The Art of Miniaturization: Springs in Electronic Devices

The Art of Miniaturization: Springs in Electronic Devices

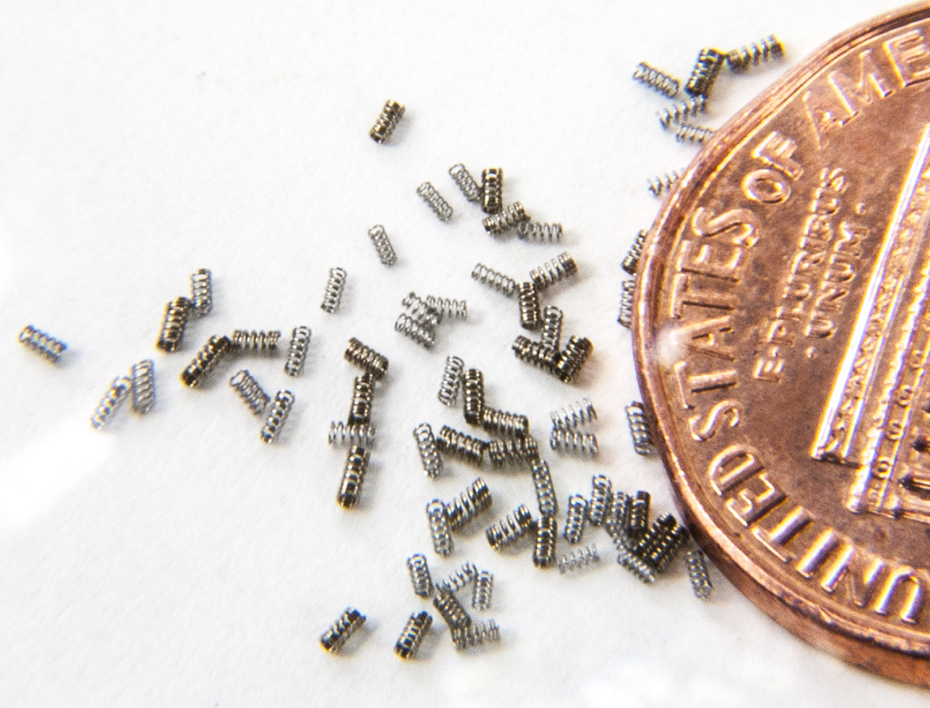

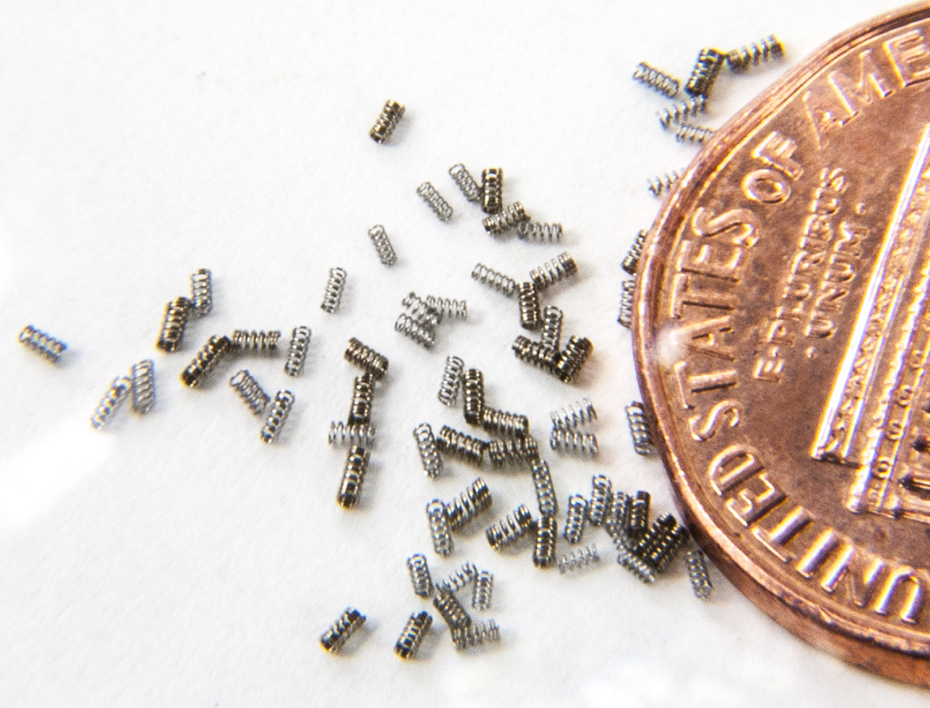

In an era where technology's mantra is "smaller, faster, smarter," the quest for miniaturization in electronic devices has become a central theme of innovation. This relentless pursuit not only demands ingenuity in spring design but also in the selection and engineering of every component, no matter how minuscule. Springs, though seemingly trivial, are essential in the mechanical and electrical functionality of myriad devices. From ensuring the tactile response of a smartphone button to maintaining the reliable contact of a battery, springs play a crucial role. This exploration into the world of springs reveals their historical significance, modern applications, inherent design challenges, and the pioneering tools that are setting new standards for innovation.

The Historical Evolution of Springs in Electronics

The journey of compression springs within the realm of electronics is a rich narrative of adaptation and innovation. Initially reserved for mechanical applications like clocks and watches, small springs found their way into early electronic devices as technology evolved. The transition from mechanical to electronic required springs to become smaller, more resilient, and significantly more precise. This evolution was not merely a matter of scale but a complete reimagining of their role and capabilities. The development of microsprings and the incorporation of Micro-Electro-Mechanical Systems (MEMS) technology marked a significant milestone, showcasing springs' versatility and indispensability in the miniaturization trend. Through decades of technological advancements, small springs have been continuously refined, embodying the progress of electronic devices themselves.

The Role and Importance of Springs in Modern Electronic Devices

In contemporary electronic devices, springs are omnipresent, serving a myriad of crucial functions. Beyond the obvious mechanical roles like providing push-back in button presses, springs are integral in ensuring constant electrical connectivity, such as in battery compartments where they compensate for size variations and prevent power interruptions by constantly providing spring pressure on the contact point. Their utility spans across various sectors, including medical devices where reliability can mean the difference between life and death, and in aerospace applications where extreme conditions test their durability and performance. The unique combination of conductivity, resilience, and precision that springs offer makes them indispensable in the electronics industry, highlighting their importance beyond their simple mechanical nature.

Design Challenges in Spring Miniaturization

The engineering of springs for electronic devices is a complex balancing act that pushes the limits of materials science and precision manufacturing. Designers face the challenge of creating springs that are not only small, but also capable of performing reliably under the stress of constant use. This requires an intricate understanding of spring materials that can maintain elasticity and strength at microscales, and the development of manufacturing processes that can achieve such precision consistently. Furthermore, springs must be designed to resist corrosion and maintain excellent electrical conductivity over their lifetime, adding layers of complexity to their design and production. These challenges are a testament to the critical role springs play in the success of electronic devices, where even the smallest components can have a significant impact on overall performance and reliability.

Innovations in Spring Technology

Innovations in spring technology have often led to breakthroughs in electronic device design and functionality. For example, the use of advanced alloy springs in smartphones has not only improved their mechanical responsiveness but has also contributed to the devices' overall structural integrity and user experience. Similarly, the development of micro-electromechanical systems (MEMS) has enabled the integration of microscopic springs into chips, allowing for new types of sensors and actuators that can perform mechanical functions at the microscale. These case studies exemplify how innovative spring designs can solve complex engineering challenges, enabling new functionalities and enhancing device performance.

Testing in Spring Design

The innovation in spring design is complemented by advancements in testing and simulation technologies. Spring Creator 5.0 exemplifies this progress, offering designers a powerful tool for simulating and optimizing spring designs before physical prototypes are manufactured. This software allows for the precise calculation of spring dimensions, load capacities, and life cycles, reducing the time and cost associated with trial-and-error testing. The Online Spring Force Tester further enables accurate measurement of a spring's force characteristics, providing essential data for validating design assumptions and ensuring that the final product meets the required specifications. These tools are invaluable for engineers looking to push the boundaries of spring design and application in electronic devices.

Conclusion

While often overlooked, springs are a testament to the ingenuity and precision required in the electronics industry. From their historical origins to their indispensable role in modern devices, springs embody the challenges and triumphs of miniaturization. As technology marches on, the innovation in spring design and testing will remain at the forefront, enabling the next generation of electronic devices to be smaller, more reliable, and more capable. For engineers and designers, the journey of springs in electronic devices is not just a story of past achievements but a beacon for future innovation, inviting continuous exploration and redefinition of what is possible.

In navigating the complex landscape of electronic device manufacturing, the attention to detail, creativity, and rigorous testing embodied in spring technology offer valuable lessons. By embracing these challenges and opportunities, the industry can continue to push the boundaries of technology, making the next leap in miniaturization not just a possibility, but a reality.