Light Extension Springs

Definition: Extension springs which either have a light spring rate due to its physical dimensions or are light in weight.

Light extension springs will have small or average sized wire diameters with outer diameters proportionate in size in order to have a spring index no smaller than a 7 to 1 index. This is usually the main factor involving whether your spring is a light extension spring or not but other factors take place as well.

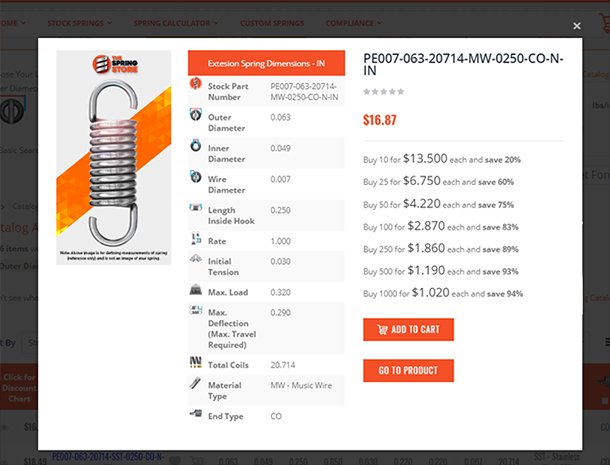

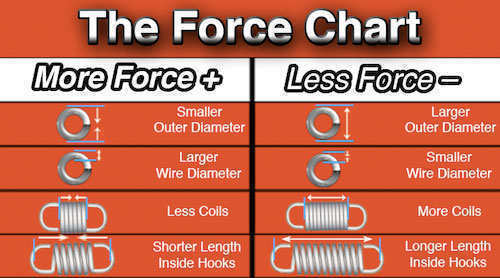

The force chart provided in this page lets you know how you can make a spring's rate stronger or lighter. You can see that to make it stronger, you must either decrease the outer diameter or increase the wire diameter. This will make the spring index tighter thus generating more stress amongst your extension spring's coils. You may also take some coils out by adjusting the length inside hooks or the hooks type for some longer hooks. On the other hand, to make your spring a lighter extension spring, you must decrease the wire diameter, increase the outer diameter, or add coils by making the length inside hooks longer or changing the hook type to shorter hooks (if applicable). As previously stated, decreasing the wire diameter or increasing the outer diameter will make your spring’s index larger thus relieving the extension spring’s coil from stress. This not only goes for force, though. The elastic limit of your extension spring is also affected by making these adjustments to its physical dimensions. Because, by making this spring stronger it becomes more stressed, it is also a stiffer spring which means that the elastic limit drops to a lower elastic limit. So if you need your light extension spring to travel more, you may follow the procedures to make it weaker.

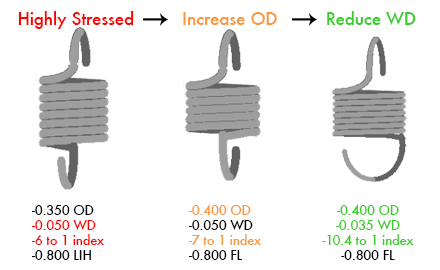

The image to the right shows how the proportion between your extension spring’s dimensions visibly affects its force and elasticity. You can see how spring index and the number of coils make a big factor. In the case of the coils, making the wire diameter thinner or thicker will also affect the coil count as most adjustments do. The first spring is highly stressed. It has a small outer diameter in proportion to its large wire diameter. At the length this spring has, you can see that the size of the wire diameter makes it so that it has very little coils. The next spring over is the same spring except we’ve made the outer diameter a bit larger. You can see already how it is becoming less stressed. The last spring is also the same spring but, in addition to making the outer diameter larger, we’ve also made the wire diameter thinner which has increased the number of coils. The only dimension remaining the same is the length inside hooks but we’ve got a totally different and lighter extension spring.

In terms of weight, to begin with, your shipping expenses will be more economical. The springs themselves go down in price because less material is required to cover the job. When it comes to the actual installation and productivity of your device or mechanism, if you have a mechanism or device that must be light, using light extension springs will definitely help. Light extension springs may also be small extension springs which will not take a lot of space.