Coil Springs and Vibration Damping: Innovations in Noise Reduction for Manufacturing

Coil Springs and Vibration Damping: Innovations in Noise Reduction for Manufacturing

Introduction

Noise and vibration in manufacturing settings not only pose significant challenges to worker safety and comfort but also impact the longevity of machinery and the quality of manufactured products. Coil compression springs, essential in vibration damping systems, have emerged as key solutions in addressing these challenges. This exploration traces the role of coil springs from their historical roots to modern applications and future possibilities, providing insights for professionals across manufacturing, engineering, and design sectors. By understanding the advancements and applications of coil springs in noise reduction, industry engineers can enhance operational efficiency and workplace conditions.

Historical Background

The journey of coil springs in vibration control commenced with the advent of industrial machinery, which introduced new levels of noise and mechanical vibration. Initially, manufacturers employed basic spring designs to mitigate these effects, primarily focusing on increasing comfort and reducing wear on machine components. However, as machinery evolved to become more powerful and complex, the demand for sophisticated vibration damping solutions grew. This need spurred the development of advanced coil compression springs, designed to handle diverse load specifications and frequencies, marking a significant shift towards more specialized noise reduction technologies in industrial environments.

Current Applications and Examples

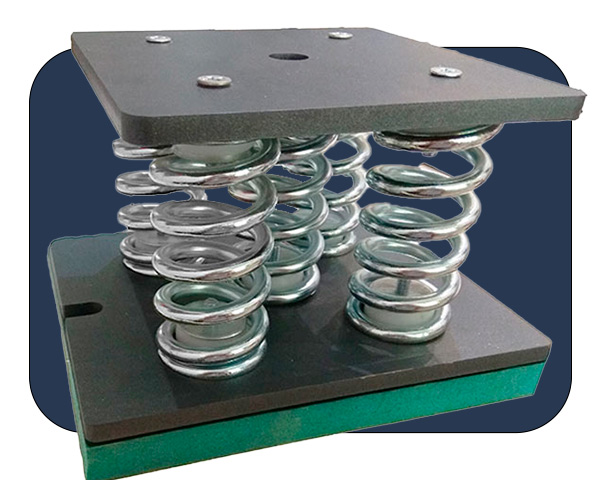

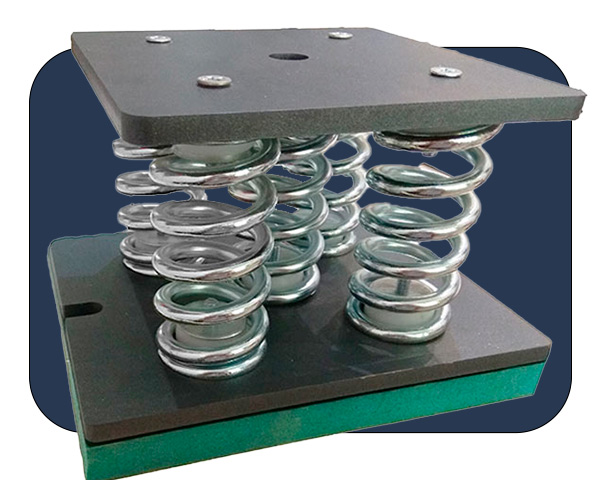

Today, the application of coil springs in manufacturing is widespread and varied, addressing vibration and noise issues in numerous types of machinery and equipment. In the context of modern manufacturing, these springs are integral to the design of anti-vibration mounts, machinery shock absorbers, and structural isolation systems. For instance, coil springs are pivotal in the automotive manufacturing industry, where they are utilized in assembly line equipment to minimize vibrations that could affect the assembly precision or worker safety. Additionally, in sectors like electronics manufacturing, where precision is crucial, coil springs in anti-vibration tables and mounts help maintain the stability necessary for the assembly of delicate components.

Example: An innovative application of helical coil springs is observed in the CNC (Computer Numerical Control) machining centers. These centers incorporate specially designed coil spring systems within their bases or as part of their cutting tool assemblies to dampen vibrations, leading to enhanced precision in cutting operations and extending the lifespan of the machining tools.

Technological Advancements and Innovations

The field of vibration damping has benefited greatly from advancements in coil spring technology, including the development of coil springs with adjustable stiffness and the introduction of composite materials to improve damping efficiency. Modern manufacturing and computational tools have transformed spring design from an empirical art into a precise science. The use of computational fluid dynamics (CFD) and finite element analysis (FEA) in spring design allows for the simulation of different operational scenarios, enabling engineers to tailor spring characteristics specifically to vibration and noise reduction needs. These technological innovations have significantly broadened the effectiveness and application range of coil springs in industrial vibration control.

Case Study: Consider a leading electronics manufacturing company that faced challenges with equipment vibrations disrupting the assembly process. By integrating coil springs engineered with variable force stiffness characteristics into their machinery, the company managed to significantly reduce vibration-induced errors by 87%, resulting in improved product quality and lower defect rates.

Design Challenges and Solutions

Creating effective vibration damping solutions with coil springs presents a set of unique challenges, including the need to match the dynamic properties of springs to diverse machinery and operational conditions. Engineers must carefully consider factors such as spring size, material, and force load capacity to design effective damping systems. Utilizing sophisticated design tools, such as Acxess Spring’s 3D CAD software, enables the detailed modeling and simulation of spring performance under varying conditions. Moreover, tools like Acxess Spring's Online Spring Force Tester are invaluable for validating designs and ensuring that they meet precise performance criteria, thereby optimizing the vibration damping capabilities of manufacturing equipment.

Future Trends and Potential

The future of coil springs in vibration damping is poised for further innovation, with trends leaning towards the integration of smart technologies and materials. Future developments may see the introduction of helical coil compression springs capable of dynamically adjusting their properties in response to real-time feedback from integrated sensors, offering unprecedented levels of vibration control. Additionally, advances in materials science promise the creation of springs that are not only more effective at noise reduction but also lighter, more durable, and environmentally sustainable, aligning with broader industry trends towards greener manufacturing practices.

Conclusion

The significance of coil springs in the landscape of manufacturing noise and vibration control continues to grow as machinery becomes more sophisticated and industry standards for worker safety and product quality become more stringent. Through a combination of historical knowledge, current applications, and forward-looking innovation, coil springs remain at the forefront of solutions enhancing the manufacturing environment. By leveraging advanced design and testing tools, industry professionals can continue to drive advancements in coil spring technology, leading to safer, quieter, and more efficient manufacturing processes.