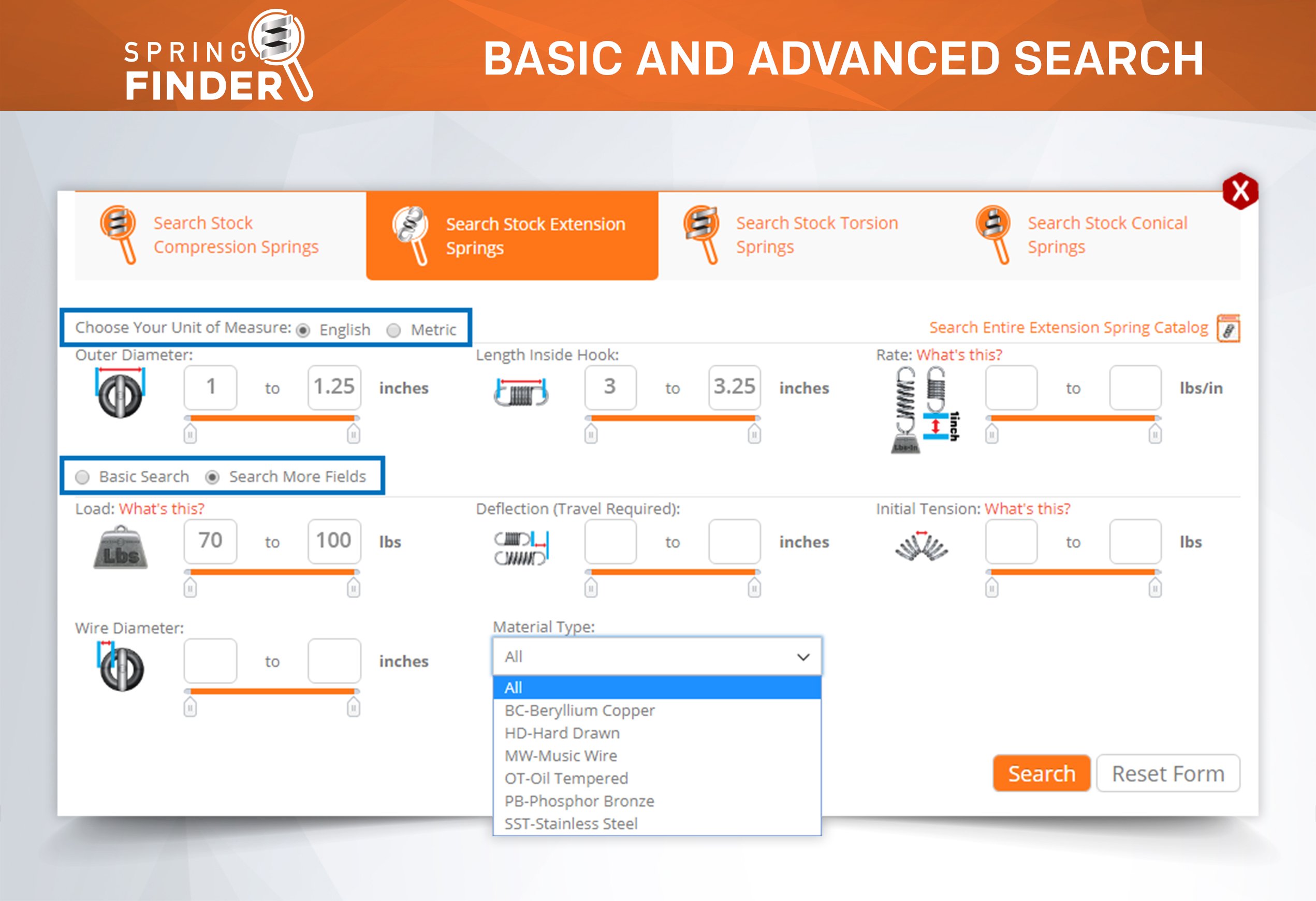

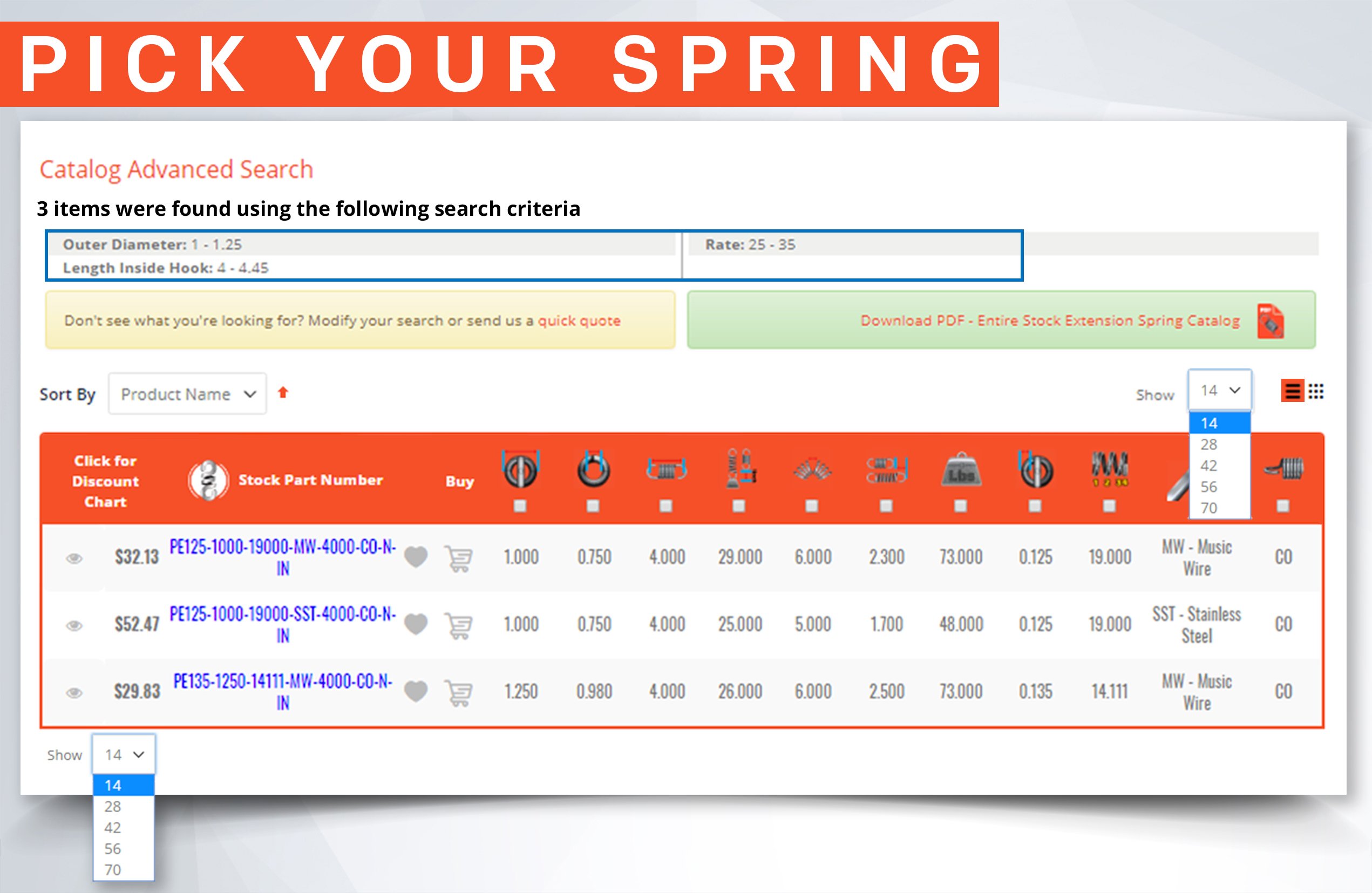

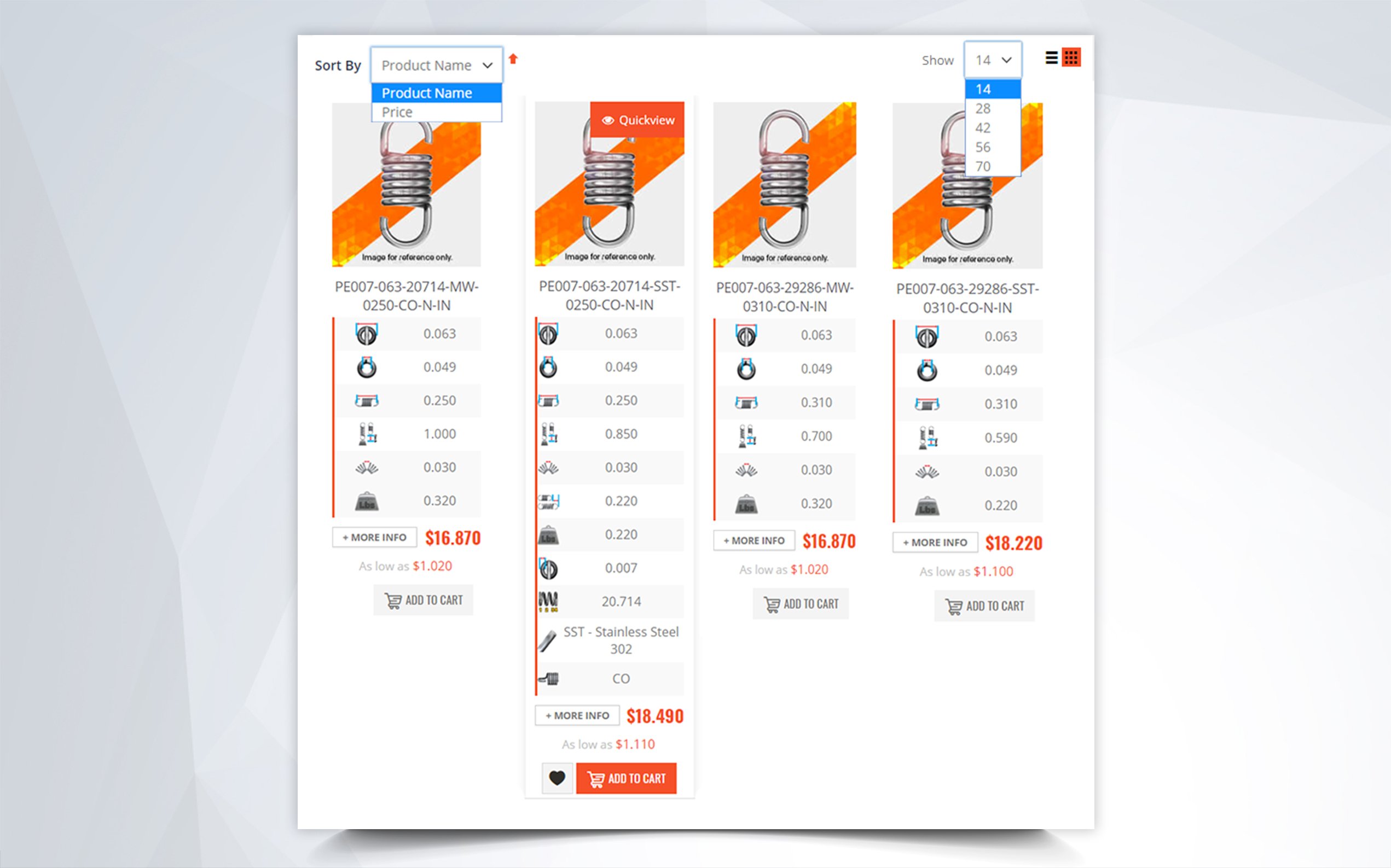

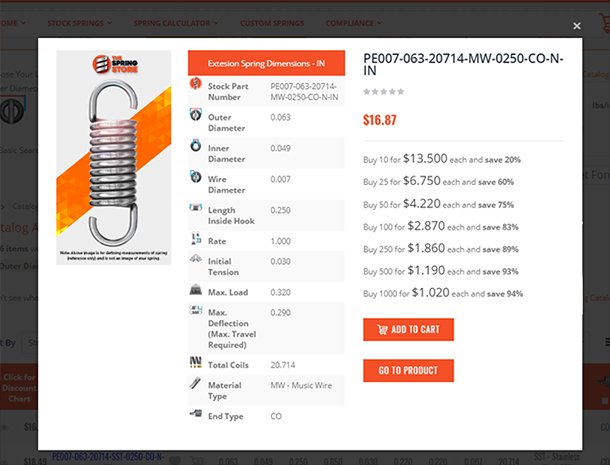

If you are looking to purchase an open or closed coil spring feel free to place your order online by selecting the springs you would like to buy and adding them to your cart. You may also call us directly to place an order over the phone: (951) 276-2777