Units for Spring Constant

Definition: The measuring units used to define and distinguish a coil spring’s constant or rate in both the metric and english system of measurement.

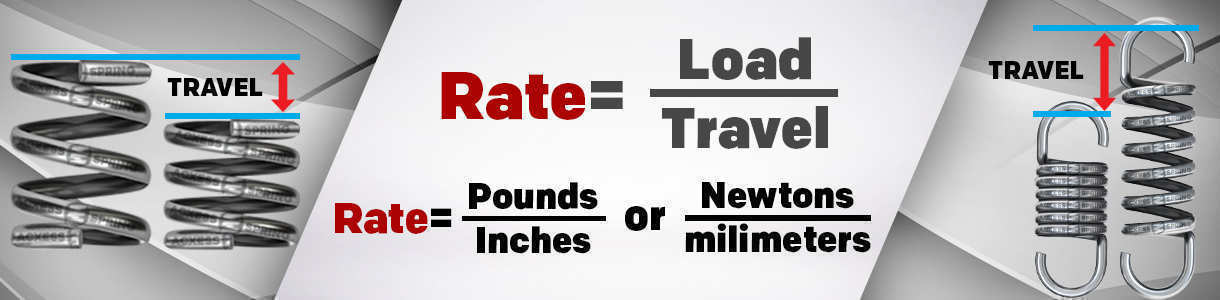

Spring Constant is measured according to the amount of force it takes for a spring to travel/deflect one full unit of measurement. Travel/deflection refers to the distance between the loaded length/height and the free length when a spring’s body is “deformed” to meet this required loaded length.

For Compression and Extension Springs

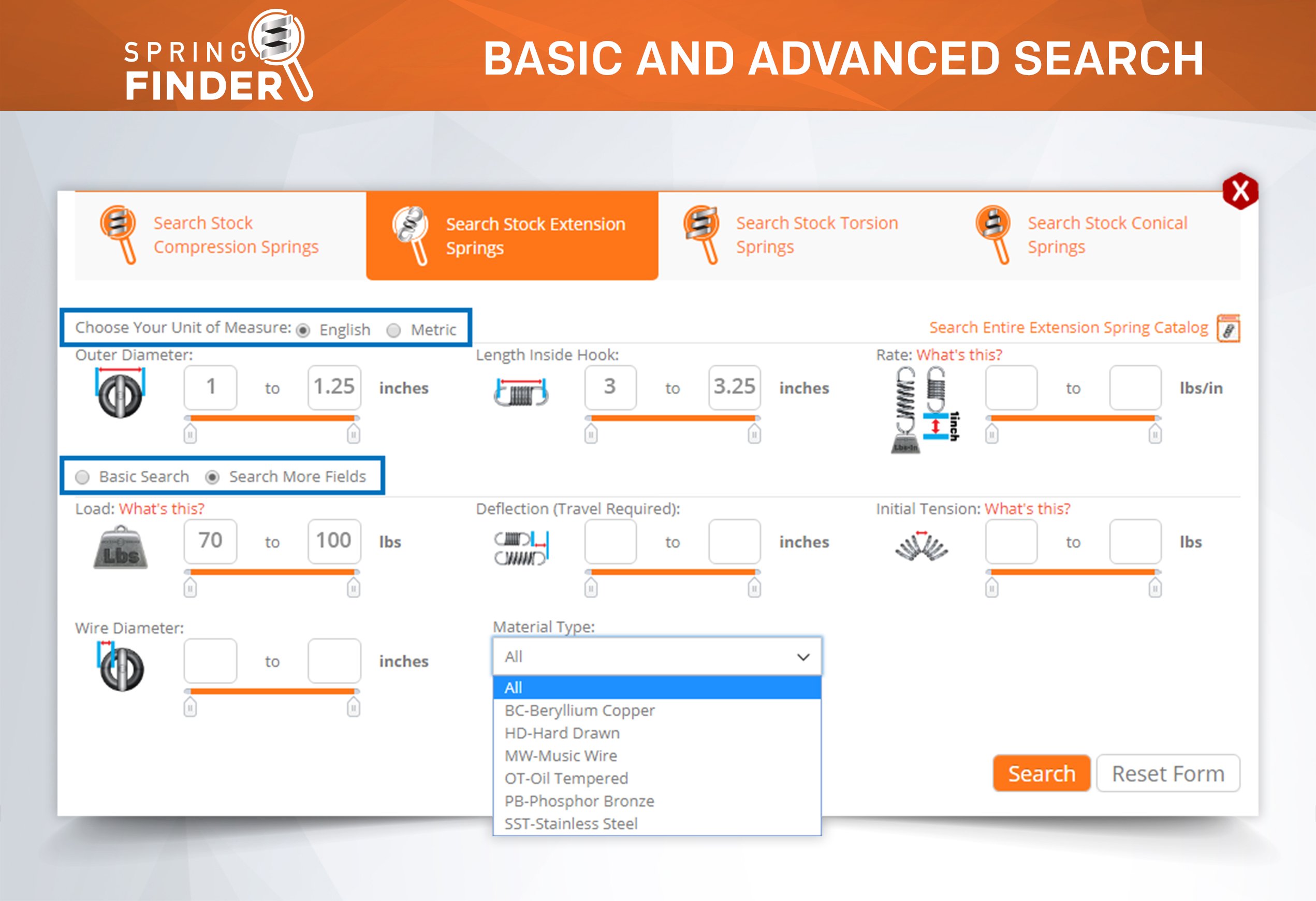

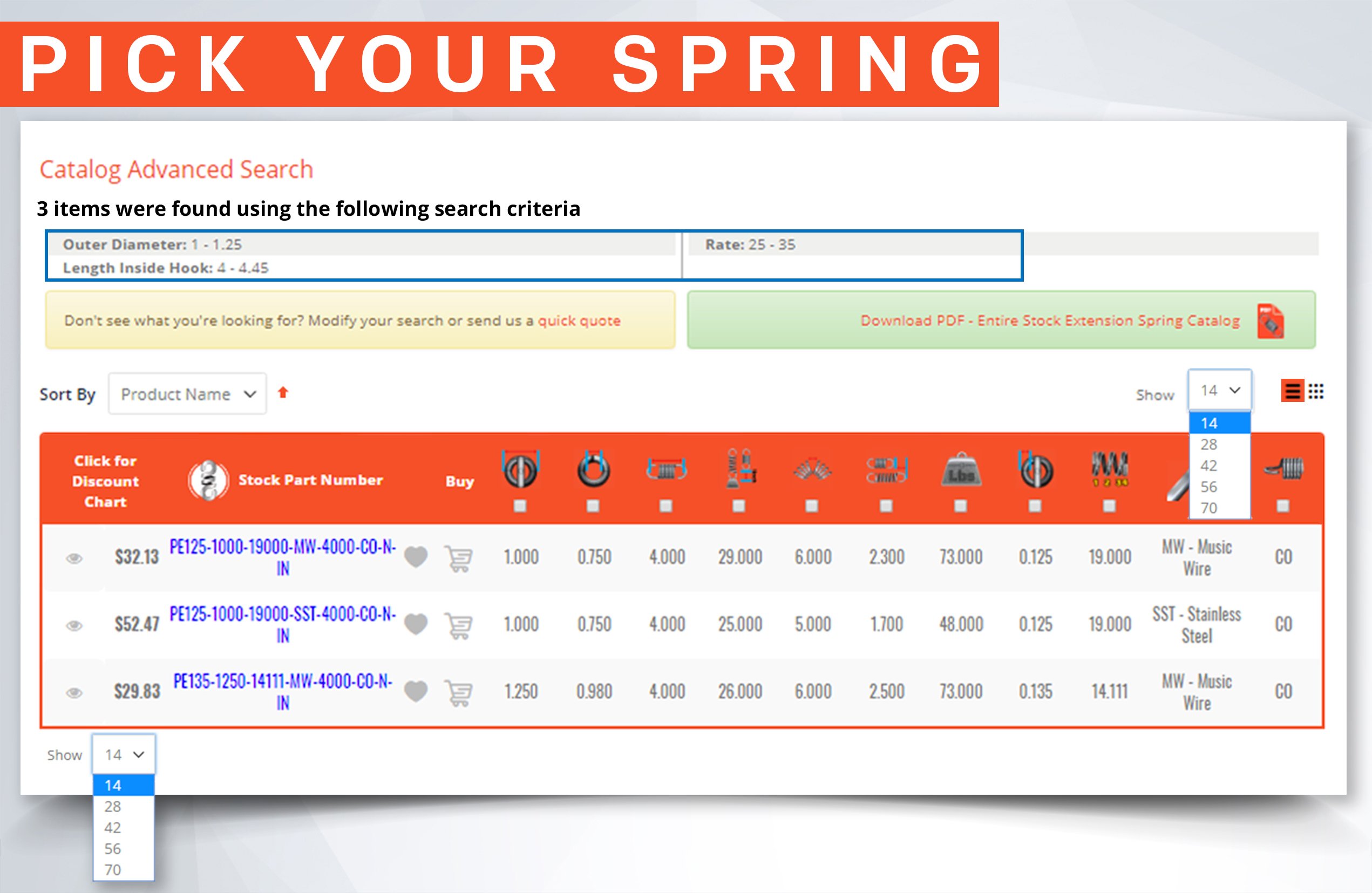

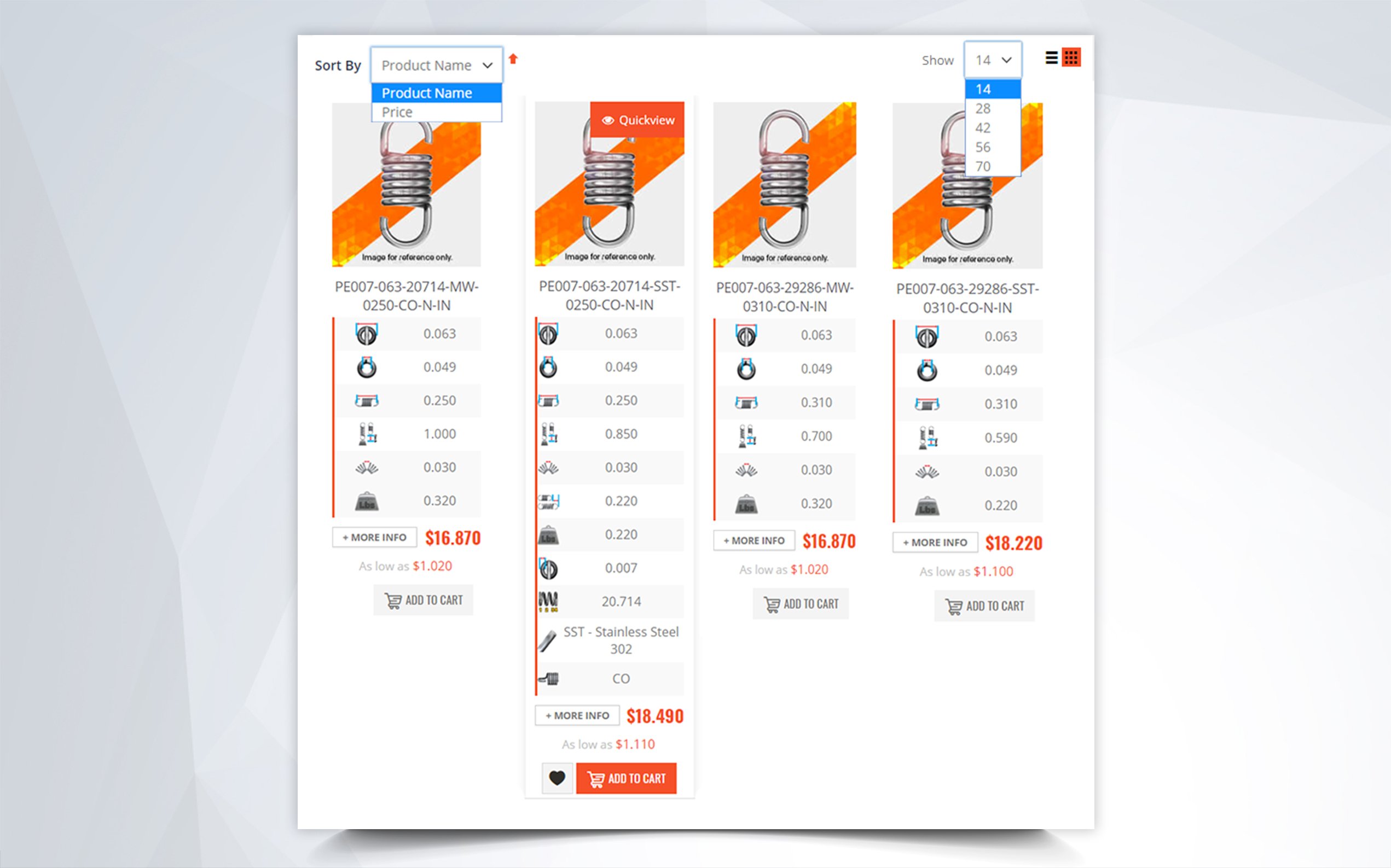

Compression and extension springs are both linear springs so their loads are measured in pounds (lb) while the travel is measured in inches (in or “). If the calculation is done using the metric units of measurement, the load is defined in Newtons while the deflection is measured in millimeters (mm).

The formulas to calculate a compression or extension spring’s rate is similar except in the case of an extension spring where initial tension is added to the equation. This is why we’ve provided you with two diagrams below to explain the difference.

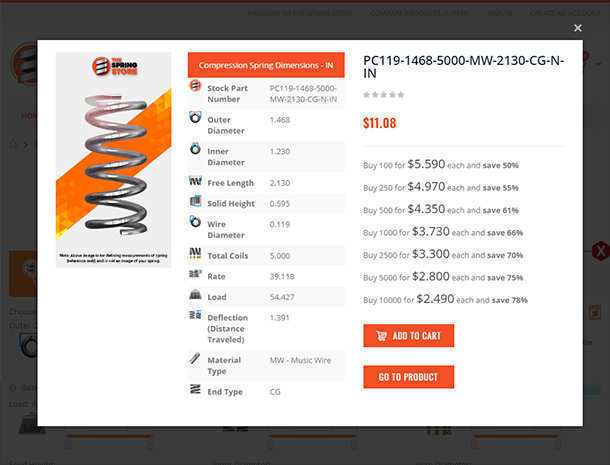

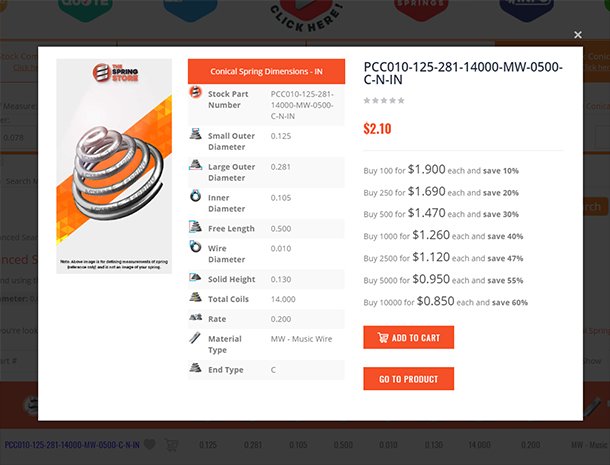

Compression Spring Constant Units

To calculate the required spring rate for both metric and english spring constant units, you must divide the load by the distance traveled. The load is the amount of force in pounds or Newtons that’ll make your spring deflect to your desired loaded height. The travel is the distance between your spring’s free length and loaded height in inches or millimeters. Dividing these two values will give you your spring’s rate in pounds per inch or Newtons per millimeter.

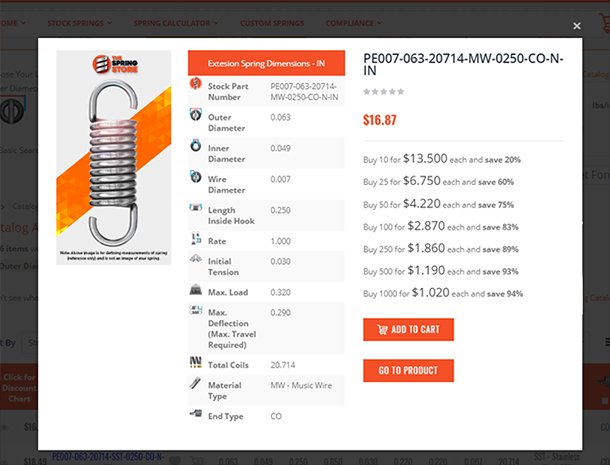

Extension Spring Constant Units

To calculate the required spring rate of an extension spring you must consider initial tension which is measured in either pounds or newtons. This value is additional to the spring rate calculation which is why you will still divide the load by the travel but now you will add the initial tension in pounds or Newtons. Therefore, you will follow the compression spring rate formula and then add the initial tension.

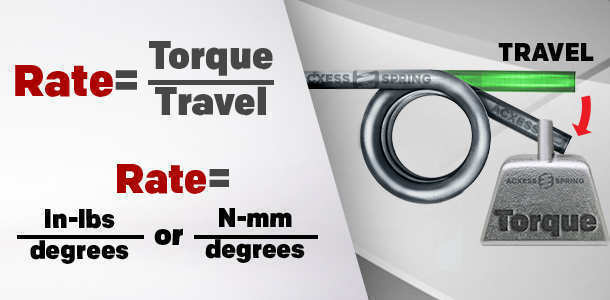

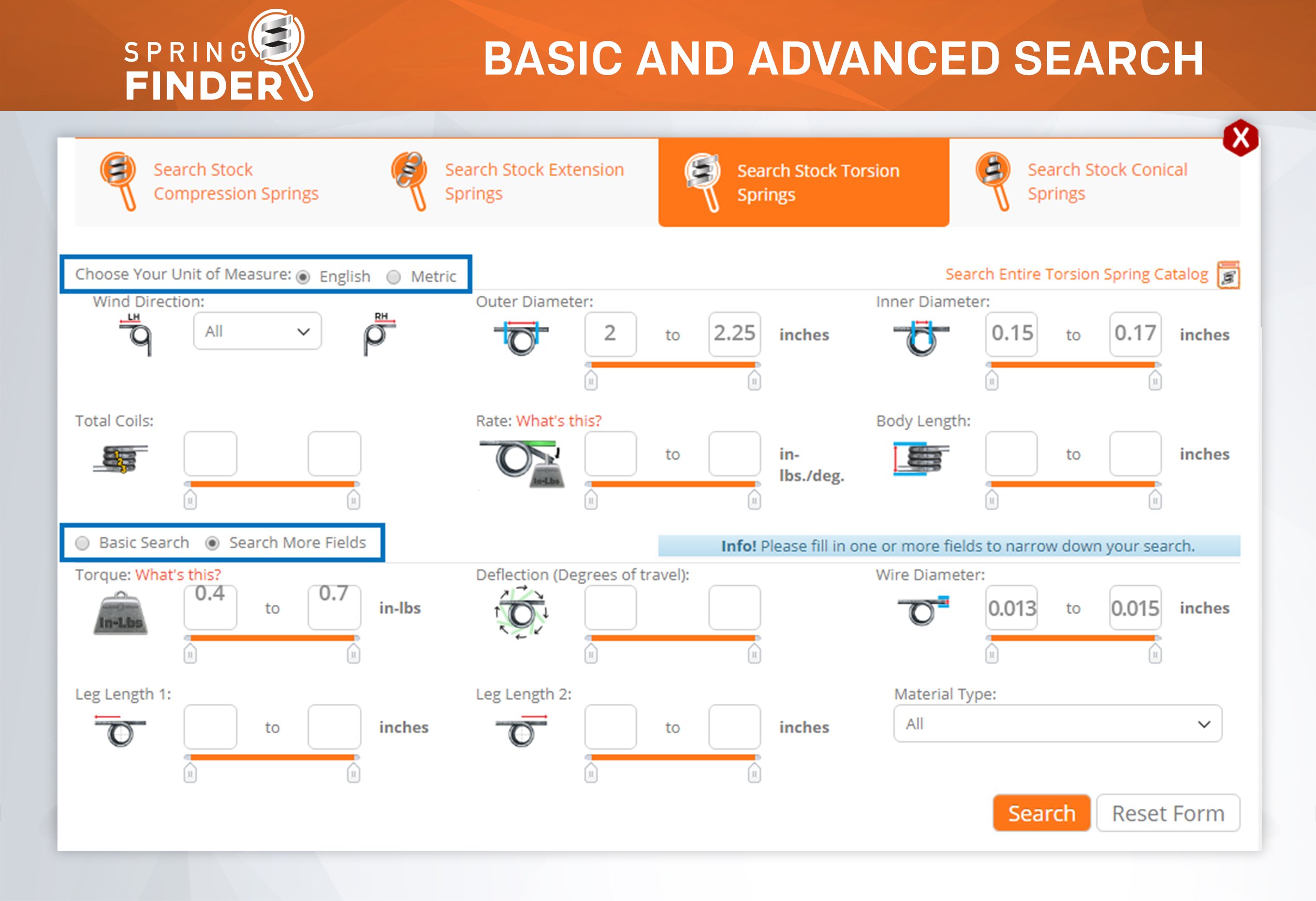

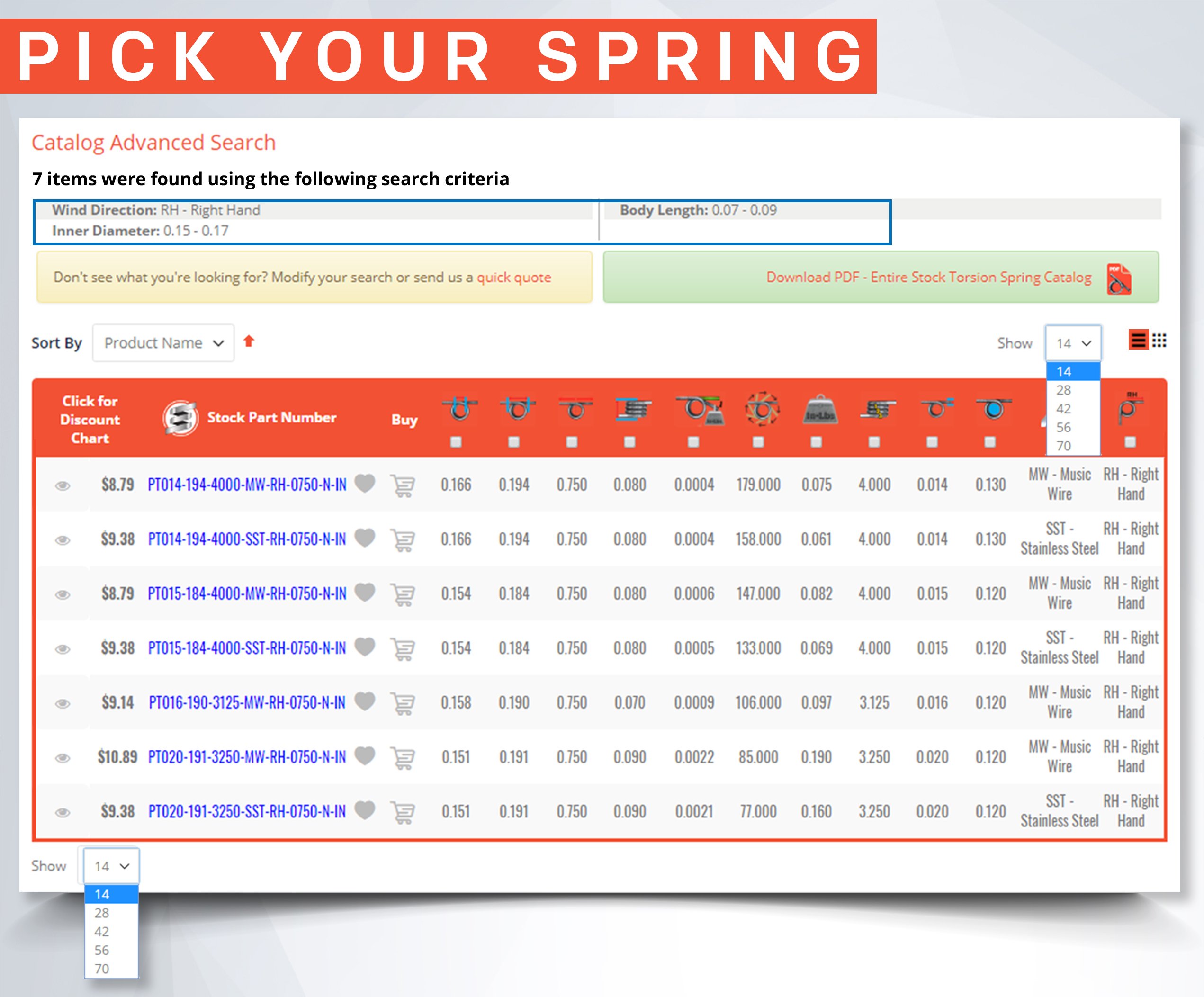

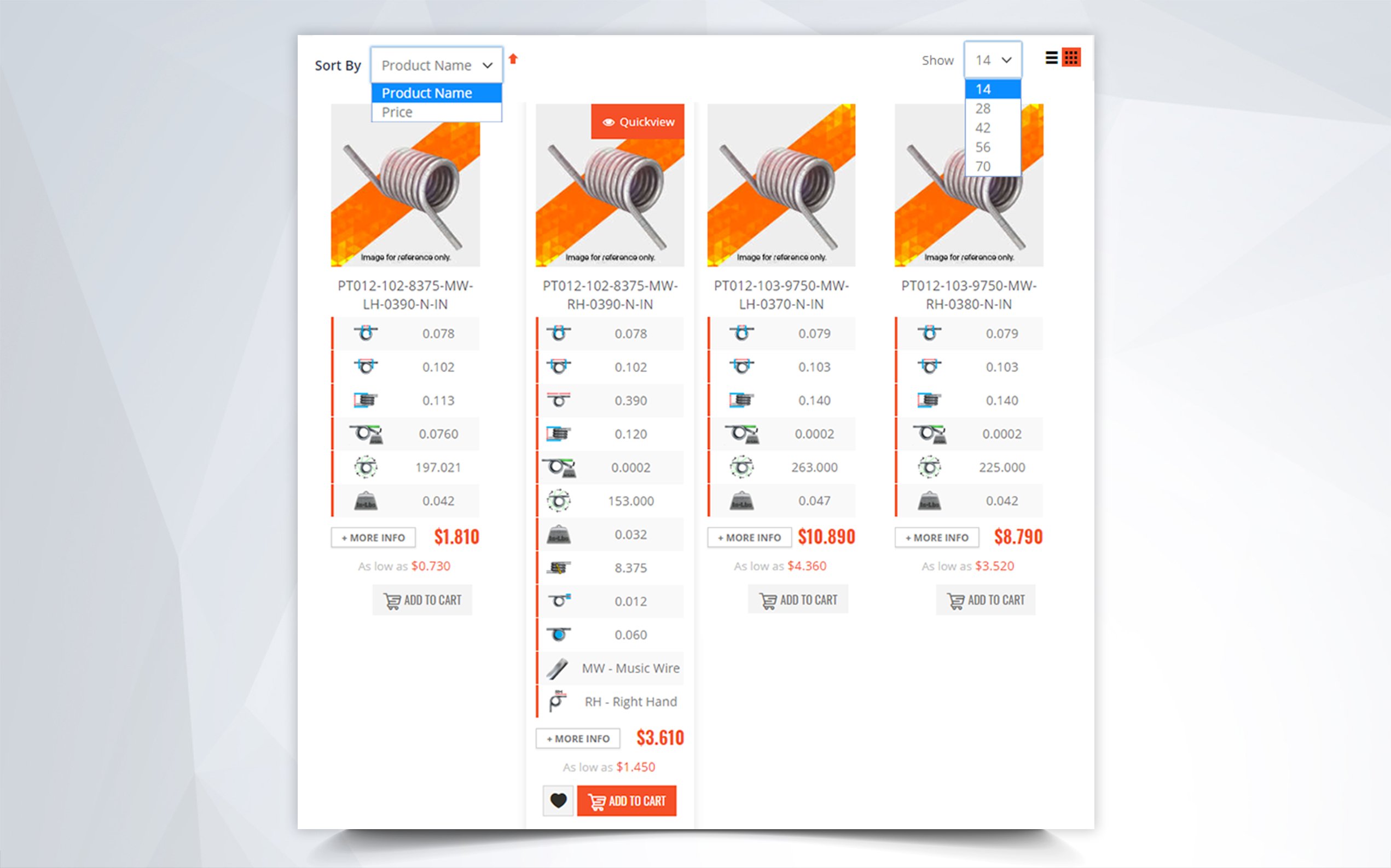

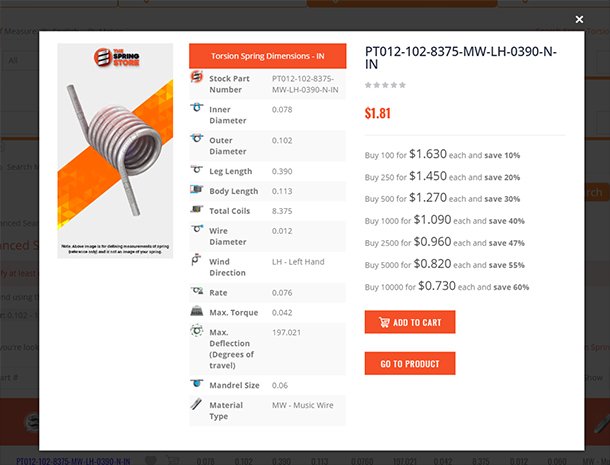

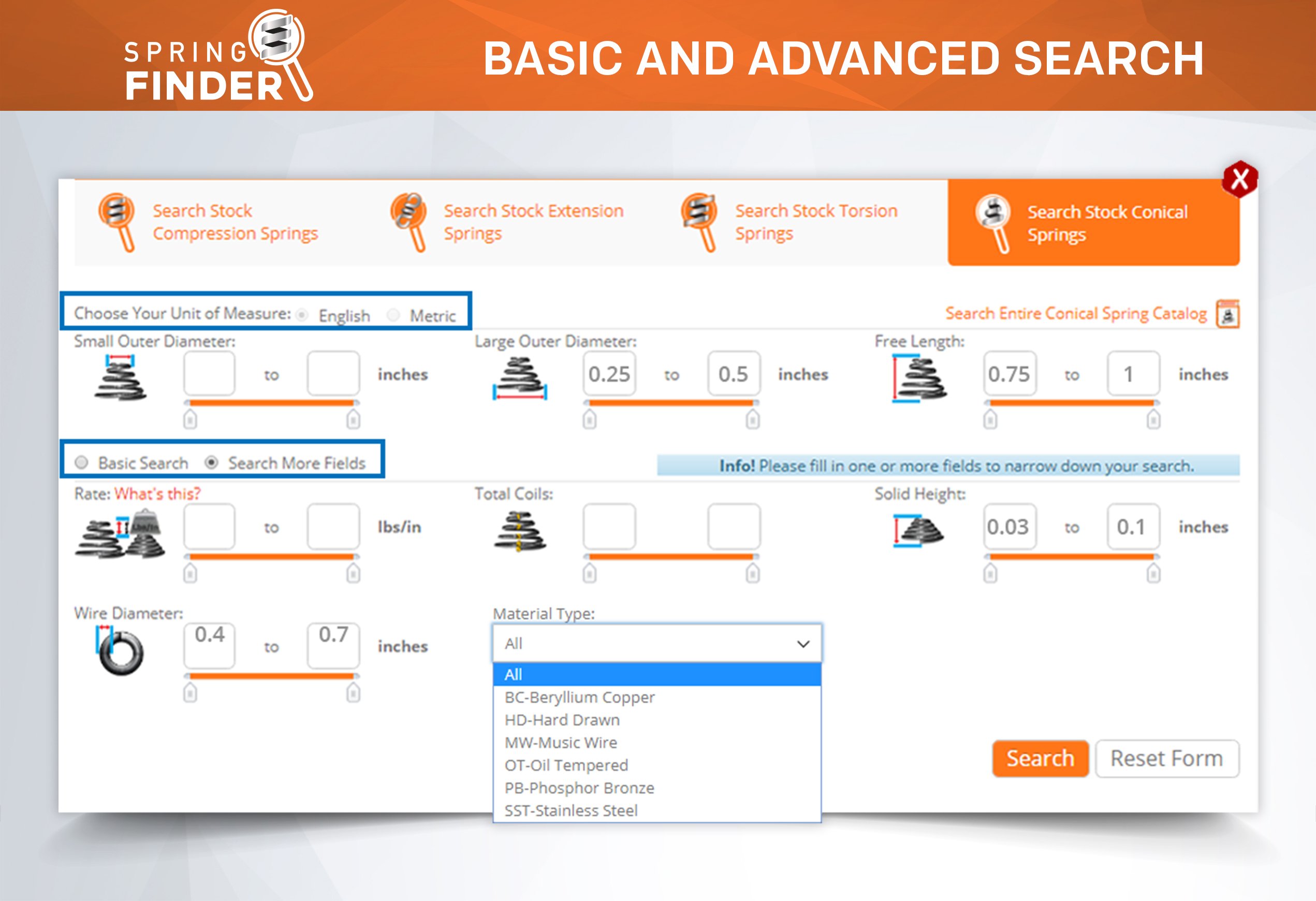

Torsional Spring Constant Units

When it comes to torsional springs, they eject a radial force. The torsion spring’s legs are meant to be pushed by a specific torque to achieve a required deflection. The required torsion spring rate is calculated the same way that it is calculated for compression and extension springs but, since this is a radial force and not a linear one, units for spring constant are different.

To calculate the required torsion spring constant you must divide the torque in inch-pounds or newton-millimeters by the degrees of deflection thus leaving you with a torsion spring rate result measured in inch-pounds per degree or newton-millimeters per degree.